Masalta ML42 User manual

WARNING

!

R

INSTRUCTION MANUAL

LIGHT TOWER

ML42/ML44

1

Table of Contents

1. SAFETY INFORMATION………………………………………………………….…………………………………2

1.1 Safety Precautions ……………………………………………………………………………………….……………2

1.2 Operating Safety…………………………………………………………………………………………………………3

1.3 Operator Safety while using Internal Combustion Engines…………………………………5

1.4 abel locations……………………………………………………………………..………………………….………6

1.5 Safety and Operating abels……………………………………………………………………….…………7

1.6 Service Safety……………………………………………………………………………………………….…………9

2. OPERATION…………………………………………………………………………………………………………………10

2.1 Preparing the Machine for First Use…………………………………………………..……………………10

2.2 ocating ight Tower …………………………………………………………………………………………………10

2.3 eveling Machine ……………………………………………………………………………………..……….………11

2.3.1 Operation of the outriggers…………………………………………………………………..……….………11

2.3.2 Operation of brake …………………………………….………………………………………………..…………12

2.4 Install the light…………………………………………….………………………………………………………………13

2.5 Adjusting the lighting angle…………………………………….…………………………………………………15

2.6 Control Panel …………………………………………………………………….………………………………………16

2.7 Raising the Tower (Manual Winch) ………………………………….………………………………..……16

2.8 owering the Tower (Manual Winch) ……………………………….…………………………………..…17

2.9 Manually Starting the Machine………………………………………….……………..………………………17

2.10 Stopping the Machine……………………………………………………….…………….…………….…………18

2.11 Restart the light on…………………………………………………………….…………….………………………18

2.12 Transportation………………………………………………………………..….….…………………………………18

2.13 Storage………………………………………………………………………………….………….………………………19

3. MAITENANCE………………………………………………………………………….………….………………………20

3.1 Periodic Maintenance Schedule ………………………………………….………….………………………20

3.2 Installing / Removing ight Fixtures ……….…………………………….…………………………………21

3.3 Replacing / Removing amps ………………….…………………………….………..………………………21

3.4 Checking Engine Coolant………………………….…………………………...………..………………………22

3.5 Cleaning Air Filter Element………………………….………………………...…………………………………22

3.6 Changing Engine Oil……………………………………………………………….………..………………………23

3.7 Maintaining the Fuel/Water Separator………….………………………….………………………………23

3.8 Troubleshooting……………………………………………………………..………….….…..………………………25

4. TECHNICAL DATA ……………………………………………………………………….……………………………26

. WARRANTY …………………………………………………………………………………..……………………………27

6 MAINTENANCE RECORD ………….………………………………………………….………………….………28

7 EC DECLARATION ………….………………………………………………………………..……………………….29

2

1.

SAFETY INFORMATION

1.1 Safety Precautions

Before operating the machine, read both the manual and the engine manual

carefully to become familiar with the location and proper use of all controls. Do not

allow untrained or unauthorized personnel, especially children, to operate this

machine. Use only the parts authorized by the factory for service.

This manual contains DANGER, WARNING, CAUTION callouts which must be

followed to reduce the possibility of personal injury, damage to the equipment, or

improper service.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible injury

or death.

DANGER indicates a hazardous procedure which, if not

avoided, will result in serious or mortal injury.

WARNING indicates a danger or hazardous procedure

which, if not avoided, could result in serious or mortal

injury.

CAUTION indicates a danger or hazardous procedure

which, if not avoided, could result in damage to

machinery or moderate injury.

CAUTION

DANGER

SAFETY INFORMATION

3

1.2 Operating Safety

Before operating the machine:

Operator training

Read and understand the operating instructions contained in all manuals

delivered with the machine.

Familiarize yourself with the location and proper use of all controls and safety

devices.

Contact Masalta Corporation for additional training if necessary.

When operating this machine:

Do not allow improperly trained people to operate the machine. People

operating the machine must be familiar with the potential risks and hazards

associated with it.

Personal Protective Equipment (PPE)

Wear the following Personal Protective Equipment (PPE) while operating this

machine:

Close-fitting work clothes that do not hinder movement

Safety glasses with side shields

Hearing protection

Safety-toed footwear

Work area

Make sure the area immediately surrounding the ight Tower is clean, neat,

and free of debris.

The tower extends up to 3.7m/5.0m (M 42/M 44). Make sure the area above

the trailer is open and clear of overhead wires and obstructions.

Machine setup

Make sure the machine is on a firm, level surface and will not tip, roll, slide, or

fall while operating.

Make sure the machine is well-grounded and securely fastened to a good

earthen ground per national and local regulations.

