Contents

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Included items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

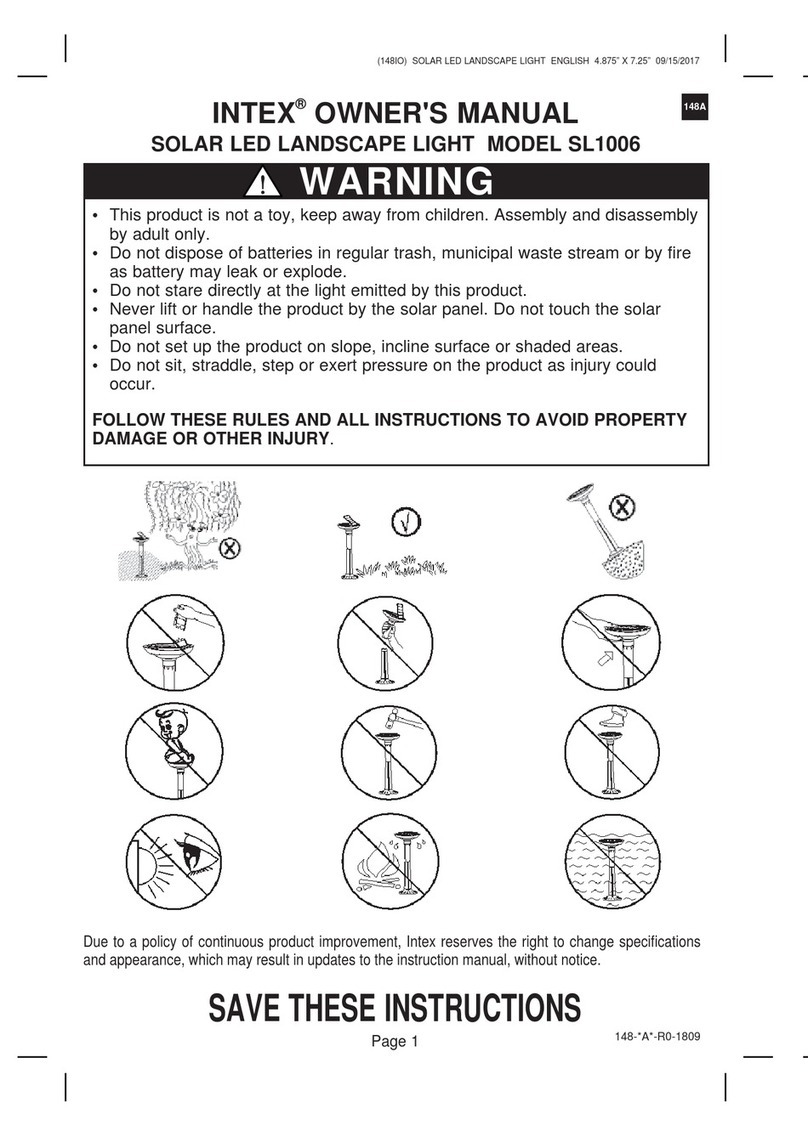

2. Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Eliminating fire risk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Protecting the public . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

