tective equipment such as hearing protection reduces the risk of injury.

• Keep children and other persons away when using the product. Distractions may cause you to

lose control of the product.

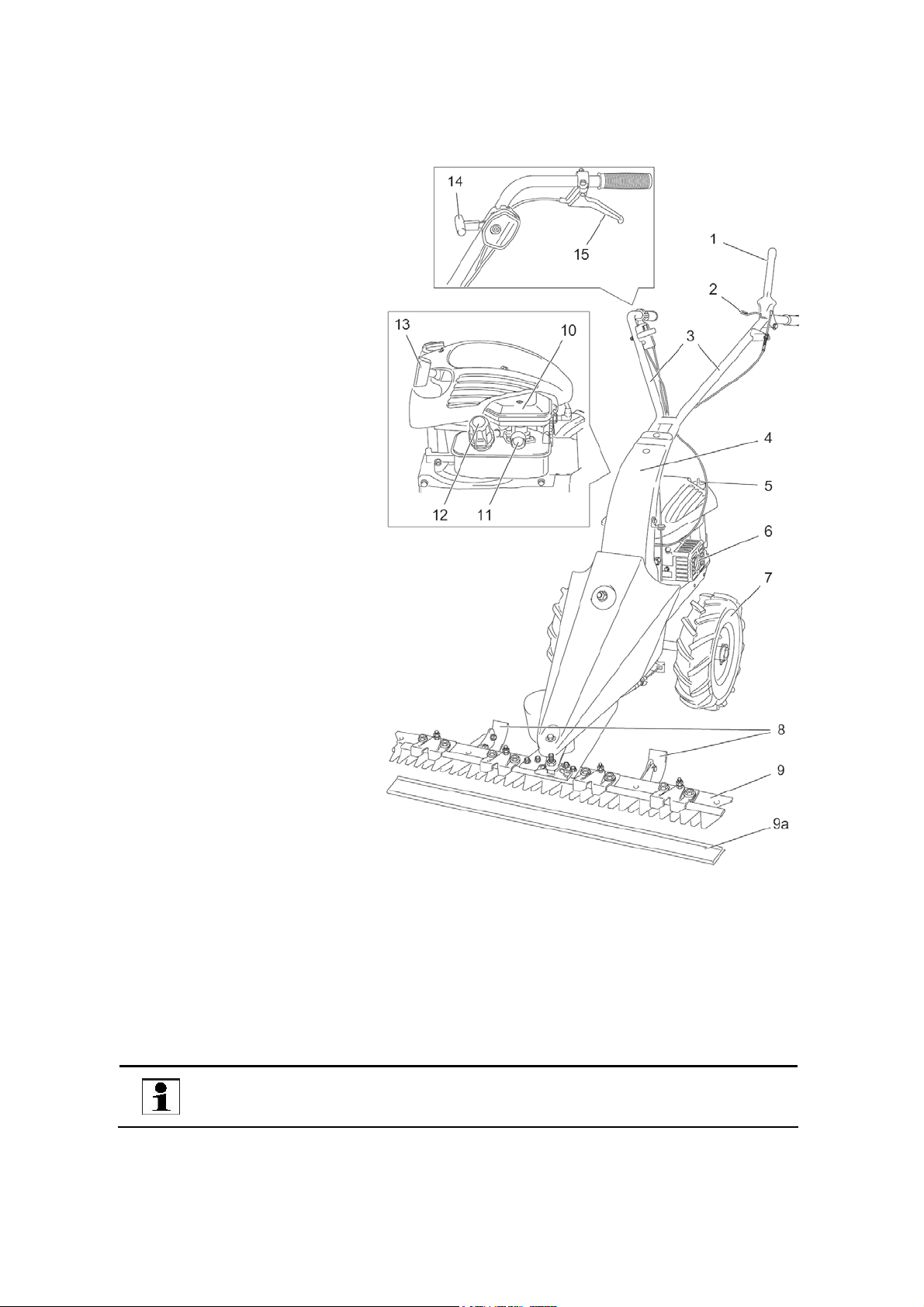

• All parts of the product must be correctly installed to ensure faultless operation.

• Young people under 16 years of age and users who are not sufficiently acquainted with its

operation must not use the product.

• The product may be used only when in a faultless condition. If the product or a part of it is

defective, it must be repaired by Dealer’s Service.

• The surroundings must be free of highly-flammable or explosive materials.

• Do not operate the product unless the protection devices are fitted.

• take care at the cutting tool – maintain an adequate safe distance.

• Exercise caution with tools that run-on. Before commencing work on these tools, wait until they

have come to a complete standstill!

• Danger of poisoning due to exhaust fumes! Do not start the motor or use the product in

enclosed spaces.

• Never leave the product unattended with the motor running.

• Check the fuel system for leaks or defective parts on a regular basis.

• Always switch off the motor when transporting or refuelling.

• Carefully remove overflowing fuel without delay.

• Conversions, unauthorized modifications and the use of non-approved parts are prohibited.

• Always heed the applicable national and international safety, health and labour regulations.

• Work with caution and only if you are physically fit: Working under the effects of fatigue, illness,

alcohol, medication and drugs is irresponsible.

• Only the maintenance work and trouble shooting activities described here may be carried out.

All other work must be carried out by Dealer’s Service.

• Use only genuine spare parts. Only these spare parts are designed and suitable for the product.

The use of other spare parts not only invalidates the warranty, it also presents a danger to

yourself and your environment.

Raynaud's syndrome (white-finger syndrome)

The frequent use of vibrating devices can damage the nerves of persons whose blood flow is

impaired (e.g. smokers, diabetics). Fingers, hands, wrists and/or arms in particular show some or

all of the following symptoms: Pain, prickling, twinges, deadening of limbs, pale skin.

If you notice anything unusual, stop working immediately and consult a physician.

You can substantially reduce the risks if you adhere to the following instructions:

• Keep your body and particularly your hands warm in cold weather. Working with cold hands is

the main cause!

• Take regular breaks and move your hands. This encourages circulation.

• Ensure that the product vibrates as little as possible through regular maintenance and tight parts

on the product.

Product-specific safety information

CAUTION

Product damage!

The product is supplied without motor oil.

Make sure it is filled with motor oil before using for the first time.

The oil level must be checked and topped up refilled each time before using the

motor.

Operating the motor with insufficient oil will damage the motor.

Dirty oil or two-stroke motor oil reduces the service life of the motor.

The motor oil must be changed after the first five operating hours.

Use the specified motor oil.