7

Instructions EM39003 - 05/10

39003 Series High Performance Butterfly Valves 7

2.3 Disc Clearances

Prior to installing the valve, it is important to make sure the ID of

the pipe and pipe flanges is large enough to allow the disc edge

to swing into the opening without interference. Damage to the

disc edge can severely affect the performance of the valve. Pipe

schedule compatibility for Masoneilan valves is shown in Section

1.5 of this manual.

2.4 Opening Rotation

The Masoneilan valve is designed to open with counterclockwise

rotation of the shaft, and to close with clockwise rotation of the

shaft when viewed from above with the shaft in the vertical

position. An overtravel stop is provided in the body to prevent

overtravel of the disc in the wrong direction. This stop is not to

be used as a disc position stop. Contact with this stop means

the disc has travelled past the seat.

2.5 Installation Position

To prevent damage during installation, the valve disc must be

fully closed before installing the valve in the line. It is preferable

to install HPBVs with the shaft horizontal. This is important for

valves applied to fluids which contain particulates. For HPBVs

16" and larger, installation should always be made with the shaft

in the horizontal position.

2.6 Valve and Flange Preparation

If the valve and mating pipe are properly prepared

for installation, future problems can be avoided. All valve and

pipe flange faces should be free of dirt, grit, indentations, or

surface irregularities which may disrupt flange sealing and cause

external leakage. The valve seat and disc sealing surface should

also be inspected to eliminate any dirt or foreign material that will

adversely affect the operation of the valve.

2.7 Installation Tools

The only tool required in the installation of a Masoneilan HPBV

is a wrench suitable for tightening the flange bolts and/or nuts

required to secure the valve in-line. A hoist may be required

for handling valves 10" and larger. Smaller sized valves can

usually be installed by hand. Temporary pipe supports may be

used to keep mating flange faces parallel in order to aid in valve

installation.

2.8 Required Bolting

The tables outlined on the following pages are furnished to

provide information regarding the size, type, and quantity

of bolting recommended for the installation of Masoneilan

HPBVs. These tables are intended for use as a planning and

procurement guide. All recommendations are based on pipe

flanges in accordance with ANSI B16.5 for 2" through 24" valves

and ANSI B16.47 Class A for valves 30" and larger. Flange

bolting is not included with the valve shipment.

2.9 Unpacking and Storage Instructions

1. Check the packing list against the valve received to verify

that the size, material, and trim are correct.

2. Check to make sure that the valve and operator were not

damaged during shipment.

3. When lifting the valve, take care to avoid damage to the

flange faces, disc sealing edge, or operator. On larger

valves, lifting holes are provided on the periphery of the

valve body to aid in valve handling.

4. If the valve is to be stored before being installed, it should

be protected from harsh environmental conditions.

5. Store the valve with the disc in the closed position to

protect the sealing edge and the seat.

6. Keep the valve in a clean location, away from dirt, debris

and corrosive materials.

7. Keep the valve in a dry area with the flange protectors

attached and on a suitable skid or pallet.

8. Keep the valve in a cool location if possible, out of direct

sunlight.

2.10 Pre-Installation Procedure

1. Remove the protective flange covers from the valve.

2. Inspect the valve to be certain the waterway is free from

dirt and foreign matter. Be certain the adjoining pipeline is

free from any foreign material such as rust and pipe scale or

welding slag that could damage the seat and disc sealing

surfaces.

3. Actuators should be mounted on the valve prior to

installation to facilitate proper alignment of the disc in the

valve seat.

4. The valve should be in the closed position. Make sure

the open and closed positions of the actuator correspond

to the counterclockwise to open direction of rotation of the

valve.

5. Cycle the valve to the fully open position, then back to

the fully closed position, checking the actuator travel stop

settings for proper disc alignment.

6. Check the valve identification tag for valve class, materials,

and operating pressure to be sure they are correct for the

application.

Personal injury or property damage may result if the valve

is installed where service conditions could exceed the valve

ratings.

7. Check the flange bolts or studs for proper size, threading

and length.

