5

P/N 450077 7/12

5

REQUIREMENTS FOR SUCCESSFUL INSTALLATION

CAUTION: DO NOT use drywall screws during installation. Product damage will occur and void the warranty.

CAUTION: The entire bottom support must be in contact with a fl at, level surface.

CAUTION: Handle glass with care. Tempered glass may break if the corners are hit against hard surface.

◘Read complete instructions before beginning installation.

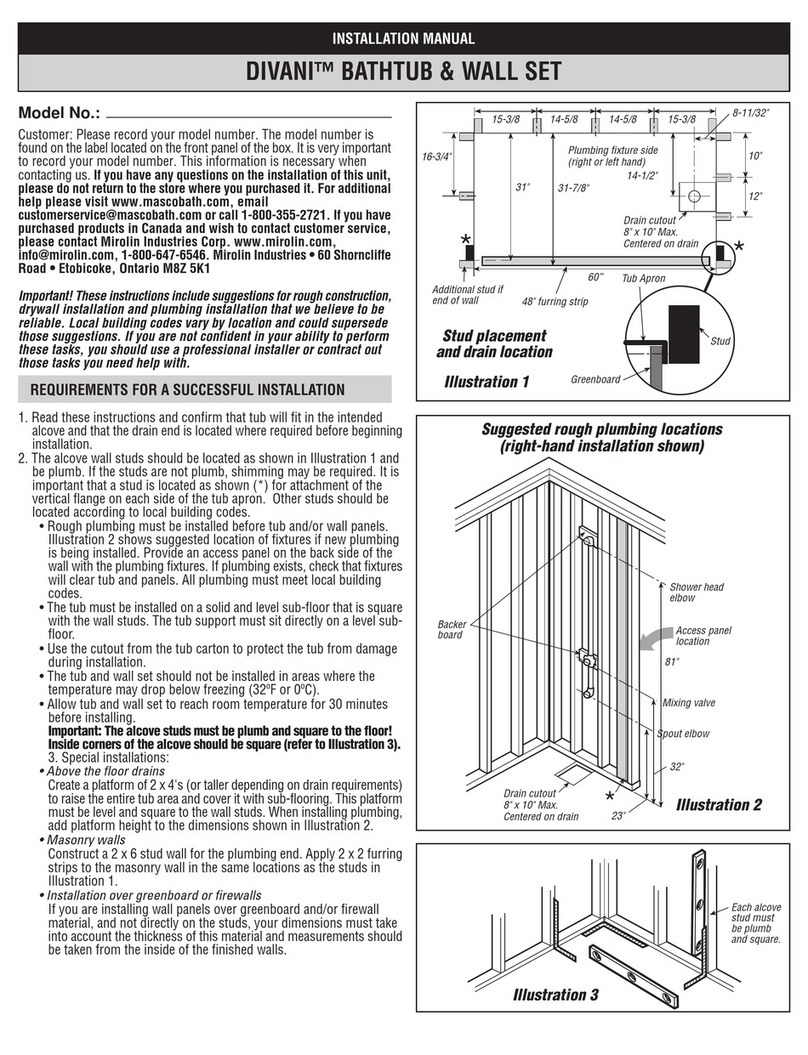

◘These instructions include suggestions for rough construction and plumbing installation that we believe to be reliable.

Local building codes vary and could supersede those suggestions. If you are not confident in your ability to perform

these tasks, contract out those tasks you need help with or use a professional installer.

◘Confirm that your model will fit in intended location and plumbing fixtures are located where required before beginning

installation.

◘Walls must be solid, plumb and square. This shower kit has been designed with some adjustability for minor alignment

problems, but a poor foundation will result in a poor installation.

◘If installation surface is not level, use leveling compound or mortar bed for proper installation.

◘Use drop cloth to protect base from damage during installation.

◘Do not install in areas where temperature may drop below 32ºF (0ºC).

◘Allow product to reach room temperature for 30 minutes before installation.

◘Two people recommended to install this product.

TOOLS AND MATERIALS REQUIRED

Square

Pencil Safety glasses

Drill

Drill bits

3/32"

1/8"

3/16"

Tape measure

1-1/4" screws

(zinc or stainless;

panhead or

roundhead) (8 for

base; 16 for wall set)

Shims

(wall set and

base only)

Adhesive

(2 tubes)

Hole saw

(sized to

accommodate

plumbing fixtures,

wall set only)

Sealant

(1 tube)

Drop cloth

#2 Phillips

screwdriver

(enclosure only)

Masking or

painters’ tape

(enclosure only)

1/4" v-notched

trowel

(base only)

Utility knife Adjustable wrench

(wall set only)

Extension bit

holder

(base and

enclosure only)

Caulk gun

Level

#2 Phillips bit

(for use with

extension bit holder,

base and enclosure only)

◘2" x 4" lumber for additional wall studs

Lumber for bracing

Water and drain line materials and fittings

Rags or padding to protect product during bracing

TIP: You may want to install insulation.