9

4.Transporting the Machine

The machine will be delivered in a closed crate.

For transport use a forklift or hoist. Make sure

the machine does not tip or fall off during

transport.

Danger of tipping due to high gravity center!

During handling, the machine shall be lifted

only in vertical direction.

Please refer to instruction manual in

specification and machine weight to arrange

handling manner. Be sure to use capable fork -

lifter or hoist to lift of machine. The handling

and transportation shall be carried out by

qualified persons. Fork - lift or hoist can be

used in handling and shall be operated by

qualified driver.

Before handling, make sure all movable parts

are secured in their position and all movable

accessories should be removed from machine.

The steel rope should average pull the machine

head, table and column tightly.

Keep all the processes in a carefully and slightly

condition. Bump or crash are strictly

prohibited. It will cause precision shift and

electronic controller damaged.

5.Machine Installation

5.1. Positioning the Machine

I. The head and the worktable of the machine

can be rotated 360, so choose a location

with enough space and solid foundation.

II. Clean all rust protected surfaces with a mild

solvent e.g. petroleum.

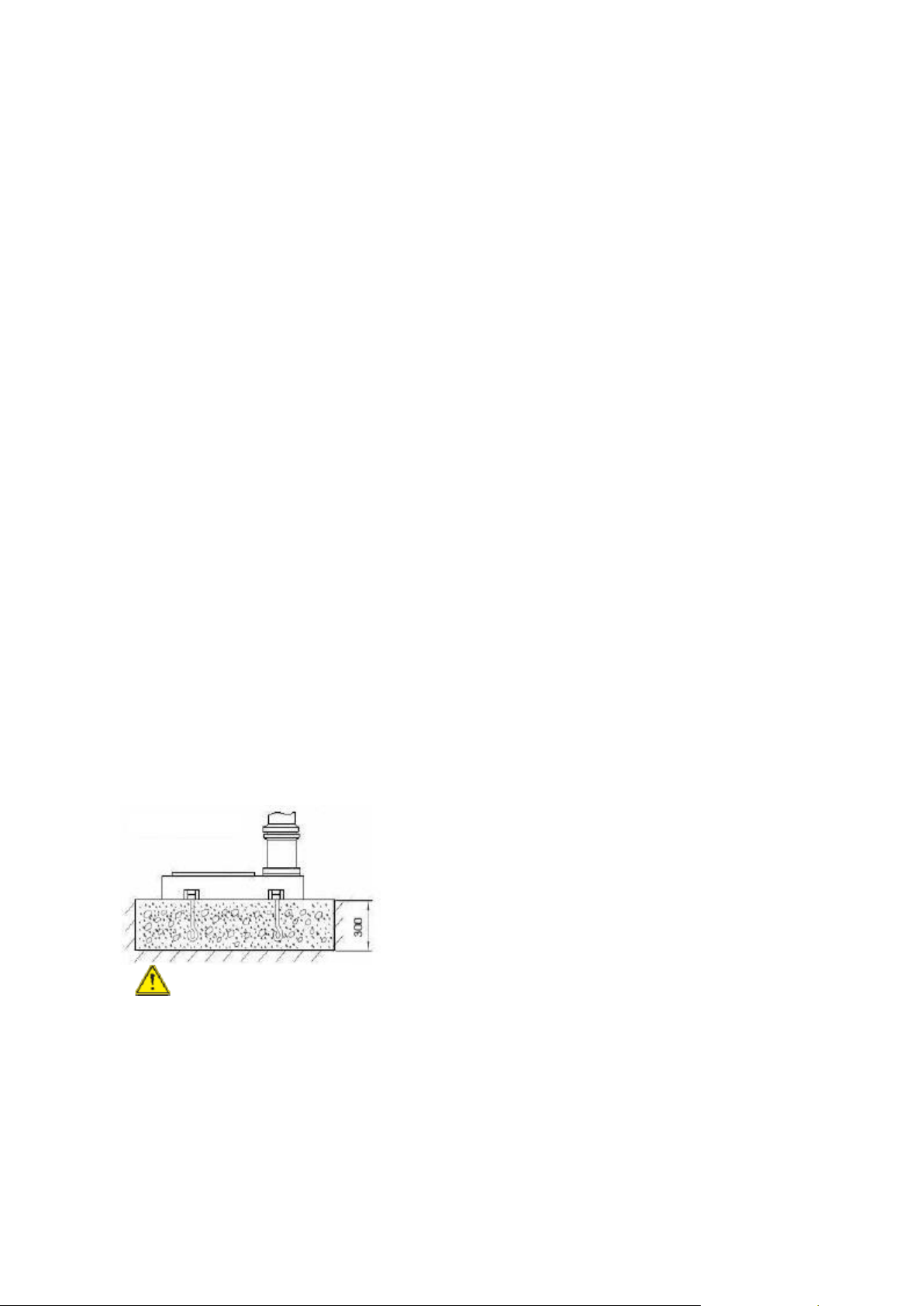

5.2. Anchoring the Machine

Assure the sufficient load capacity and

proper condition of your lifting devices.

I. Position the machine on a firm and level

concrete floor.

II. A minimum distance of 800mm towards a

rear wall must be kept (for access to the

electrical box).

III. Anchor the machine to the ground, as

shown in the diagram, using screws and

expansion plugs or sunken tie rods that

connect through holes in the base.

5.3. Minimum Requirement for

Housing the Machine

Please comply with the following terms to

maximize the life and performance of the

machine and its components.

The Main voltage and frequency complying

with the requirements for the machine's

motor.

Environment temperature from -10°C to

+50°C.

Relative humidity not over 90%.

5.4. Assembling Loose Parts

Attach Riser handle to the necessary

crankshaft, and use Hex-wrench to

tighten/loosen the machine head lock nut.

5.5. Electrical Connection of the

Machine

Make sure whether the voltage 400V

matches the requirement for the machine,

prior to connection to power supply. If the

machine cannot be operated after wires

have been connected, please check the

following items:

I. Is the Emergency switch released?

II. Is the door of the electrical cabinet is

properly closed and switched ON

(locked) position?

III. Is the safety guard in the proper

position (closed)?

5.6. Coolant

Before operating a new machine, please

add coolant to the coolant tank, fill the

coolant to at least half (minimum 6 liters).

User can choose the one most suitable for

their requirements. For your reference

SHELL LUTEM OIL ECO is highly

recommended. The ratio of oil and water is

50% respectively. The minimum percentage

of oil diluted in water is 8~10%. Cleaning is

required when iron filings clog the screen

(Fig.4) at the bottom right corner of the

water drain entry at the base.