2.11 Valve Installation Procedure

The Masoneilan 39003 Series High Performance Butterfly Valve

can be installed in the pipeline with the shaft in the vertical,

horizontal, or other intermediate position. Based on applications

experience, however, in media with concentrations of solid or

abrasive particles or media subject to solidification buildup,

valve performance and service life will be enhanced by mounting

the valve with the shaft in the horizontal position.

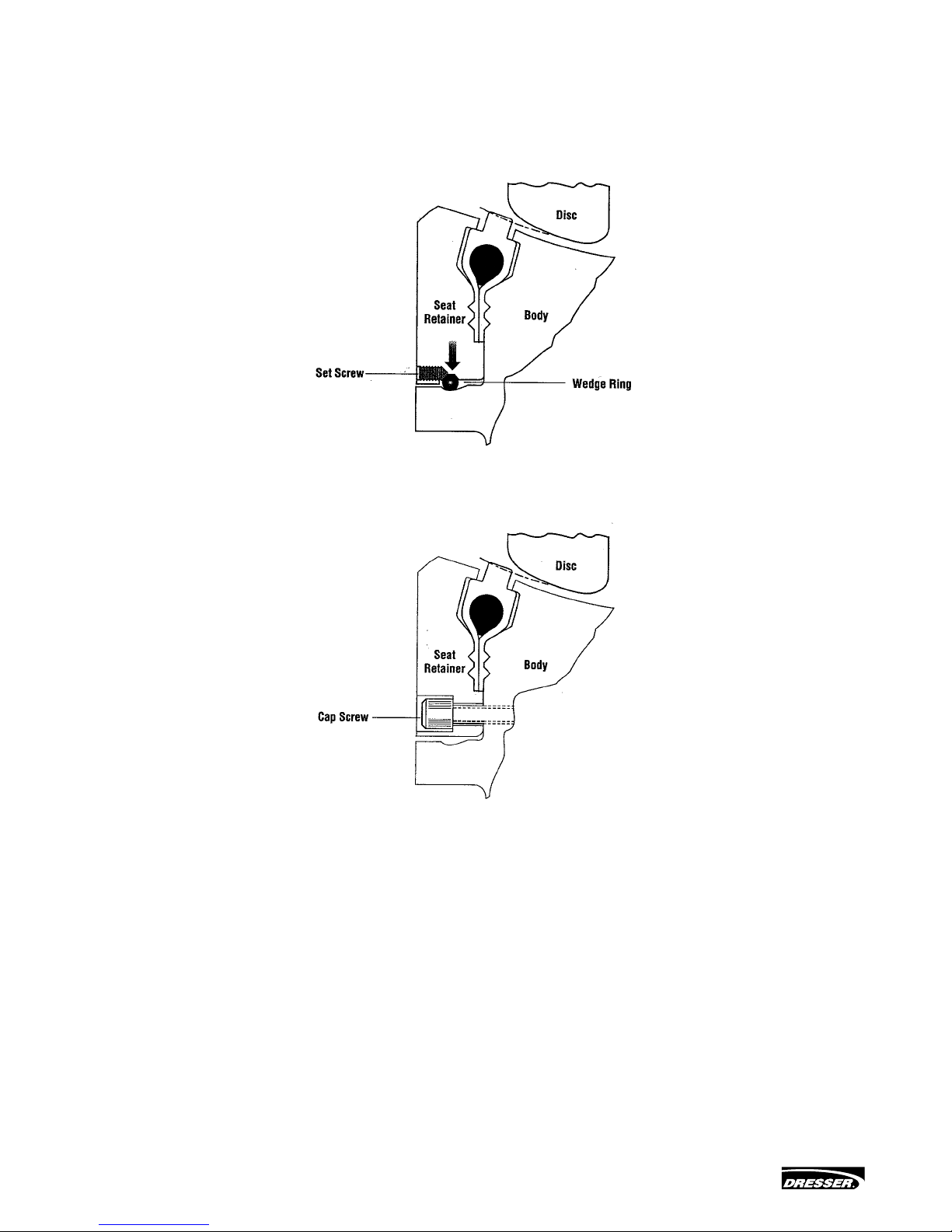

All Masoneilan valves are bi-directional and can be mounted in

the pipeline in either flow direction; however, the preferred flow

direction for all seat styles and materials is with the seat retainer

ring located upstream to provide maximum seat protection.