Masalta MPG3215 User manual

1

TableofContents

1.SAFETYINFORMATION

1.1SafetyPrecautions .. .2

1.2OperatingSafety ....3

1.3OperatorSafetywhileusing InternalCombustion Engines ..4

2. OPERATION

2.1OperatingPrinciple ..5

2.2DeliveryChecks ..5

2.3BeforeStarting .. ...5

2.4ToStart ..5

2.5ToStop ... ..6

2.6 Operation .... ......6

2.7WhenOperationisFinished .. .........6

3.MAITENANCE

3.1 PeriodicMaintenanceSchedule .. 7

3.2Lubrication .. .7

3.3SparkPlug 8

3.4AirCleaner 8

3.5Transporting .... 8

3.6Storage .... .......8

3.7TroubleShooting ...9

4.TECHNICALDATA ... .. ..10

5.WARRANTY ..... .11

6.MAINTENANCERECORD .....12

2

SAFETYINFORMATON

1.1SafetyPrecautions

Beforeoperating themachine,readboththemanualandtheenginemanual

carefullytobecomefamiliarwiththelocation and properuseofall controls.Do

notallowuntrainedorunauthorizedpersonnel,especiallychildren,tooperate

thismachine. Useonlythepartsauthorizedbythefactoryforservice.

ThismanualcontainsDANGER,WARNING,CAUTIONcallouts

whichmustbefollowed toreducethe possibilityofpersonalinjury,

damagetotheequipment, orimproperservice.

Thisisthesafetyalertsymbol.Itisusedtoalertyou topotential

personalinjuryhazards. Obeyall safetymessagesthatfollowthis

symboltoavoidpossibleinjuryordeath.

DANGERindicatesahazardousprocedurewhich,if notavoided,

will result inseriousormortalinjury.

WARNINGindicatesadangerorhazardousprocedurewhich,if

notavoided,couldresult inseriousormortalinjury.

CAUTIONindicatesadangerorhazardousprocedurewhich,if

notavoided,couldresultindamagetomachineryormoderate

injury.

!

!

DANGER

!

WARNING

!

CAUTION

3

SAFETYINFORMATON

1.2Operating Safety

lDONOTmodifythe machine withoutthe priorconsentofthemanufacturer. We

do not assumeresponsibilityforanyaccident duetoequipment modification.

lNEVERoperatethemachineinpurposeforwhichit isnot intended.

lNEVERallowanyone tooperatethe machinewithoutpropertraining.People

operatingthemachinemustbefamiliarwiththerisks andhazardsassociated

withit. Andfamiliarwiththesafetyprecautionsandoperationtechniques.

lALWAYSoperatethemachinewithall safetydevicesandguardsinplaceandin

working order.

lALWAYSwearappropriateclothing,wearhearingandeyeprotectionwhen

operatingthemachine.

lDONOTusethemachine nearflammablematerialorinexplosiveenvironments.

The exhaustpipecanget veryhotduringoperation.Sparkscanbe emittedfrom

it, and thesecanigniteflammablematerial.

lALWAYSkeeptheareaaroundthemufflerfreeof debrissuchasleaves,paper,

carton,etc.Ahot mufflercouldignitethedebrisandstartafire.

lALWAYScheck thatall controlsarefunctioningproperlyimmediatelyafter

start-up. DO NOToperatethemachineunless all controlsoperatecorrectly.

lNEVERoperatethemachinewiththefuelcaplooseormissing.

lNEVERtouchtheengine,exhaustsystemofthemachine.Theyareextremely

hotduring operation.

lDO NOTtouchtheV-beltandtherotatingpartsduring operation.

lDO NOTcleanorservicethemachinewhenit isrunning.

lNEVERusethe defectiveparts.

lALWAYSkeepthemachine cleanandlabelsclear.

lNEVERleavethemachinerunningunattended.