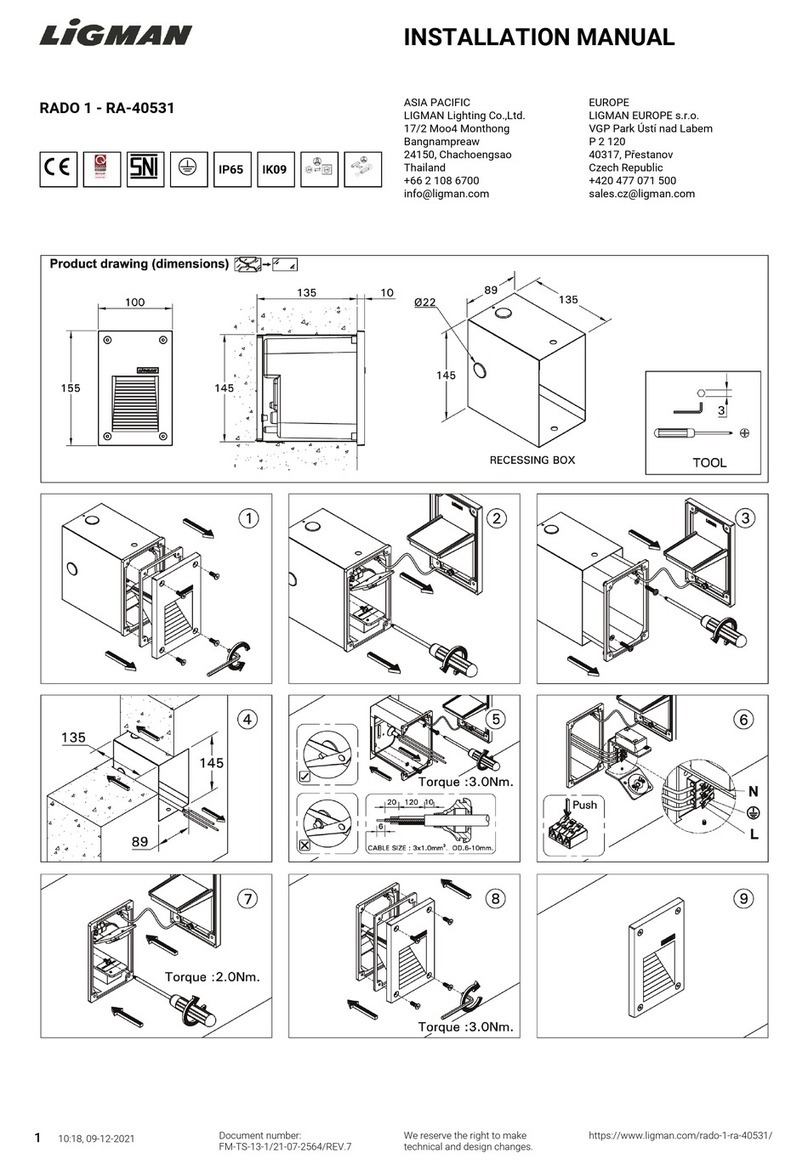

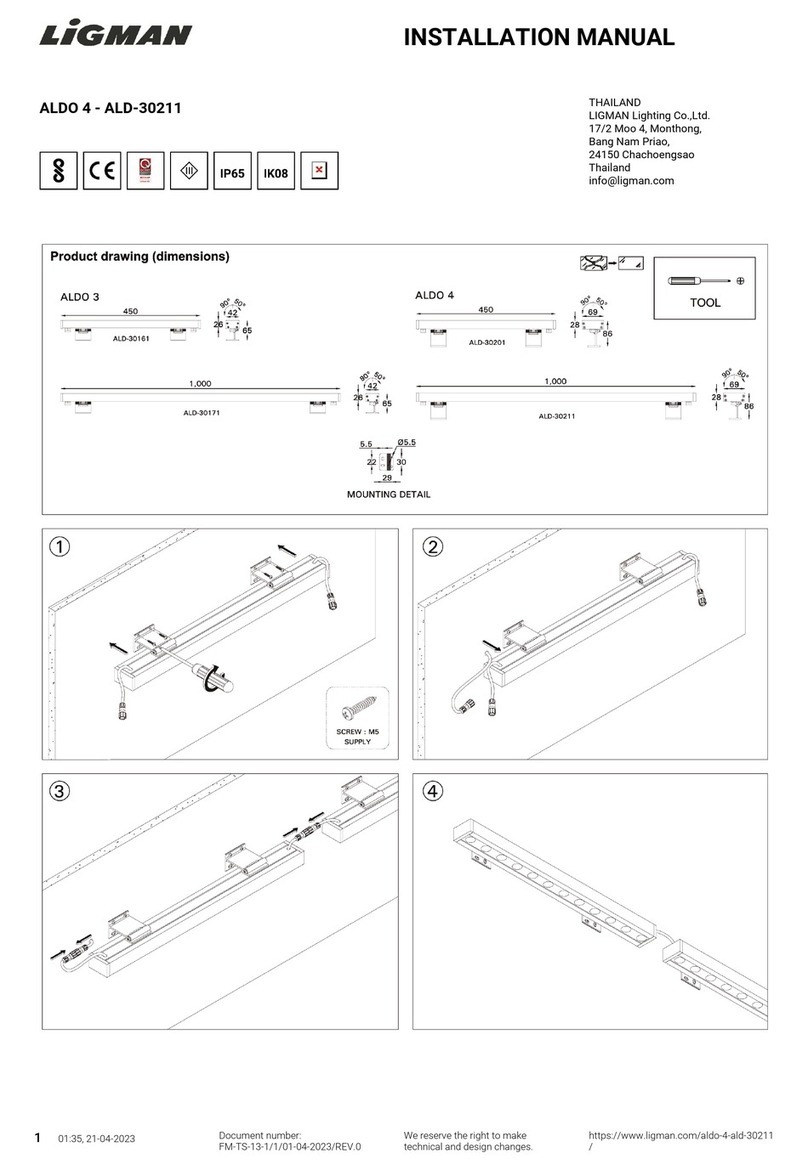

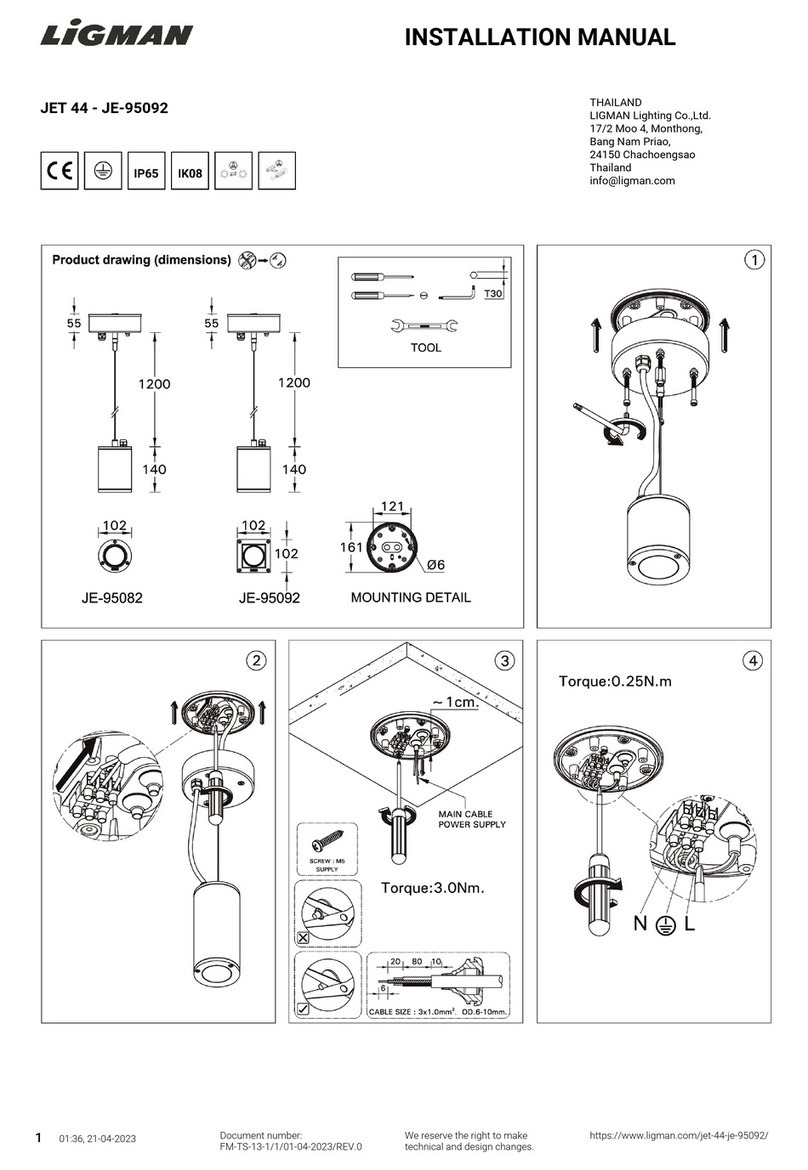

3. Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

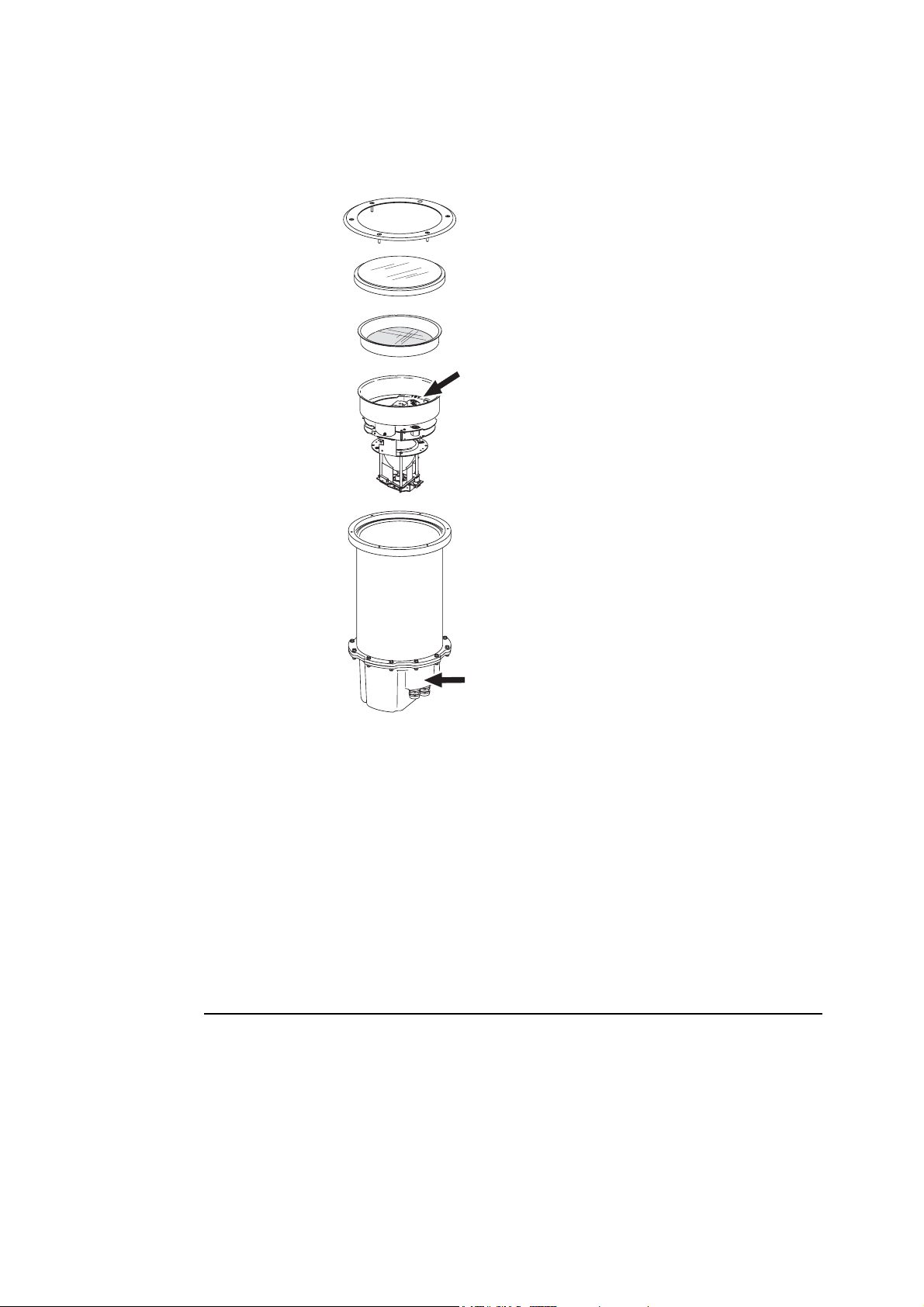

4. Exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

5. Groundwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Choosing a location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Stability and weight-bearing capacity . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Water resistance and drainage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Disturbance by roots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Service access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Installation options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

