VFlo Control Valves

2

GENERAL INFORMATION

The instructions presented below are for helping in un-packing,

installing and performing maintenance as and when needed on

Mascot VFlo ball valves. The manual should be thoroughly

reviewed by Product users and maintenance personnel before

performing any operation on the valve. Separate maintenance

instructions cover additional features (such as actuators, special

accessories, fail-safe systems, etc.).

For information on Mascot positioners, refer to the appropriate

Mascot Installation, Operation and Maintenance instructions.

Please follow the procedures laid down to avoid possible injury

to personnel or damage to valve parts. Any modification in this

product, or using non-factory or inferior parts, employing

maintenance procedures other than prescribed can affect

performance adversely; moreover, it can be dangerous to

personnel and equipment, and also void existing warranties.

WARNING : It is mandatory to follow standard industry safety

practices. Personal protective and lifting devices must be used

as specified.

Note : The onus of choosing the proper fastener material lies on

the customer. The supplier cannot know what the valve service

conditions or environment might exist. The standard body bolting

material for Mascot's is B7/2H. For applications above 800° F

and with stainless steel or alloy body valves B8 (stainless steel) is

optional. It is up to the customer therefore to consider the

material's resistance to general corrosion and stress corrosion

cracking. Every mechanical equipment needs periodic inspection

and maintenance. The details on fastener materials can be

obtained from your local Mascot representative or factory.

Unpacking

First step is to check packing list against the materials

received during the unpacking of the valve. Each shipping

container has lists describing the valve and accessories.