4

SAFETYINFORMATION

1.3OperatorSafetywhileusing InternalCombustion Engines

lDO NOTsmokewhenrefueling theengineoroperatingthe machine.

lDO NOTrefuelahot orrunningengine.

lALWAYSkeep awayfromall hotorspark-generatingobjectswhen refuelthe

engine.

lALWAYSrefill thefueltankuntil the machine hascooled,andinawell-ventilated

environments.

lDO NOTspill fuelwhen refuelingthe engine.

lALWAYStakecaretousetherighttypeoffuel.

lALWAYSinspect the fuelleakageregularly.

lNEVERperformanyworkonthemachinewhileitisrunning.Beforeworkingon

it, stoptheengineand disconnectthesparkplug wiretopreventaccidental

starting.

lAvoidprolongedbreathingofexhaust gases.

lALWAYStransportandhandlefuelonlywhencontainedinapprovedsafety

containers.

lAvoidtouchorleanagainsthot exhaustpipes.

lAllowengine tocoolbeforeperforming anyrepairsorservice.

lALWAYSkeeptheareaaroundthemufflerfreeof debrissuchasleaves,paper,

cartons,etc.Ahot mufflercouldignitethedebrisand startafire.

lNEVERrun theenginewithoutairfilter.

5

OPERATION

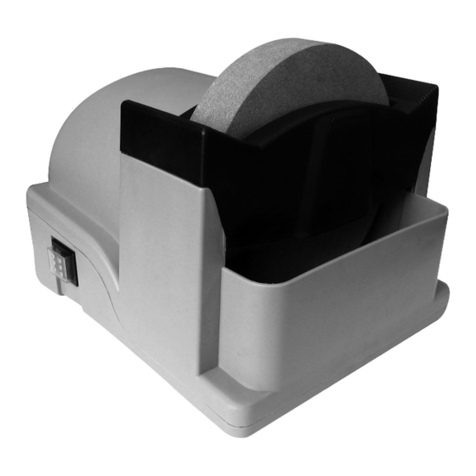

2.1Operating Principle

The followinginstructionswerecompiled toprovide youinformation on howtoobtainlong

and troublefree useofthemachine.Periodicmaintenanceofthe machine isessential.

Read the manualcarefullyand thoroughlyfamiliarizeyourself withthe machine and all it’s

functions. Failuretodosomayinjureyourselforabystander.

2.2DeliveryChecks

Immediatelyontakingdeliveryofyournewmachine and beforeputtingit intoservice.

lRead theoperation manualcompletely—itcouldsaveagreatdealofunnecessary

expense.

lRead theengine manualsupplied.

lCheck the generalcondition ofthe machine –hasitbeen damaged duringdelivery?

lCheck engine oil level.

lCheck fuellevel.

2.3BeforeStarting

Beforestartingthe machine, check the followingitems:

lAll controlleversareinthe neutralposition.

lAll bolted jointsaretightened.

lFuellevel.

lOil levelinthe engine

lAircleanermaintenanceindicator.

lCheck the tension and conditionofthe V-belt.

lALWAYSinspect vibratinghead fordamagetothreads.

NOTICE: Check theoil levelintheengine beforestarting.The warrantiesareVOIDifthe

machine run without oil.

2.4ToStart

Beforestartingthe machine must knowthe location and function ofall controls.

1Tostart acoldengine,movethe chock levertotheCLOSEDposition.

Tostart awarmengine, leavethe chock leverinthe OPENposition.

2Press the primingbulbrepeatedlyuntil fuelcan beseen intheclear-plasticfuel-return

tube.

3Turnthe engine switchon the equipment tothe ONposition.

4Pull the startergriplightlyuntil youfeelresistance,then pull briskly.Returnthestarter

gripgently.

5Ifthe chock leverwasmoved totheCLOSEDposition tostarttheengine,gradually

moveit tothe OPENposition asthe engine warmsup.

6

OPERATION

2.5To Stop

1Movethe throttlelevertotheMINposition.

2Turnthe engine switchon the equipment tothe OFF position.

2.6Operation

1Keepthe bendingradiusofthe flexiblehosetoaminimumduringuse.

2DONOTstartthe machine withthe vibratorhead immersed inthe concretemix.Afterthe

engine machine hasstarted, immersethe vibratorhead quicklyintothe concretemix.

3NEVERturnthe vibratoroffwhen it isimmersed inthe concrete.

4When movingaround the jobsite,do notdragthe vibratorhead and shaft ontheground.

5DO NOTallowthe headtovibrateagainst alreadyhardened concreteorsteelusedin

reinforcement.

6NEVERdroporknock the vibratorhead against anyhardobjects.

7When the vibratorisoutofthe concretemixforextendedperiod oftime,allowthe

engine toreturntoidlespeedorsimplyturnthe machine off.

8Aftereveryjob,orevery50 hours,the shaft shouldbedisassembled,cleaned,

inspected, lubricated, andreassembled.