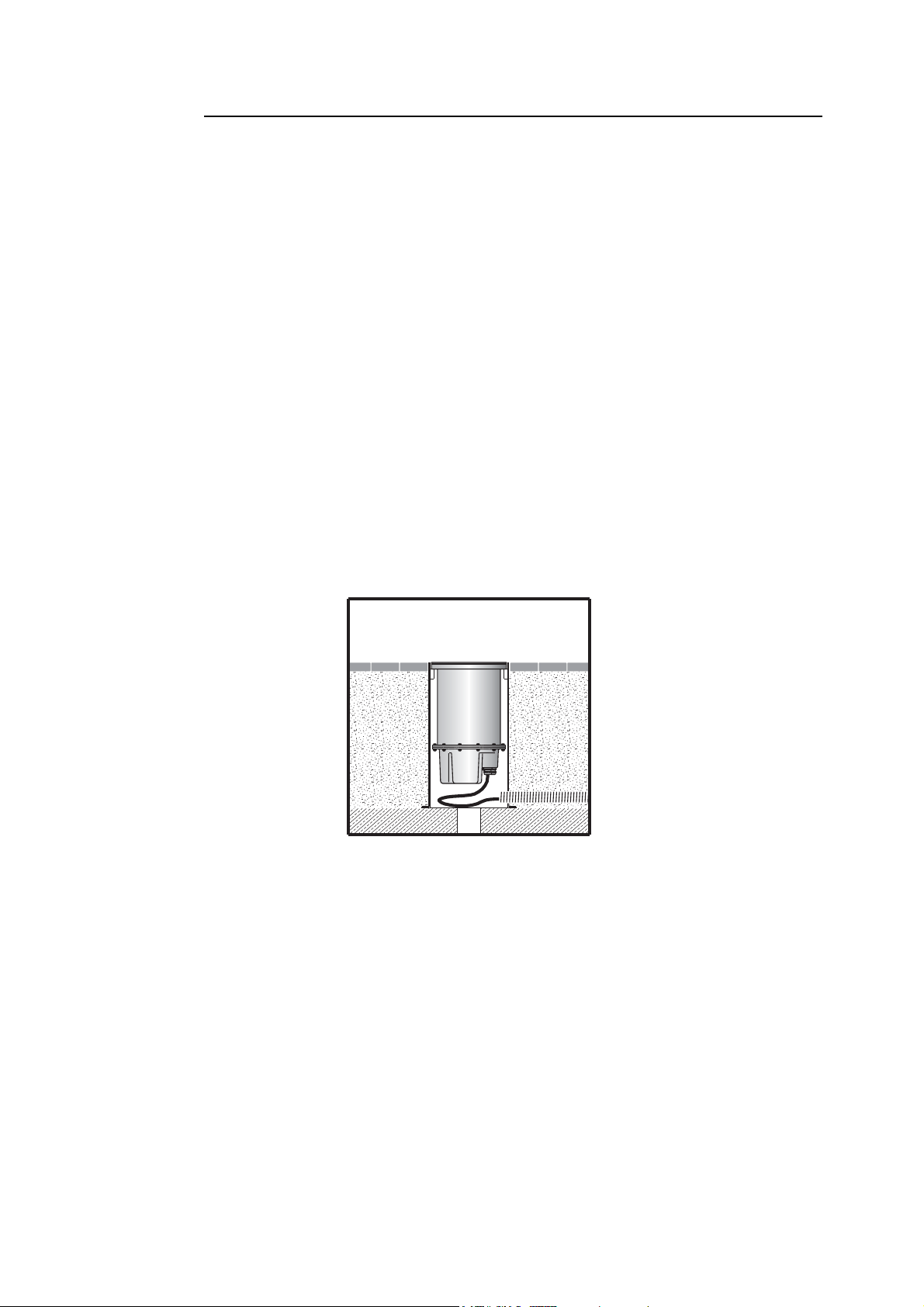

1. Installation sleeve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Sleeve installation: example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Temporary installation sleeve cover. . . . . . . . . . . . . . . . . . . . . . . . 9