The trailer must be leveled and the outriggers extended before raising the

tower.

The outriggers must be extended while the tower is up.

Never connect the machine to other power sources, such as supply mains of

power companies.

Machine integrity

Do not start a machine in need of repair.

Do not use the machine if the insulation on any electrical cord is cut or worn

through.

Do not operate the lights without the protective lens cover in place or with a

lens cover that is cracked or damaged.

Replace or repair electrical components with components that are identical in

rating and performance to the originals.

While operating the machine

SAFETY INFORMATION

4

Keep the area behind the trailer clear of people and obstructions while raising

and lowering the tower.

Do not raise the tower or operate the machine in high winds. ower the tower

immediately if high winds or electrical storms are expected in the area.

Do not raise, lower, or turn the tower while the unit is operating.

If any part of the tower hangs up, or the winch cable develops slack while

raising or lowering the tower, STOP immediately! Contact an authorized

Masalta service representative.

Do not disengage the tower locking pin while the tower is up.

amps become extremely hot in use! Allow the lamps and fixtures to cool

10–15 minutes before handling.

ower the tower when not in use.

SAFETY INFORMATION

DANGER

DANGER

When the strong wind shakes the machine, lower the tower.

The strong wind means the speed more than 10m/s

DANGER

DANGER

Make sure the machine is on a firm, level surface and will not tip,

roll, slide, or fall while operating.

Gradient<5

°

Turn the wheel away from the curb if the car is facing uphill.

The back of the front tire should be turned into the curb.

DANGER

DANGER

Connect the grounding wire before using.

5

1.3 Operator Safety while using Internal Combustion Engines

DO NOT smoke when refueling the engine or operating the machine.

DO NOT refuel a hot or running engine.

A WAYS keep away from all hot or spark-generating objects when

refuel the engine.

A WAYS refill the fuel tank until the machine has cooled, and in a

well-ventilated environments.

DO NOT spill fuel when refueling the engine.

A WAYS take care to use the right type of fuel.

A WAYS inspect the fuel leakage regularly.

NEVER perform any work on the machine while it is running. Before

working on it, stop the engine and disconnect the spark plug wire to

prevent accidental starting.

Avoid prolonged breathing of exhaust gases.

A WAYS transport and handle fuel only when contained in approved

safety containers.

Avoid touch or lean against hot exhaust pipes.

Allow engine to cool before performing any repairs or service.

A WAYS keep the area around the muffler free of debris such as

leaves, paper, cartons, etc. A hot muffler could ignite the debris and

start a fire.

NEVER run the engine without air filter.

SAFETY INFORMATION

6

1.4 Label locations

SAFETY INFORMATION

7

1. Safety and Operating Labels

Label Meaning

DANGER!

Engines emit carbon monoxide; operate

only in well-ventilated area. Read the

Operation Manual for machine

information. No sparks, flames, or

burning objects near the machine. Shut

off the engine before refueling. Use only

clean, filtered unleaded gasoline.

WARNING!

Read and understand the supplied

Operation Manual before operating the

machine. Failure to do so increase the

risk of injury to yourself or others.

WARNING!

Always wear hearing and eye protection

when operating the machine.

NOTICE!

Check the tire pressure before using

everytime.

CAUTION!

To avoid the tower rollover, please lower the

mast when moving, lifting or transporting the

machine.

WARNING!

Hot surface!

Label Meaning

SAFETY INFORMATION

8

CAUTION!

Cut off the power before disconnecting light

fixtures or changing lamps.

DANGER!

Do not touch the terminals if your clothing or

skin is wet!

CAUTION!

Secure in transport lock before lifting or

lowing. Be careful when you adjust the light.

CAUTION!

Do not run the machine indoors or in an

closed area.

The specification of Ballast.

WARNING!

Read and understand the supplied

Operation Manual before operating the

machine. Failure to do so increase the risk of

injury to yourself or others.

CAUTION!

Operate outrigger as the instruction.

CAUTION!

Close the rain cover in rainy weather.

9

1.6 Service Safety

Precautions

To reduce the risk of personal injury, read and understand the service

procedures before performing any service to the machine.

All adjustments and repairs MUST be completed before operation. Do not

operate the machine with a known problem or deficiency! All repairs and

adjustments should be completed by a qualified technician.

Do not service the machine if your clothing or skin is wet.

Personal Protective Equipment (PPE)

Wear the following Personal Protective Equipment (PPE) while servicing or

maintaining this machine:

Close-fitting work clothes that do not hinder movement

Safety glasses with side shields

Hearing protection

Safety-toed footwear

In addition, before servicing or maintaining the machine:

Tie back long hair.