CAUTION:

lIfthe shaft beginstohelixexcessivelyduringoperation,stopand investigate.Thisis

an indicationofan overload condition.

lThe vibratorhead iscooled bytheconcrete.operation of the vibratorhead inairmore

than 2minuteswill causeoverheatingorthe bearingswhichresultinprematurehead

failure.

2.7WhenOperation isFinished

1Bringthe engine RPMdowntoidlespeed.

2Pull the vibratorhead outofthe concrete.

3Turnthe engine switchon the equipment tothe OFF position.

4Disconnect thevibratorshaft fromthe engine.

5ALWAYSrinseorwipeoffthe vibratorhead andshaft anywetconcretebeforeitdriesor

hardens.

7

MAINTENANCE

3MAINTENANCE

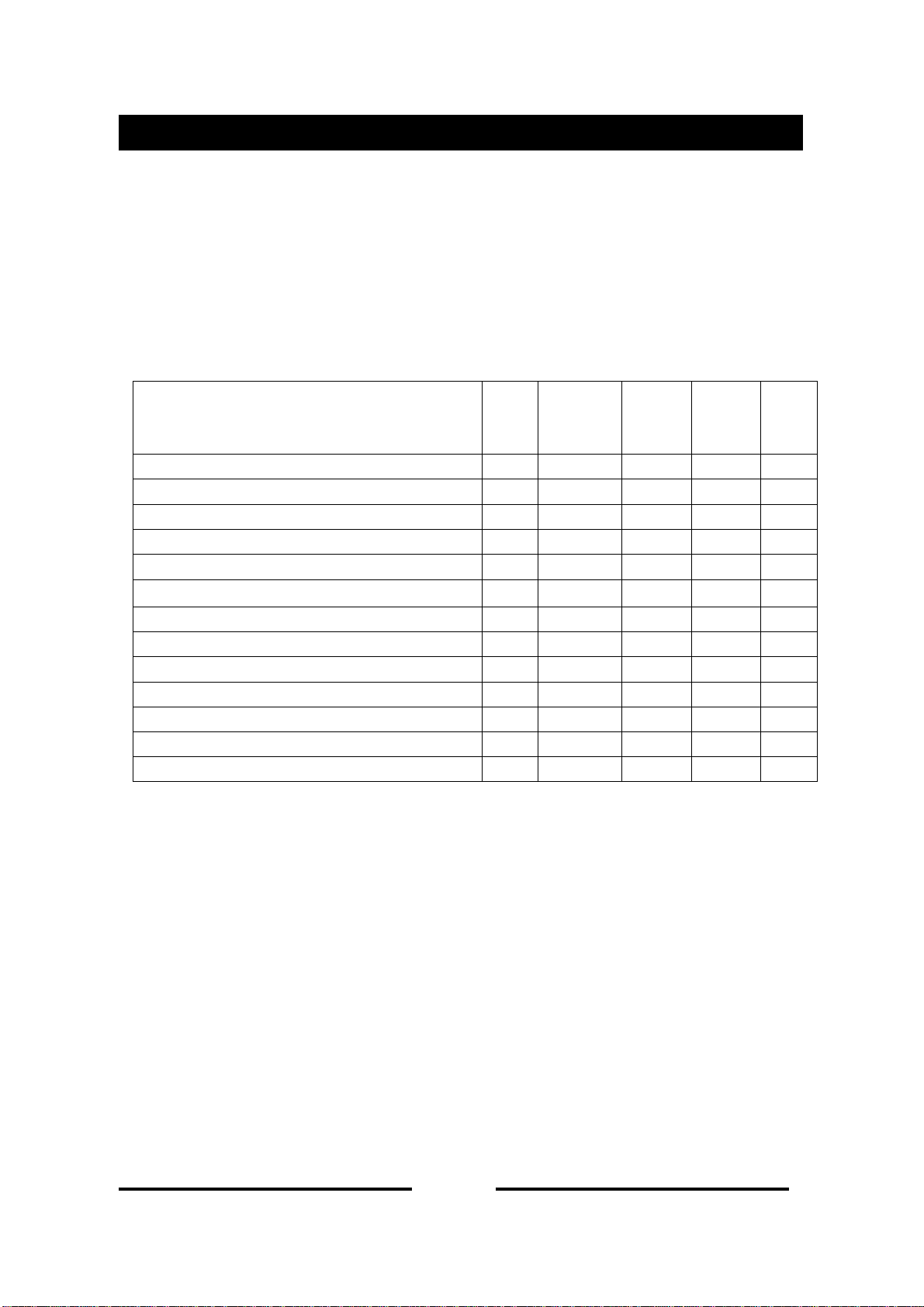

3.1PeriodicMaintenanceSchedule

Togetlonguseandfreeoftrouble,it isessentialtoperform periodicmaintenanceonthe

engineandmachine.AcopyoftheengineOperationManualwassuppliedwiththe

machine.

