2

GENERAL SAFETY INSTRUCTIONS

ONLY QUALIFIED SERVICE PERSONNEL SHOULD OPERATE THIS UNIT. SOME COUNTRIES MAY REQUIRE THE USER TO

BE LICENSED. PLEASE CHECK WITH YOUR LOCAL GOVERNMENT AGENCY.

•DANGER - Avoid breathing refrigerant vapors and lubricant vapor or mist. Breathing high concentration levels may

cause heart arrhythmia, loss of consciousness, or even cause suffocation.

•CAUTION - Review battery and battery charger information. Do not charge damaged batteries. Risk of overheating and

fire

•WARNING - Do not operate the vacuum pump on systems under pressure. Damage to the pump may occur

•CAUTION - All hoses may contain liquid refrigerant under pressure. Contact with refrigerant may cause frostbite

or other related injuries. Wear proper personal protective equipment such as safety goggles and gloves. When

disconnecting any hose, please use extreme caution

•CAUTION - Avoid breathing refrigerant vapors and lubricant mist. Exposure may irritate eyes, nose, throat and skin.

Please read the manufacturers Material Safety Data Sheet for further safety information on refrigerants and lubricants

•CAUTION - Do not use this equipment in the vicinity of spilled or open containers of gasoline or other flammable

substances. Make certain that all safety devices are functioning properly before operating the equipment

•CAUTION - THIS EQUIPMENT IS INTENDED FOR USE OF FINAL EVACUATION OF A REFRIGERANT SYSTEM WITH

0-3 PSI (0-0.2 BAR)

•CAUTION - DO NOT RUN THIS EQUIPMENT WITH LOW OR NO OIL. RUNNING THIS EQUIPMENT WITH NO

LUBRICATION WILL CAUSE PREMATURE FAILURE

•WARNING - Do not evacuate combustible, explosive or poisonous gases

•WARNING - Do not evacuate gases that corrode metal or react chemically with pump oil

•CAUTION - The temperature of evacuated gas shall not exceed 176˚F (80˚C) and ambient temperature shall be 41 -

140˚F (5 - 60˚C)

•WARNING - No not touch the vacuum pump’s hot surface during operation

•WARNING - Do not block air outlet

INITIAL PREPARATION

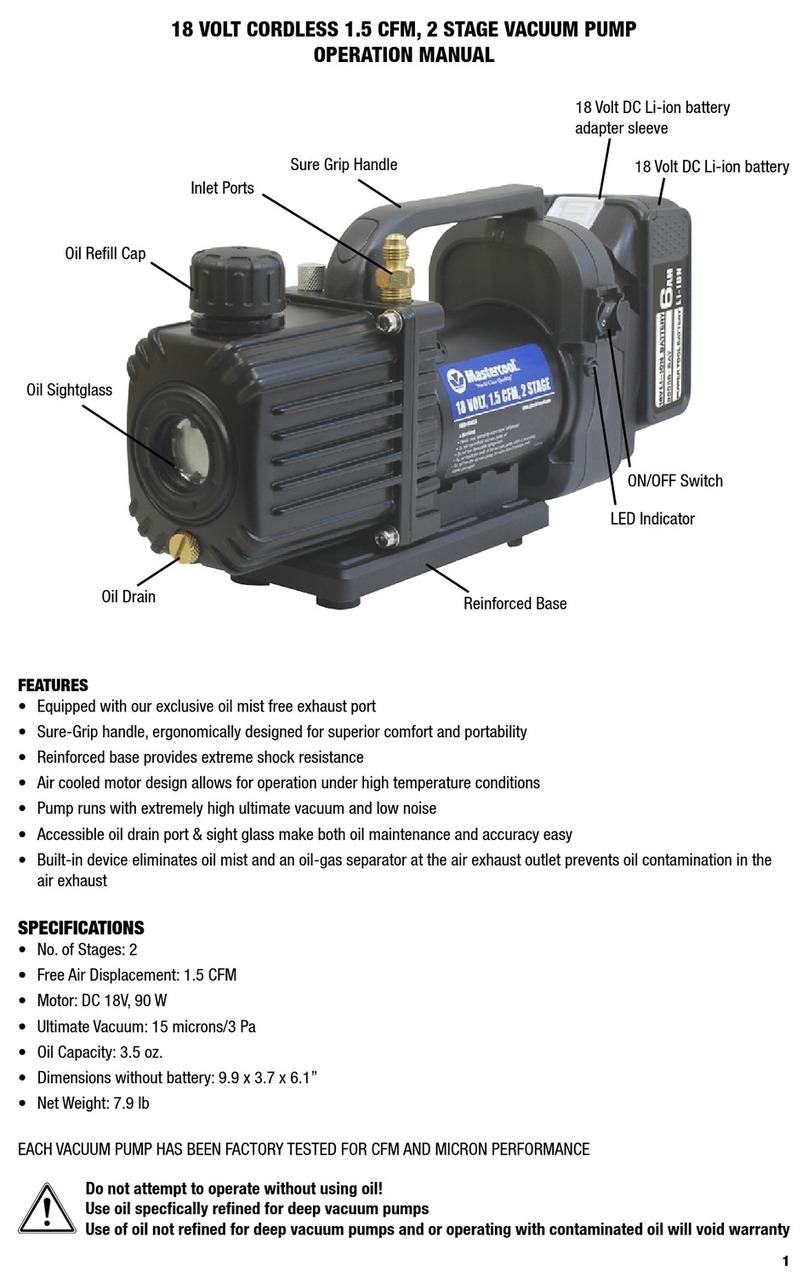

• Fully charge the 18VDC Li-ion battery.

OIL FILL

•CAUTION: DO NOT RUN THIS EQUIPMENT WITH LOW OR NO OIL. RUNNING THIS EQUIPMENT WITH NO

LUBRICATION WILL CAUSE PREMATURE FAILURE.

• This vacuum pump has been tested at the factory and shipped with only trace amounts of oil. OIL MUST BE ADDED

BEFORE OPERATING! Failure to add oil will damage cartridge and void warranty!

a. Make sure the oil drain valve located below the front casing is closed before attempting to add oil.

b. Remove the oil fill plug from the top of pump and insert the oil bottle into the fill port.

c. Slowly add oil until oil level rises to the top of the oil level line. Do not overfill with oil!

d. Replace oil fill port.

CHECKING OIL LEVEL

a. Open the gas ballast valve (small fitting located next to the handle) one turn.

b. Start pump and run with intake port capped for about two minutes. Observe the oil levelwith the pump running. The

oil level in the sight glass should be even with the level line.

c. If the level is low, open the intake port and run pump for 15 seconds, stop pump and observe oil level again. Add a

small amount of oil as needed.

NOTE: To achieve good final vacuum levels, the oil level should be visually seen through the sight glass.

GAS BALLAST VALVE

The gas ballast valve must be opened 1/4 turn for the first part of the evacuation procedure. This will help to eliminate

moisture and extend the life of the vacuum pump. After about two minutes close the valve and continue the evacuation

procedure to reach ultimate vacuum. Failure to close the valve completely during the final evacuation will result in high