6

7. If the shredder screen becomes clogged, stop

the engine and pull the R clip from the pin that

protrudes under the belt guard near the front

support. Using the T grip below the chipper

tube, pull the pin out of the shredder screen.

Generally, this will cause the screen to open

downwards. If it is jammed, it can be gently

prised down using the shredder rod or a large

screwdriver.

DANGER: DO NOT ROTATE THE

SHREDDER ASSEMBLY WITHOUT FIRST

DISCONNECTING THE SPARK PLUG LEAD

FROM THE SPARK PLUG.

8. Once a jam is cleared, push the screen into

place and replace the pin. Note that the T grip

must be horizontal for the pin to go fully

through the screen. Replace the R clip.

9. If the screen is blocking repeatedly when

shredding material such as wet leaves, try

mixing some dry material with the wet material

to scour the screen clear or use the (optional

extra) bar grate. See below.

10. After shredding “stringy” material such as

palm leaves, remove the shredder chute and

check that they have not wrapped tightly

around the ends of the rotor, inside the

chamber. If so, carefully remove them with a

flat screwdriver. Some varieties of palm

leaves can be cut in the chipper tube.

NOTE: If material that is wrapped around the

shaft is not removed, the shaft becomes hot

and “boils” the oil out of the shaft bearings.

The bearings will then fail.

11. USE OF (OPTIONAL EXTRA) BAR GRATE.

For shredding soft, bulky or wet material such

as weeds or vegetable matter, an optional bar

grate can be purchased. To fit the bar grate,

turn the engine off, remove the spark plug

lead and the belt guard. Pull out both R clips

securing the shredder mesh rods, remove the

rods and the mesh. Insert the bar grate from

below and insert the rods through the grate.

Reconnect the R clips, the belt guard and the

spark plug lead.