Daily

Afterfirst

10 hours

Every

25

hours

Every

100

hours

Ev

ery

300

hours

Check fuellevel. O

Check engineoil level. O

Inspectairfilter. Replaceasneeded. O

Check thatall boltedjointsaretightened. O

Check externalcomponents. O

Replacetheengine oil. O

Changeairfilter. O

Check andcleansparkplug. O

Check fuelfilter. O

Check fueltank. O

Cleanand lubricatetheflexibleshaft. O

Inspectand relubricatevibratorheads. O

Check andadjust valveclearance. O

3.2Lubrication

The longlifeand successfuloperationof anypartsofmachineryisdependenton

frequentandthoroughlubrication. Beforeusingthemachine,always checkthe oil and

useproperoil withthecorrect typeandgradeasrecommended.

NOTICE: DO NOTmixtypesofoil ingearboxandDO NOToverfill the oil. Damageto

themachinemayoccurifoilsaremixedoroverfilled.See TechnicalDataforoil quantity

andtype.

O

8

MAINTENANCE

3.3SparkPlug

Check andcleansparkplugsregularly.Afouled,dirtysparkplugmaycausehard

startingand poorengineperformance. Setsparkplug gaptorecommended clearance.

Refertoenginemanual.

The mufflerandenginecylinderbecomeveryhot duringoperationand

remainhot forawhileafterstopping theengine.Allowenginetocool

beforeremovingsparkplug.

NOTICE:Aloosesparkplug canbecomeveryhotandmaycauseenginedamage.

3.4AirCleaner

Maintainingacleanenginewill extendenginelife. Keepairfiltercleanatall times.

Cleanairfilterusing therecommendedsolventdaily. Seeenginemanualforproper

cleaningprocedure.Letthefilterdrybeforereinstalling.

NEVERusegasoline orothertypesoflowflashpoint solventsfor

cleaningtheaircleaner.Afireorexplosioncouldresult.

3.5Transporting

lALWAYSshutdownengine beforetransporting.

lTighten fueltankcapand closefuelcock toprevent fuelfromspilling.

3.6Storage

Forstoragethe machine forover30 days, the followingisrequired:

lChangeengine oil andseethedescription inengine manual.

lClean all externalpartsofthe engine andframewithasoft cloth.

lCoverthe machine and storeinaclean,dryarea.

!

WARNING

!