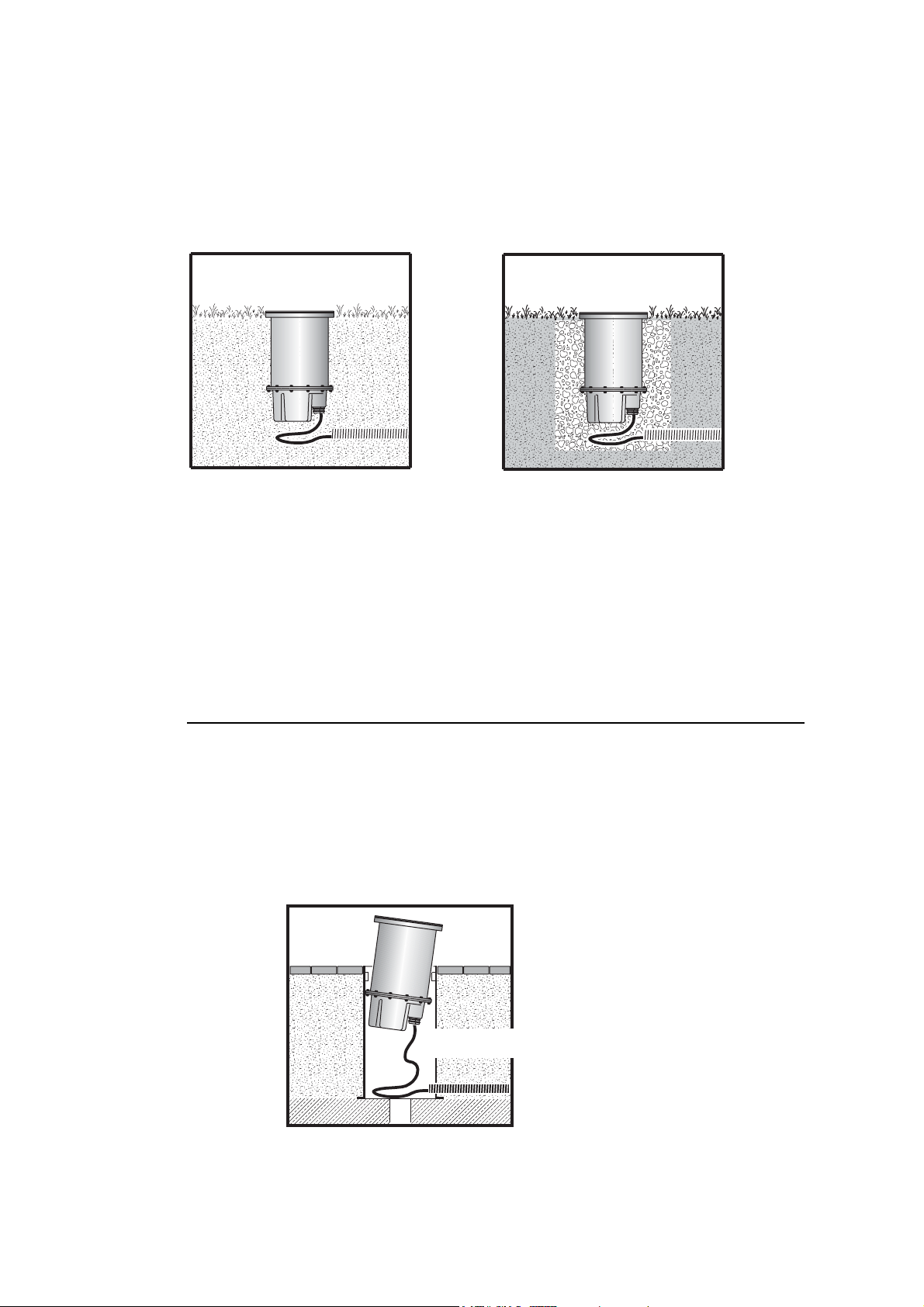

2. Direct burial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Direct burial: examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cable installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Cable slack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6. Power and data connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

AC power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Power supply settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Cable glands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Connecting power supply cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Control data cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Planning cable layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connecting control data cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7. Powering on for the first time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6 Color model test program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Full Spectrum CMY model test program . . . . . . . . . . . . . . . . . . . . . . .15

8. Set-up and adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Beam adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Condensation and humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

9. Component removal & reinstallation . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Front glass and lens: removal and refitting . . . . . . . . . . . . . . . . . . . . . . .17

Refitting the lens and front glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Lamp module: removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

10. Installation specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19