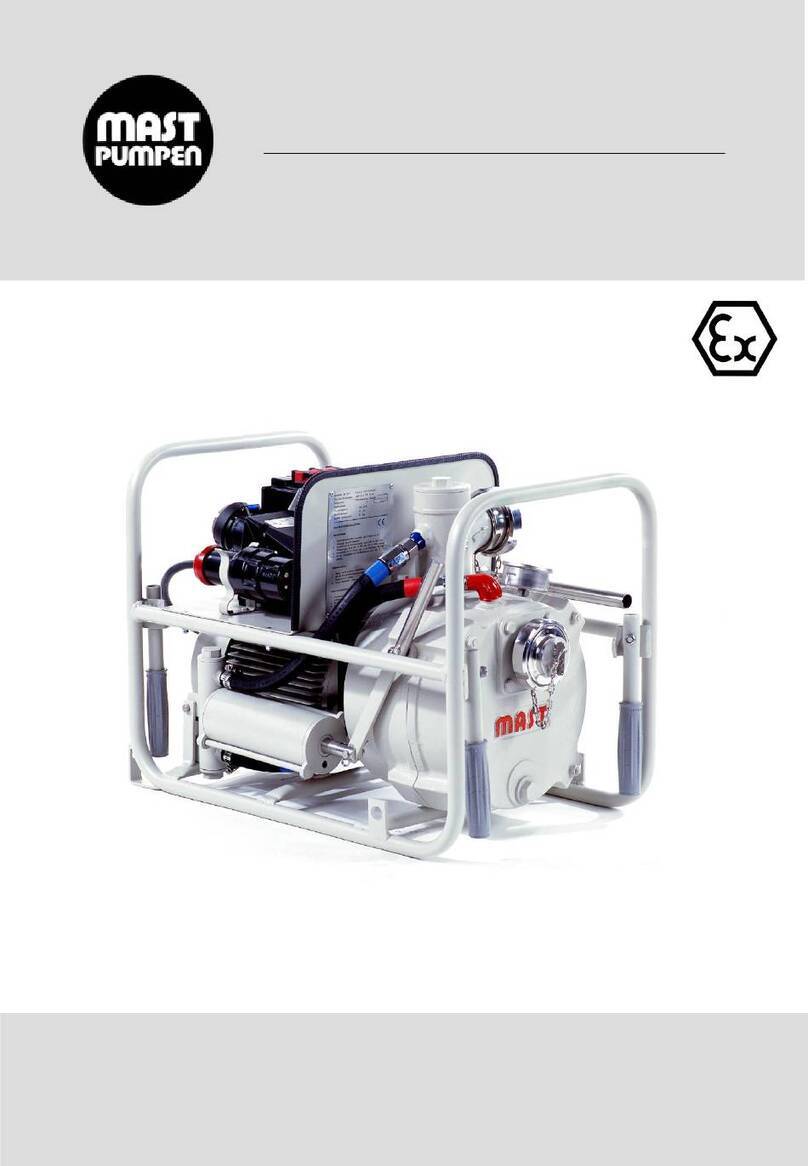

Ausführung

Einstufige horizontale Kreiselpumpe. Die mit Flüssigkeit im Gehäuse selbst-

ansaugend ist. Die Pumpe hat ein halboffenes Laufrad und eine Gleitring-

wellenabdichtung. Sie ist trockenlaufsicher und wartungsfrei.