WARNING

9

MAINTENANCE

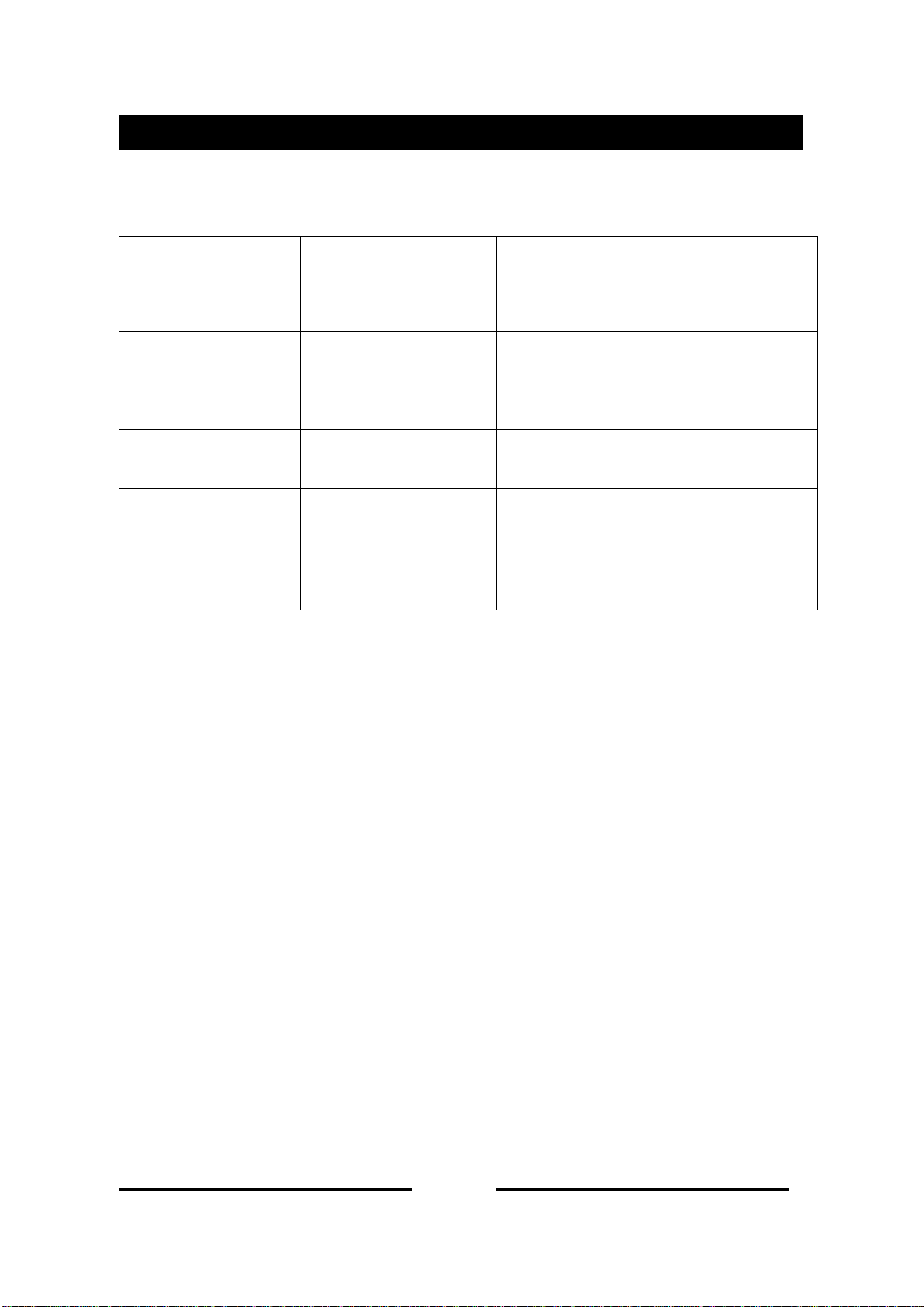

3.7Troubleshooting

SYMPTOM POSSIBLECAUSES SOLUTION

Flexibleshaft istoo

hottohold. Nolubrication? Greaseinnercore.

Vibratordoesnot

developfull speed. Engine? Depositsbuilt upinengine.

Check engineairfilter.

Throttleisdefectiveoroutof

adjustment.

Vibratingactionis

erratic. Headorflexibleshaft?

Clutch? Check headorflexibleshaft damage.

Check clutchwear.

Vibratorstops

shaking,continuesto

spinwithoutresuming

shaking action.

Metaldustmayhave

accumulated incontact

points?

Cleancontactpoints.

