`

Welcome to MasterGage

Dear Customer:

I’d like to welcome you into our family of valued customers. MasterGage Corporation is a

manufacturer of high quality, precision tooling for those who demand the very best tools for their

craft.

All MasterGage products are innovative and original. To illustrate this point, I have been

awarded eight United States Patents, with other patents pending, in the development of the

MasterGage system. The tools that I present to you are the result of my 45+ years as a

practicing mechanical engineer involved in many industries designing precision tools and

mechanisms. As a woodworker, I found aligning, tuning and troubleshooting my machines to be

unnecessarily difficult. I also found setting the machines up for various operations and set-ups

time consuming and exasperating. This frustration led me to develop the MasterGage system.

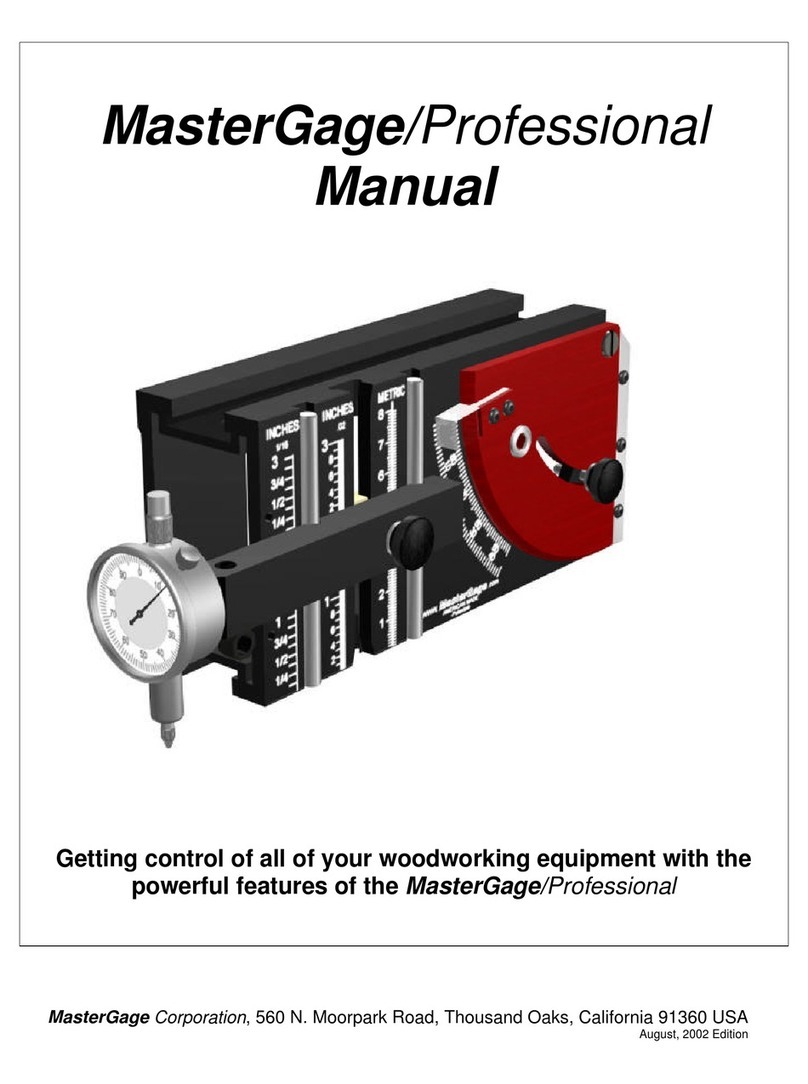

The MasterGage/Classic is a powerful tool, as this Manual will demonstrate. It will allow you to

align, calibrate, trouble shoot and reduce set up time on any piece of equipment found in the

wood shop with ease. With the MasterGage/Classic you have control over any machine you

presently own – or any you plan to acquire in the future. Easily portable, you can use the

MasterGage/Classic on any machine in the production shop, in the field or in the home shop. No

need to rely on any machine scales, since you are always reading the laser precision scales on

the MasterGage/Classic or the super accurate Dial Indicator. You will also get automatic

conversions of any dimension from one system to another, whether it is in fractions, decimal

inches, millimeters or centimeters. Now you will have control of all your machinery.

Do keep in mind that all machines must be aligned and calibrated on a regular basis –

IT IS NOT A ONE TIME EVENT. The Classic really shines when it comes to set up and re-setup

of your machinery for any operation you desire. Machine set up that took hours, will now only

take minutes. With the user-friendly MasterGage/Classic, you can to get to the fun/business of

woodworking fast!

For even more versatility, I’ve developed many optional Accessories that allow you to

“customize” the MasterGage/Classic to your particular needs. As you grow in your measurement

and calibration needs, you will always find an Accessory to fit your requirements.

Craftsmen involved in any of the following disciplines will find these tools invaluable.

1. Woodworkers 5. Furniture makers 9. Machinists

2. Model makers 6. Cabinet makers 10. Tool makers

3. Pattern makers 7. Serious hobbyists 11. Sheet metal workers

4. Finish carpenters 8. Boat builders 12. And many other craftsmen

Thank you for your business!

Paul Reilly

President, Founder & Inventor

MasterGage.com MasterGage.com