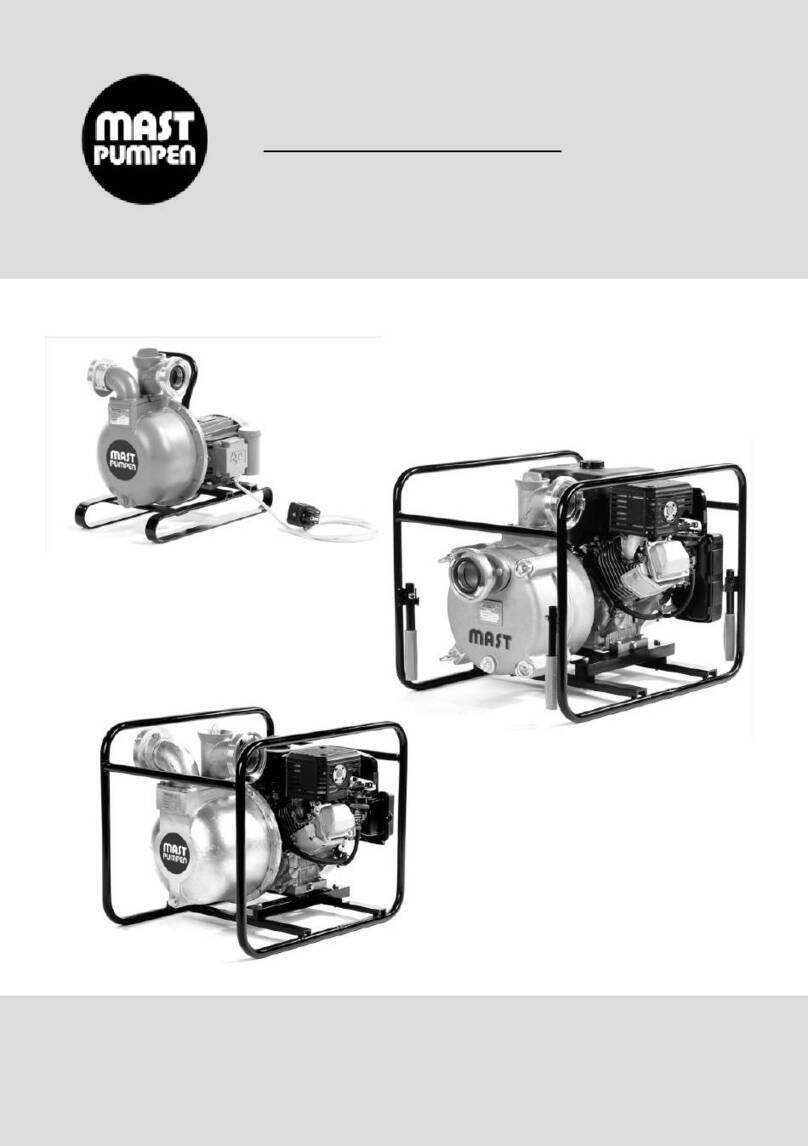

Pumpe und Motor sind in einem lackierten Stahlrahmen tragbar untergebracht.

Die Ausführungen der TUP 3-1,5 haben zusätzlich vier Handgriffe mit Handschutz.

Am Saugeingangist ein Druckmessgerät DIN 14 421 - G 556 angeschlossen

und ein Sieb mit 4 mm Maschenweite gemäß Forderung der DIN montiert.

Die Ausführungen TUP 3-1,5 C und TUP 3-1,5 CL entsprechen DIN 14 424.

Motorschutzschalter und Anschlusssteckdose sind explosionsgeschützt

Ausgeführt nach II 2 G für Explosionsgruppe IIB, T3. Es ist ein schaltbarer,

explosionsgeschützter Stecker entsprechend der Gerätekategorienach

EN 60079-14 installiert.

Werkstoffe

Gehäuse, Deckel, Krümmer: Aluminium DIN EN 1706

Laufrad: Messing DIN EN 1982

Leitapparat: Grauguss DIN EN 1561

Gleitringdichtung: Kohle/Siliziumkarbid (SiC)

Dichtungen: Nitrilkautschuk NBR (Perbunan)

Fluorkohlenwasserstoffkautschuk FKM

Motor

Asynchron-Drehstrommotor für Betriebsdauer S 1 (Dauerbetrieb) nach

DIN VDE 0530 in explosionsgeschützter Ausführung II 2 G für Explosions-

Die Absicherung des Motors erfolgt mit einem explosionsgeschützten Motor-

schutzschalter mit thermischen und elektromagnetischenAuslösern, der

auf den Nennstrom eingestellt ist. Die thermischeAuslösekennlinie entspricht

VDE 0165. Die Zulassung erfolgte für die Schutzart II2G EX ed IIC T6.

Bestimmungsgemäße Verwendung

Die tragbaren Umfüllpumpen (TUP) sind für den mobilen Einsatz in der

Gefahrenabwehr bei Feuerwehren und anderen Hilfsorganisationen für die

Förderung von brennbarenFlüssigkeiten und Schmutzwasser vorgesehen.

Sie können im industriellen Bereich ebenfalls verwendet werden, dürfen in

einem solchen Einsatzfall jedoch nicht in einer Festinstallation verbaut sein.

Vor jeder Inbetriebnahme ist das Flüssigkeitsniveau im Pumpengehäuse zu

prüfen und ggf. aufzufüllen. Kurzeitige Betriebsunterbrechungen sind zulässig,

wenn sichergestellt ist, dass das Flüssigkeitsniveau im Pumpengehäuse durch

Verdunstung oder Leersaugen nicht abnimmt. Dies kann z. B. durch den

Einsatz eines Rückschlagventils oder eines Absperrhahn erreicht werden.

( sieheAbschnitt Sicherheitshinweise ) Diese Zusatzteile sind nicht

Bestandteil des Lieferumfanges.

darf vor Einsatzbeginnnur außerhalb des Gefahrenbereichs erfolgen.

Ein kurzzeitiger Trockenlauf ( < 30 s ) ist zulässig.

3