10

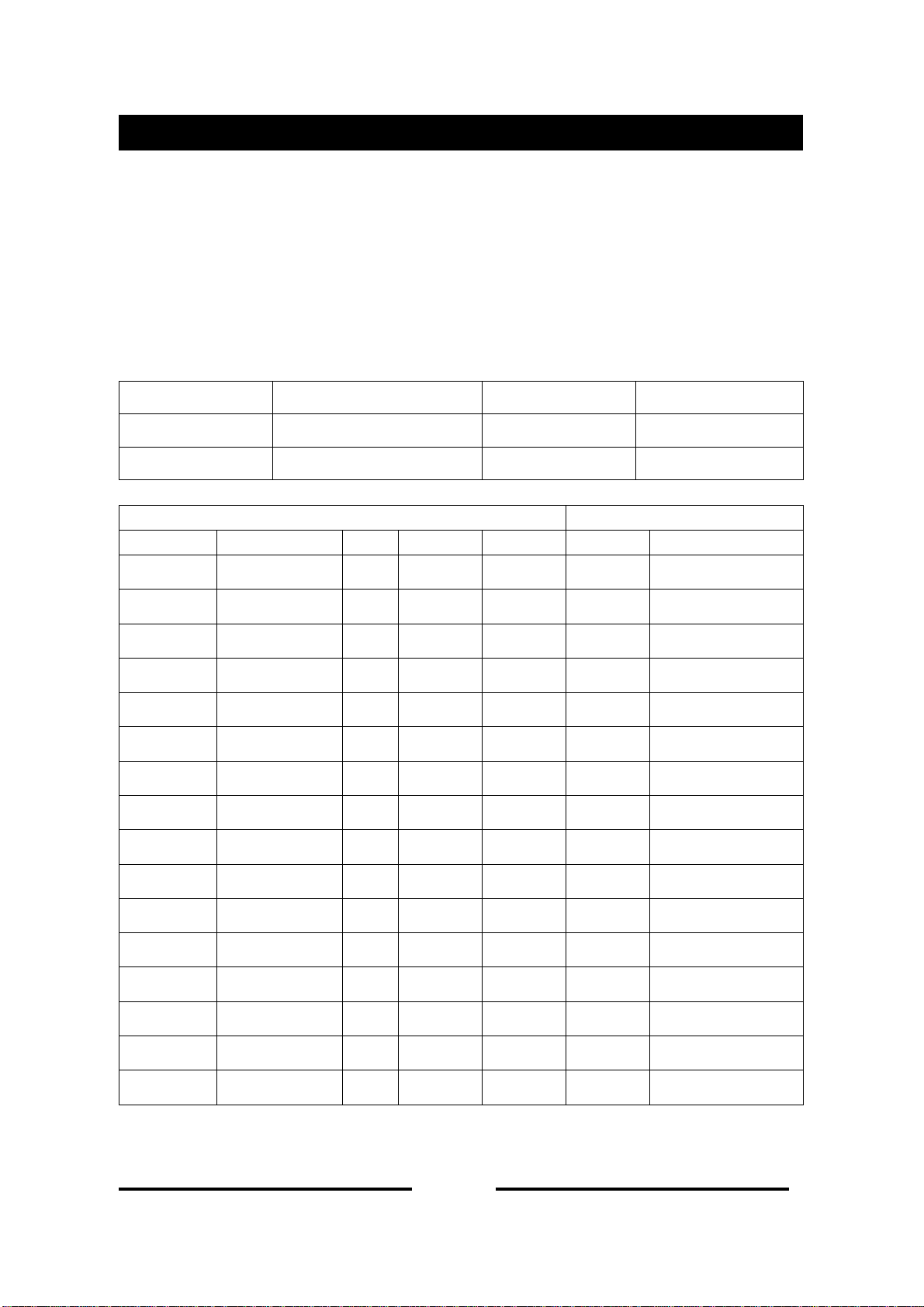

TECHNICALDATA

4.TECHNICALDATA

DriveUnit

ModelNo. Powerkw(hp)

MPG3215 1.2(1.6)

MPG3225 1.2(1.6)

MPG3815 1.2(1.6)

MPG3825 1.2(1.6)

VibratorHead

DiaxLength

(mm xm) VibratorAmplitude

mm Frequency

Hz RevolutionofFlexibleShaft

rpm

32 x1.5 1 225 3000-3600

32 x2.5 1 225 3000-3600

38 x1.5 1.2 225 3000-3600

38 x2.5 1.2 225 3000-3600

11

WARRANTY

5.WARRANTY

MASTERPACproductsarecovered bywarrantyforaperiodoftwelve(12)monthsfromthe

dateofpurchaseagainstdefectsinmaterialorworkmanshipprovided that:

lTheproductconcernedhasbeenoperated andmaintainedinaccordancewiththe

operatinginstructions.

lHasnotbeendamagedbyaccident,misuseorabuse.

lHasnotbeentamperedwithorrepairedbyanyunauthorizedperson.

The ownerisresponsibleforthe costoftransportationtoandfromthe authorized repairer

andthe unitisat theownersrisk whileintransit toandfromtherepairer.

Impactdamageisnotcoveredunderwarranty.Clutchesarenotcoveredunderany

warranty.

EnginesareofficiallyguaranteedbyHondamanufacturer.Pleaserefertotheannex

forenginewarranty.