Remove all jewelry (including rings).

Before servicing the machine

Turn the engine off before performing maintenance or making repairs.

Make sure the engine start switch is turned to OFF.

Make sure the circuit breakers are open (off).

Make sure the negative terminal on the battery is disconnected.

Do not perform even routine service (oil / oil filter changes, cleaning, etc.)

unless all electrical components are shut down.

Make sure water has not accumulated around the base of the machine. If

water is present, move the machine and allow it to dry before servicing.

If the machine must be started while servicing, keep hands, feet, and loose

clothing away from moving parts on the generator and engine.

Safety devices and modifications

Replace all safety devices and guards after repair and maintenance.

Do not modify the machine without the express written approval of the

manufacturer.

Replacing parts and labels

Replace worn or damaged components.

Use only spare parts recommended by Masalta.

Replace all missing and hard-to-read labels.

WARNING

High voltage! This machine produces high voltage capable of causing

serious injury or death.

Only a qualified electrician should troubleshoot or repair electrical

problems occurring with this machine.

SAFETY INFORMATION

10

Check all external fasteners at regular intervals.

2.1 Preparing the Machine for First Use

To prepare your machine for first use:

1. Make sure all loose packaging materials have been removed from the machine.

2. Check the machine and its components for damage. If there is visible damage,

do not operate the machine! Contact your Masalta dealer immediately

for assistance.

3. Take inventory of all items included with the machine and verify that all loose

components and fasteners are accounted for.

4. Attach component parts not already attached.

5. Add fluids as needed and applicable, including fuel, engine oil, and battery acid.

6. Move the machine to its operating location.

2.2 Locating Light Tower

Positioning

the machine

WARNING

Electric shock or equipment damage hazards.

The tower extends up to 3.7m/5.0m (M 42/M 44). and

could interfere with overhead wires and obstructions.

Position the machine on a firm, flat surface clear of

overhead wires and obstructions.

Make sure that there is enough area for outrigger

extensions to be fully extended.

Ground

Connection

Function

For maximum light coverage, locate the ight Tower at ground level

or in a spot higher than the area being lighted.

A ground connection is located on the machine

frame.

The ground connection is used for electrically grounding the ight Tower when

necessary to comply with the National Electrical Code and other federal, state,

and local regulations. For grounding requirements in your area, consult with a

qualified electrician, electrical inspector, or local agency having jurisdiction

over electrical compliance.

If the ight Tower is used at a construction site, there may be additional

regulations which must be observed.

OPERA

TION

11

2.3 Leveling Machine

evel the machine and extend the outriggers before raising the tower. The

outriggers must remain extended while the tower is up, and keep the machine

braked.

2.3.1 Operation of the outriggers

Put down the outriggers, the outriggers will be locked automatically

When the outriggers can not be turned smoothly, please depress the lock as

indicating arrow.

WARNING

Tipping / falling hazard. Failures to level the machine or extend

the outriggers will severlyreduce the stability of the unit.

OPERATION

Storing

Using

WARNING

If the generator is not fixed on when it is windy, you must put

down the outriggers.

Outriggers

12

When you store the outriggers, please depress the lock as indicating arrow.

Press the lock and turn the outriggers on the baseplate of machine.

2.3.2 Operation of brake

Presses the brake pedal, and then pull back the pedal.

Brake

Brake

OPERATION

13

Release the brake

2.4 Install the light

Procedure

1. Turn the lamp inside the lamp holder.

Warning Do not turn the lamp overly, it may cause to damage to the

lamp.

2. Inset the lamp holder to the retroreflector.

amp

amp holder

amp holder

Retroreflector

Release

WARNING

Turn the wheel away from the curb if the car is facing

uphill. The back of the front tire should be turned into

the curb.

OPERATION

14

3. Tighten the fasteners, fix the lamp holder and retroreflector

4. Fix the light on the light holder but leaving the light is possible to be adjusted

for the suitable lighting angle.

5. Remove the cover of terminal box

6. Fix the wire as the picture showing

7. Connect the wire end into the socket

8. Cover the terminal box

2. Adjusting the lighting angle

OPERATION

OPERATION

Fasteners

Washer

Spring washer

Nut

Terminal box

Upper light

Downside light

Cable

15

Raise the light holder

eft and right

Adjust the lamp holder

Adjust the lamp holder between the angle inside the range

as following:

1000W Up: <15 degree Down: <90 degree

400W Up: <15 degree Down: <75 degree

Hold the light holder and loose the lock.