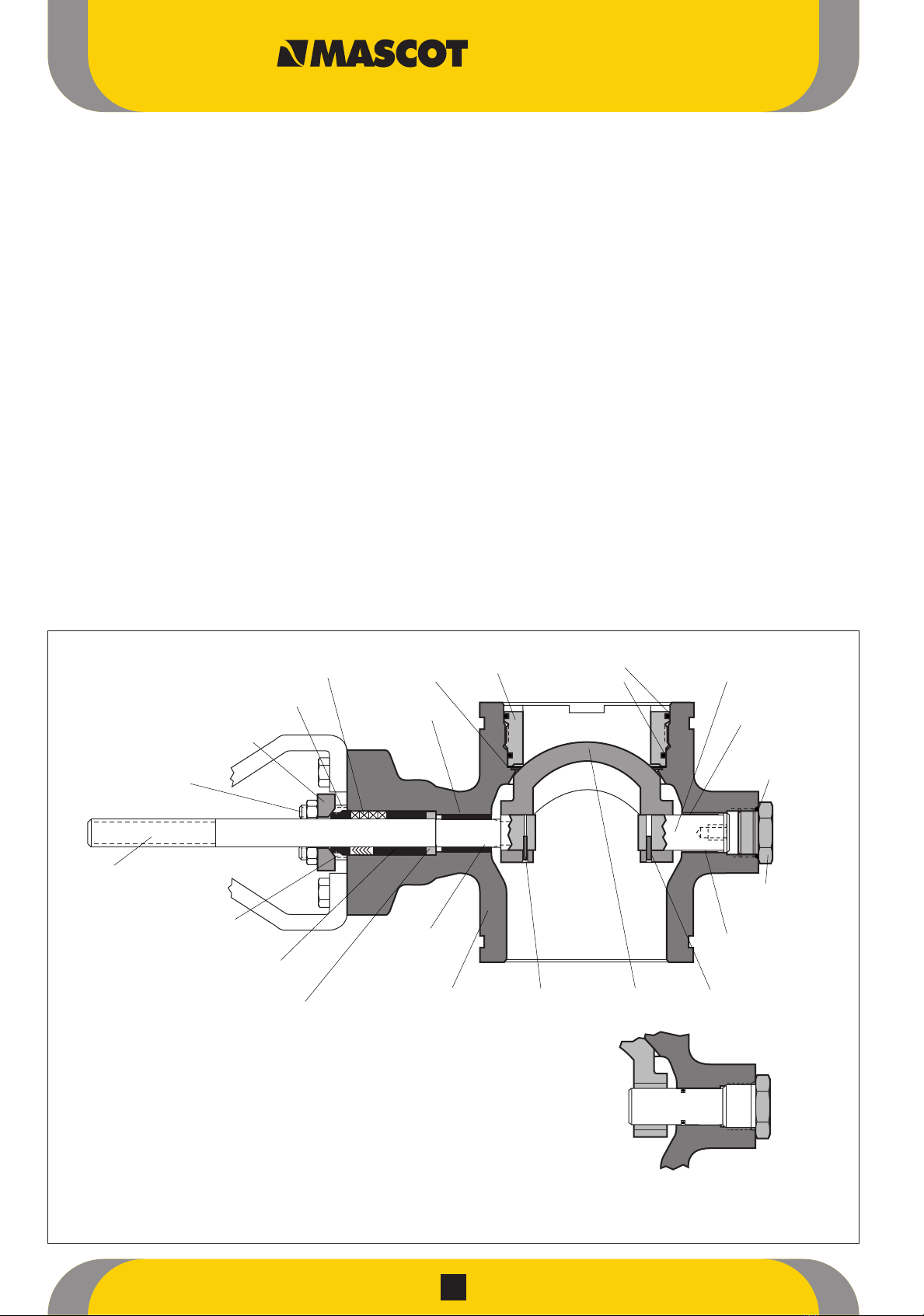

For lifting the valve from the shipping container, lifting straps

need to be positioned to avoid damage to tubing and

mounted accessories. Where valves are provided with a lifting

ring, please use the same for lifting. Valves up through 8-inch

may be lifted by the actuator lifting ring. Larger valves can be

lifted using lifting straps or hook through the yoke legs and

outer end of the body.

WARNING : During lifting of a valve with lifting straps

through the yoke legs, one must have in mind that the

center of gravity may be above the lifting point and

support must be given to prevent the valve from rotating.

Serious injury to personnel or damage to nearby

equipment can take place if proper attention is not paid to

this factor.

On observation of damage in transit, shipper should be

contacted immediately.

The Mascot representative is always at your service whenever

needed.

Quick-Check

Before beginning, check the control valve as per the steps

mentioned below:

By making the appropriate instrument signal change, verify

for full stroke. The position indicator plate is mounted on the

actuator transfer case for observation. Position of the

indicator plate should change in a smooth, rotary fashion.

CAUTION : The full torque load of the actuator cannot be

taken by the VFlo valve shaft. The shaft could twist and/or

shear if the ball were to seize and full torque continued.

There should be no leaks in the air connections. Any leaky

lines should be repaired by tightening or replacement.

Tighten of the packing nuts is to be done to slightly over

finger-tight and evenly.

CAUTION : Over tightening of packing nuts can cause

excessive packing wear and high shaft friction and shaft

rotation will be adversely affacted. Every short time valve

has been in operation, check the packing nuts to ensure

they are torqued properly. Do correction if necessary. Any

leaking in the packing box should be corrected by

tightening the packing nuts. The tightening should be only

enough to stop leakage.

In case of air failure, for observing the valve failure mode,

position the valve to mid-stroke and shut off the air supply to

the actuator or disconnect the instrument signal to the

positioner. The actuator indicator plate should move to either

fail/open or closed position. If not, the "Reversing the

Actuator Action" section in the actuator maintenance

instructions needs to be referred.

*Torque values are recommended for low and intermediate

strength bolting per ANSI B16.5 5.3.2. Higher torques may be

used with high strength bolting (ANSI B16.5 5.3.1). For all

cases the user must verify the selected bolting's ability to seat

the joint under expected operating condition. Higher strength

bolting and torque values are needed for long thrubolted

joints than shorter flanged bolting - depending on operating

conditions. **Lengths are based on ANSI B16.5 stud bolts and

raised face ends.

2.

3.

4.

1.

2.

3.

4.

1.

Table 1 : Flange Bolting Specificatiions

Valve ANSI Bolt** Torque* (ft. Lbs.)

Size Class Length Low Intermediate

(Inches) Rating (Inches) Strength Strength

150 2.5 23 61

1 300 3.0 46 122

600 3.5 46 122

150 2.75 23 61

11/2 300 3.5 82 218

600 4.25 82 218

150 3.25 46 122

2 300 3.5 46 122

600 4.25 46 122

150 3.5 46 122

3 300 4.25 82 218

600 5.0 82 218

150 3.5 46 122

4 300 4.5 82 218

600 5.75 132 353

150 4.0 82 218

6 300 5.5 132 353

600 6.75 199 531

150 4.25 82 218

8 300 6.25 199 531

600 7.5 296 789

150 4.5 132 353

10 300 6.25 199 531

600 8.5 420 1119

150 4.75 132 353

12 300 6.75 296 789

600 8.75 420 1119