12

MAINTENANCERECORD

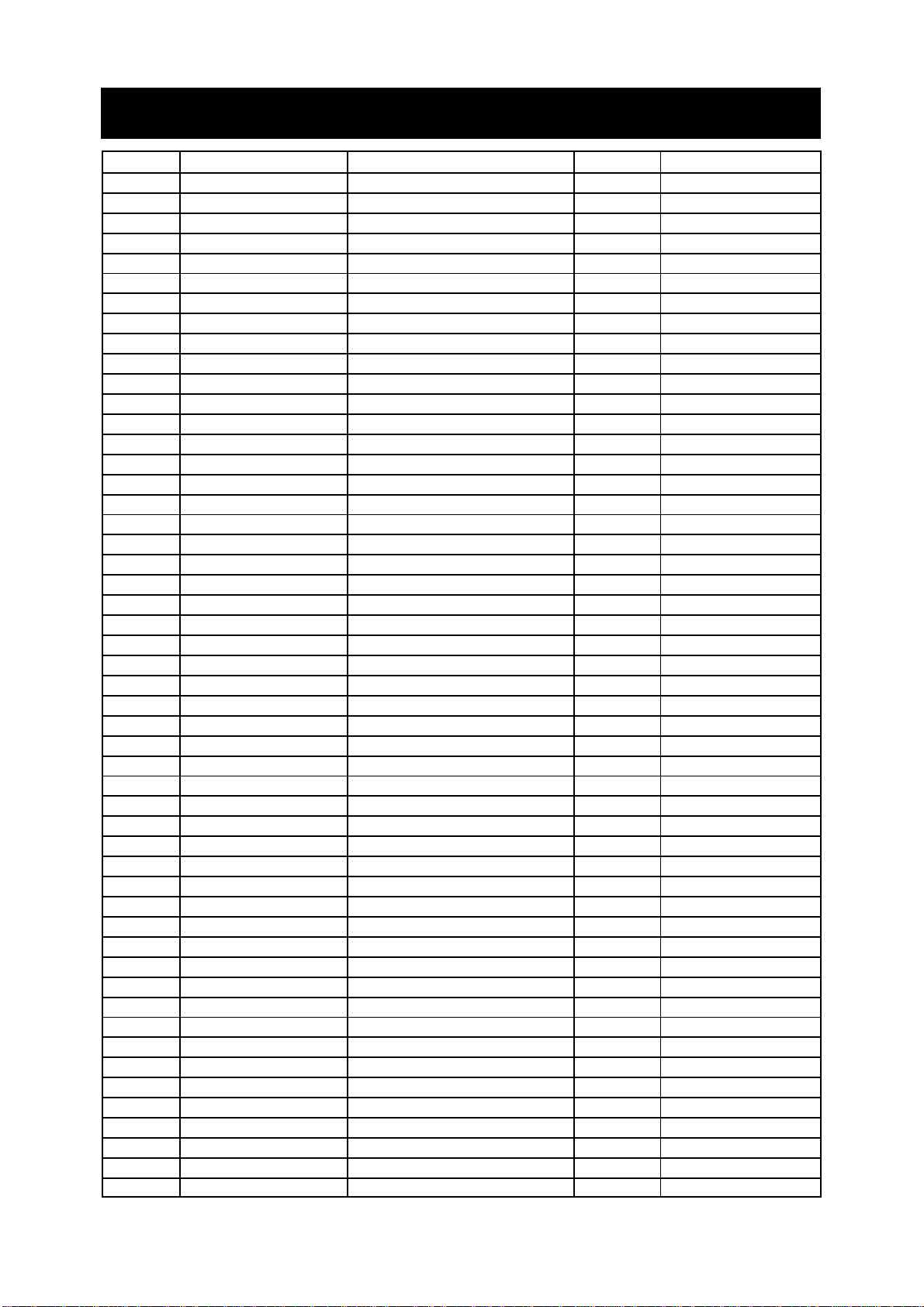

PREVENTATIVE MAINTENANCEAND ROUTINESERVICEPLAN

The machine hasbeenassembledwithcareand will provideyearsof service.Preventative

maintenanceandroutineserviceareessentialtothe longlifeofyourmachine.Afterreading

throughthismanualthoroughly,youwill findthat you candosomeoftheregular

maintenancebyyourself. However, wheninneedofpartsormajorservice,besuretosee

yourdealer. Foryourconveniencewehaveprovided thisspacetorecordrelevantdata

aboutyourmachine.