Raise the light holder, pull the drop handle down,

fixed the light holder

Turn the lighting angle of all the lights

Release the reorientation latch, turn the light

holder, fix the light holder.

16

Notice: Turn the screw completely to fix the lamp hold after getting the suitable

lighting angle.

2.6 Control Panel

2.7 Raising the Tower (Manual Winch)

Continue rotating the winch handle clockwise until the tower is at the desired

height. Do not overcrank the winch when the tower is fully extended.

Up and down

OPERATION

17

2.8 Lowering the Tower (Manual Winch)

Continue rotating the winch handle counterclockwise until the tower is

resting the bottom.

2.9 Manually Starting the Machine

Prerequisites

Engine oil, fuel, and coolant are at the proper levels

Note: If fuel tank was drained or run dry it may be necessary to bleed fuel lines.

Refer to engine operator’s manual.

Electrical cable on the tower is in serviceable condition

Circuit breakers are in their OFF positions

Procedure NOTICE: Starting the engine under load will damage the

machine.

Follow the procedure below to manually start the machine.

1. Press the START switch. This initiates the pre-heat timer,

energizes the fuel

solenoid, and energizes the starter motor.

2. The engine will crank for 10 seconds, and then rest for 10

seconds. If the engine

does not start immediately, the cycle will repeat three (3) times.

3. If the engine does not start after three attempts, the starting

sequence will be

terminated and the Overcrank shutdown indicator will light. See

section

Troubleshooting Automatic Shutdown for help.

4. When the engine starts, the starter motor is disengaged.

Note: After the starter motor has disengaged, the Safety On

WARNING

Electric shock hazard. Do not start the generator if the insulation

on the tower electrical cable is cut or worng through.

OPERATION

18

Timer is acti ated.This timer is pre-set for a 12 second delay and

allows oil pressure, high engine temperature, underspeed, and

charge failure to stabilize without triggering the fault.

5. If a fault occurs after the 12 second delay, see section

Troubleshooting Automatic Shutdown. 5. If a fault occurs after the

12 second delay, see section Troubleshooting Automatic

Shutdown.

6. Allow engine to warm up 3mins before operating lights.

7. Turn the light switch in the “ON” position

NOTICE: Do not use starting fluids to aid in starting of engine.

2.10 Stopping the Machine

Prerequisite ights are turned off.

NOTICE: Generator will be damaged if the engine is shut down before turning off

the lights.

Stopping the machine Push the OFF button to de-energize the fuel solenoid.

2.11 Restart the light on (Once the lights are turned off, you can not turn on the

lights immediately)

Make sure the light switch is in the OFF position.

Cooling the light for 20-30mins

Return the light as the order : Start the generator→turn on the power switch→turn

on the light switch

2.12 Transportation

Prerequisites

Make sure the switch of generator and light are in the OFF position.

ower the tower down

OPERATION

Notice

The direction of front wheel is opposite with the

direction of steering handle.

WARNING

Block the machine and fixed completely by

rope when transports the machine by car.

19

2.13 Storage

Turn the light to forward

Hold the light holder and

loose the lock

Press down the light holder

ock the light holder by fixed handle after press

down completely.