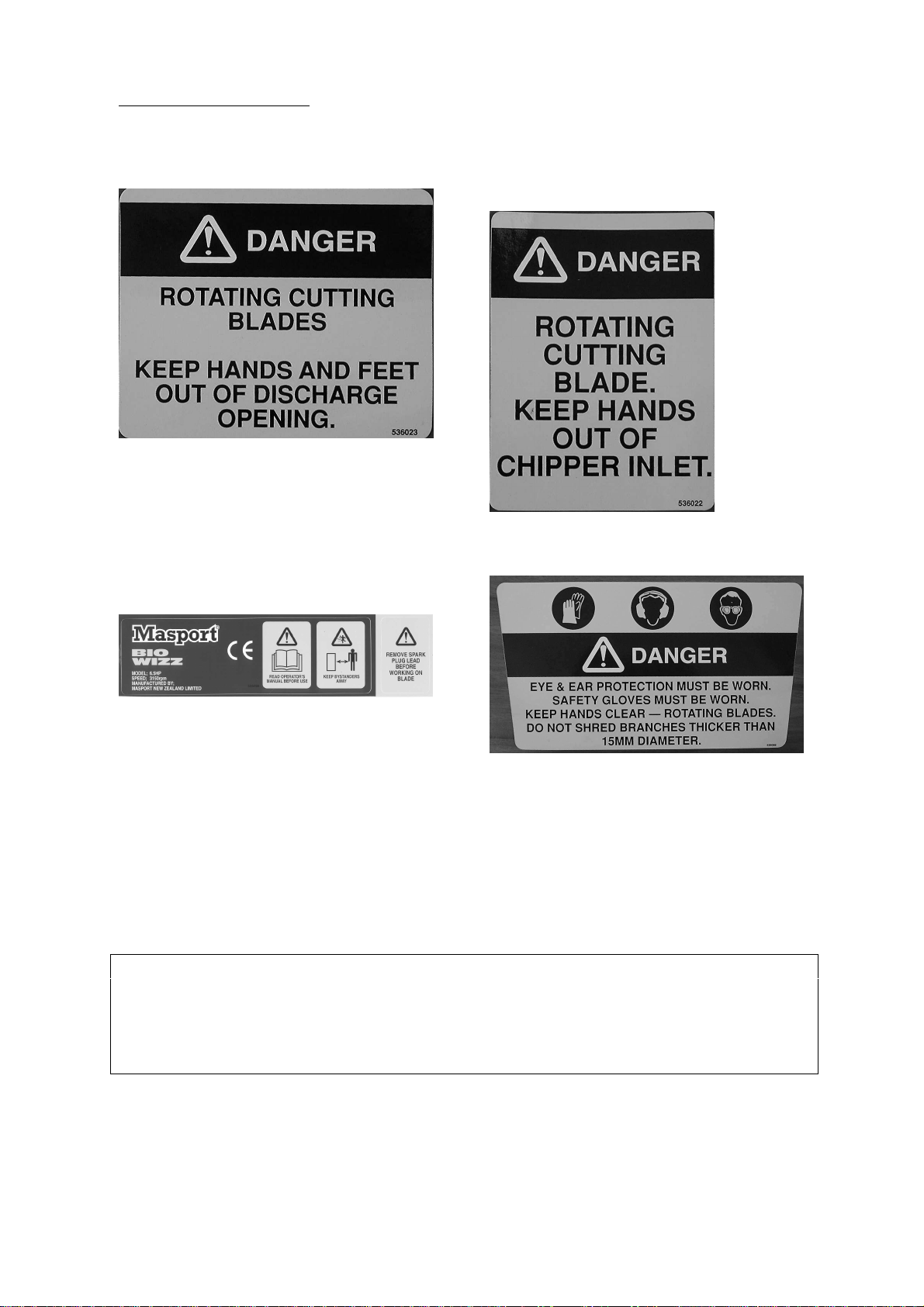

1. TRAINING

1.1 Become familiar with the owner’s manual

before attempting to operate this equipment.

1.2 Do not allow children to operate this

equipment.

1.3 Do not operate the equipment in the vicinity of

bystanders.

1.4 Carbon monoxide can be extremely

dangerous in enclosed areas; do not run the

machine in an enclosed area since the

exhaust from the engine contains carbon

monoxide, which is colourless, odourless and

tasteless.

1.5 Do not place hands or any other part of the

body or clothing inside the feeding chutes,

discharge area, or near any moving part.

1.6 Before inspecting or servicing any part of the

machine, shut off the power source,

disconnect the spark plug wire from the spark

plug, and make sure that all moving parts

have come to a complete stop.

2. OPERATION

2.1 When feeding shreddable material into the

equipment, be extremely careful that pieces of

metal, rocks, bottles, cans or other foreign

objects are not included.

2.2 If the cutting mechanism strikes any foreign

objects or if the machine should start making

any unusual noise or vibration, immediately

shut off the engine and allow the machine to

stop. Disconnect the spark plug and take the

following steps:

1) Inspect for damage

2) Replace or repair any damaged parts

3) Check for and tighten any loose parts.

Do not attempt to repair the machine unless

you are competent to do so.

2.3 Keep the engine clean of debris and other

accumulations to prevent damage to the

engine or possible fire.

2.4 Keep all guards and deflectors in place and in

good working condition.

2.5 Always stand clear of the discharge area

when operating this machine.

2.6 Keep you face and body away from the

discharge opening.

2.7 Do not overreach. Keep proper balance and

footing at all times.

2.8 Do not tamper with the engine governor

settings on the machine: the governor controls

the maximum safe operating speed and

protects the engine and all moving parts from

damage caused by overspeed. Seek

authorised service if a problem exists.

3. MAINTENANCE AND STORAGE

3.1 When this equipment is stopped for servicing,

inspection, or storage, or to change an

accessory, make sure the spark plug wire is

disconnected from the spark plug. Allow the

machine to cool before making any

inspections, adjustments etc. Maintain the

machine with care and keep it clean.

3.2 Store the machine out of reach of children

and where gasoline vapour will not reach an

open flame or spark. For extended storage

periods, run the unit dry of petrol. Always

allow the machine to cool before storing.

a) Two 13mm ring open-ended spanners.

b) 5mm allen key.

c) Shifting spanner 10”.

1. Every 5-10 hours of operation check the oil

level and top up if necessary. Change the oil

in accordance with the instructions in the

engine booklet.