InvoiceNumber: Type of Machine:

DatePurchased: DealerName:

SerialNumber: DealerPhone:

REPLACEMENTPARTSUSED MAINTENANCELOG

PARTNO. DESCRIPTION

QTY COST DATE DATE OPERATION

MPG PORTABLE CONCRETE

VIBRATOR POKER DRIVE

PARTS LIST

RR

PARTSLIST

MPGSERIES

1

ITEM NO. PARTS NO. DESCRIPTION QTY REMARK

1GB/T5783 BOLT 8X20-8.8 1

2 GB/T859-M8 WASHER 8 1

3 GB/T96 WASHER 8 1

4 GB/T5783 BOLT M6X14-8.8 3

5 GB/T859-M6 WASHER 6 3

6BG431.1.1 SHOULDER FRAME COMP. 1

7GB/T276 BEARING 6002-2Z/P6 1

8 BG431.1-1 BEARING HOLDER 1

9GB/T6170 NUT M5 4

10 GB/T848 WASHER 5 8

11 BG520A.1A.1 WHIRLABOUT 1

12 BG431.3 CUSHION RUBBER COMP. 4

13 GB/T859-M5 WASHER 5 4

14 PBP.03.01 STAND 1

15 BG431.2 SHOULDER BELT ASSY 1

16 BG305.2.1 PIN 1

17 GB/T894.1 STOP RING 15 1

18 GB/T276 BEARING 6202-2RZ/P6 1

19 GB/T893.1 STOP RING 35 1

20 BG-328.8.1 CLUTCH DRUM COMP. 1

21 BG430.2.1-1 CLUTCH CASE 1

22 GB/T9074.13 SCREW M6X20 4

23 PBP.01.02-1 HOSE JOINT (32MM) 1 FOR MPG3215 MPG3225

PBP.01.02-2 HOSE JOINT (38MM) 1 FOR MPG3815 MPG3825

24 PBP.01.01-1 HOSE COUPLING (32MM) 1 FOR MPG3215 MPG3225

PBP.01.01-2 HOSE COUPLING (38MM) 1 FOR MPG3815 MPG3825

25 MPG.01.05-1 CONNECTOR(32MM) 1 FOR MPG3215 MPG3225

MPG.01.05-2 CONNECTOR(38MM) 1 FOR MPG3815 MPG3825

26 PBP.02.04-1 ECCENTRIC BEARING (32MM) 1 FOR MPG3215 MPG3225

PBP.02.04-2 ECCENTRIC BEARING (38MM) 1 FOR MPG3815 MPG3825

27 MPG.01.03-1 HOUSING(32MM) 1 FOR MPG3215 MPG3225

MPG.01.03-2 HOUSING(38MM) 1 FOR MPG3815 MPG3825

28 MPG.01.01-1 POINT (32MM) 1 FOR MPG3215 MPG3225

MPG.01.01-2 POINT (38MM) 1 FOR MPG3815 MPG3825

29 MPG.01.02 BEARING (NSK) 4

30 PBP.01.03-1 SHAFT JOINT (32MM) 1 FOR MPG3215 MPG3225

PBP.01.03-2 SHAFT JOINT (38MM) 1 FOR MPG3815 MPG3825

31 PBP.01.05.01-1 HOSE (32MM+1.5M) 1 FOR MPG3215

PBP.01.05.01-2 HOSE (32MM+2.5M) 1 FOR MPG3225

PBP.01.05.02-1 HOSE (38MM+1.5M) 1 FOR MPG3815

PBP.01.05.02-2 HOSE (38MM+2.5M) 1 FOR MPG3825

32 PBP.01.04.01-1 FLEXIBLE SHAFT(32MM+1.5M) 1 FOR MPG3215

PBP.01.04.01-2 FLEXIBLE SHAFT(32MM+2.5M) 1 FOR MPG3225

PBP.01.04.02-1 FLEXIBLE SHAFT(38MM+1.5M) 1 FOR MPG3815

PBP.01.04.02-2 FLEXIBLE SHAFT(38MM+2.5M) 1 FOR MPG3825

33 GB6170-M4 BOLT M4 2

34 GB97.1-4 NUT 1

35 PBP.03.02 ON OFF SWITCH 1

36 PBP.03.03 THROTTLE WIRE 1

37 PBP.03.04 THROTTLE LEVER 1

38 CHINESE 1.5HP PETROL ENGINE 1

PARTSLIST

MPGSERIES

2

This manual suits for next models

3

Table of contents

Other Masalta Power Tools manuals