NOTICE Do not store the light holder vertically

OPERATION

This manual suits for next models

7

Table of contents

Popular Work Light manuals by other brands

Party Light & Sound

Party Light & Sound PAR181 user manual

Good Earth Lighting

Good Earth Lighting RE1174-WHG-08LF4 quick start guide

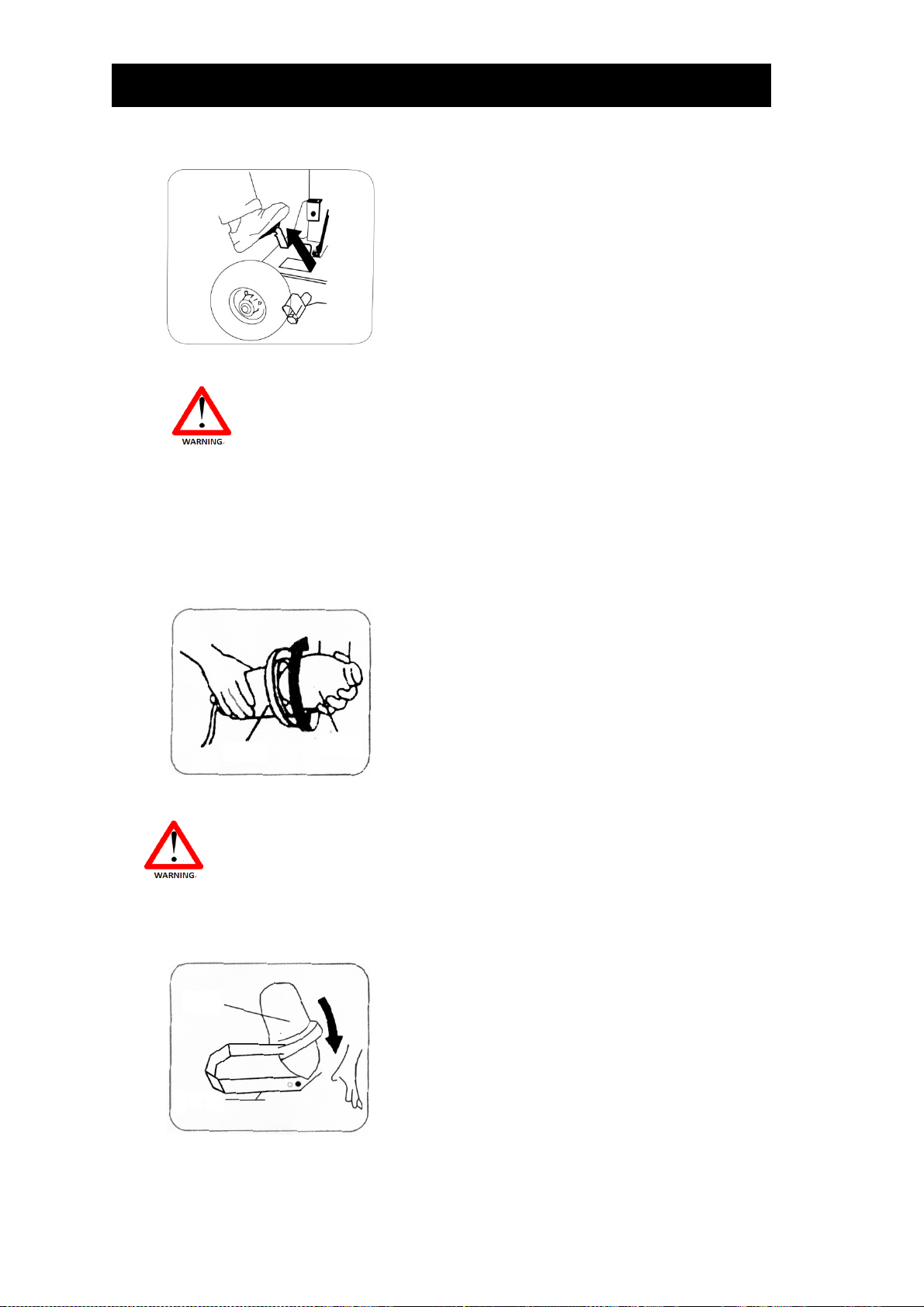

jcb

jcb JCB-SL-TUFFDUAL Instruction and user's manual

Clore Automotive

Clore Automotive Light-N-Carry LNCPOD Operator's manual

Clarke

Clarke SMD42T Assembly & user instructions

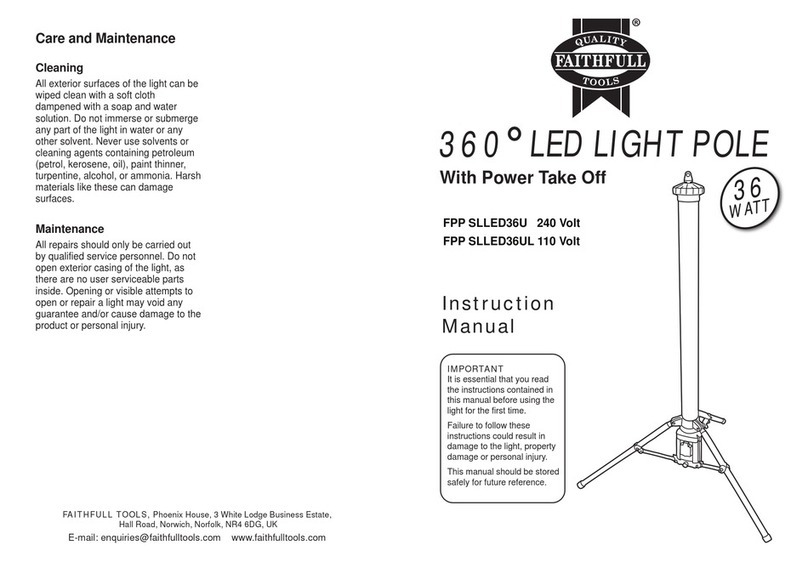

Faithfull

Faithfull FPP SLLED36U instruction manual