Masterpiece Module Kits

FreeMo Module Kit Assembly Instructions

For tips, watch Instructional Video at http://www.youtube.com/watch?v=fKleBFFclaU

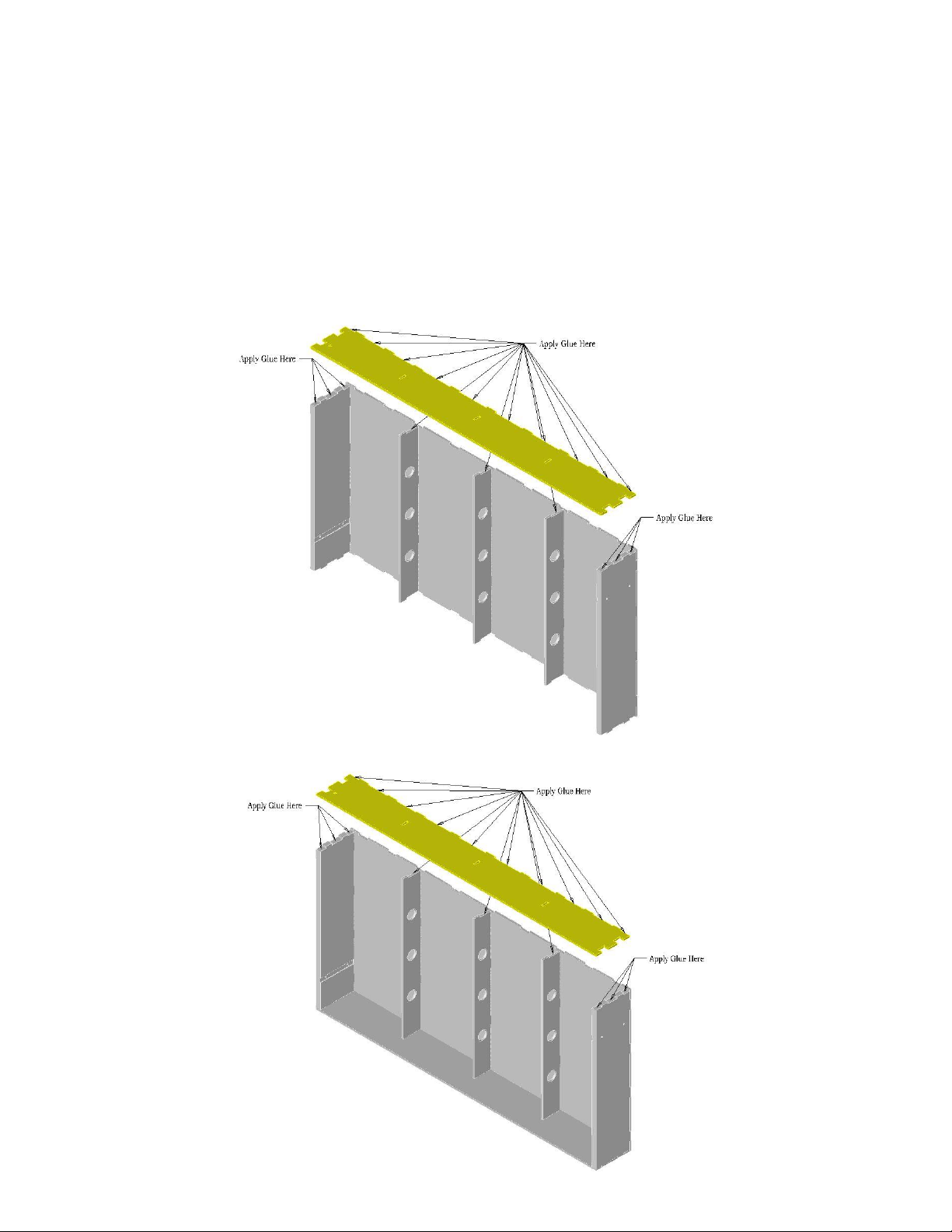

Tools Required –flat, sturdy work surface

Quality grade wood glue such as Tite Bond III

Hammer or mallet and wood block, Philips Screwdriver

DO NOT press pieces together before gluing. All pieces are cut on a CNC router and are a precision

press fit. Assembling them without glue to check the fit may seem like a good idea, but when you

try to disassemble to add glue, you risk delaminating parts of the plywood.

When using a hammer, place a block of wood on the module components as a buffer, tapping on

the block of wood rather than the module components. This will prevent the hammer from marring

the module component surface. Also, make sure the module is supported by a sturdy work surface

that will withstand the action of the mallet or hammer. (the floor works fine for this)

1. Using the sandpaper pieces included in this kit, remove all the fuzz and splinters on the

perimeter of all the parts.

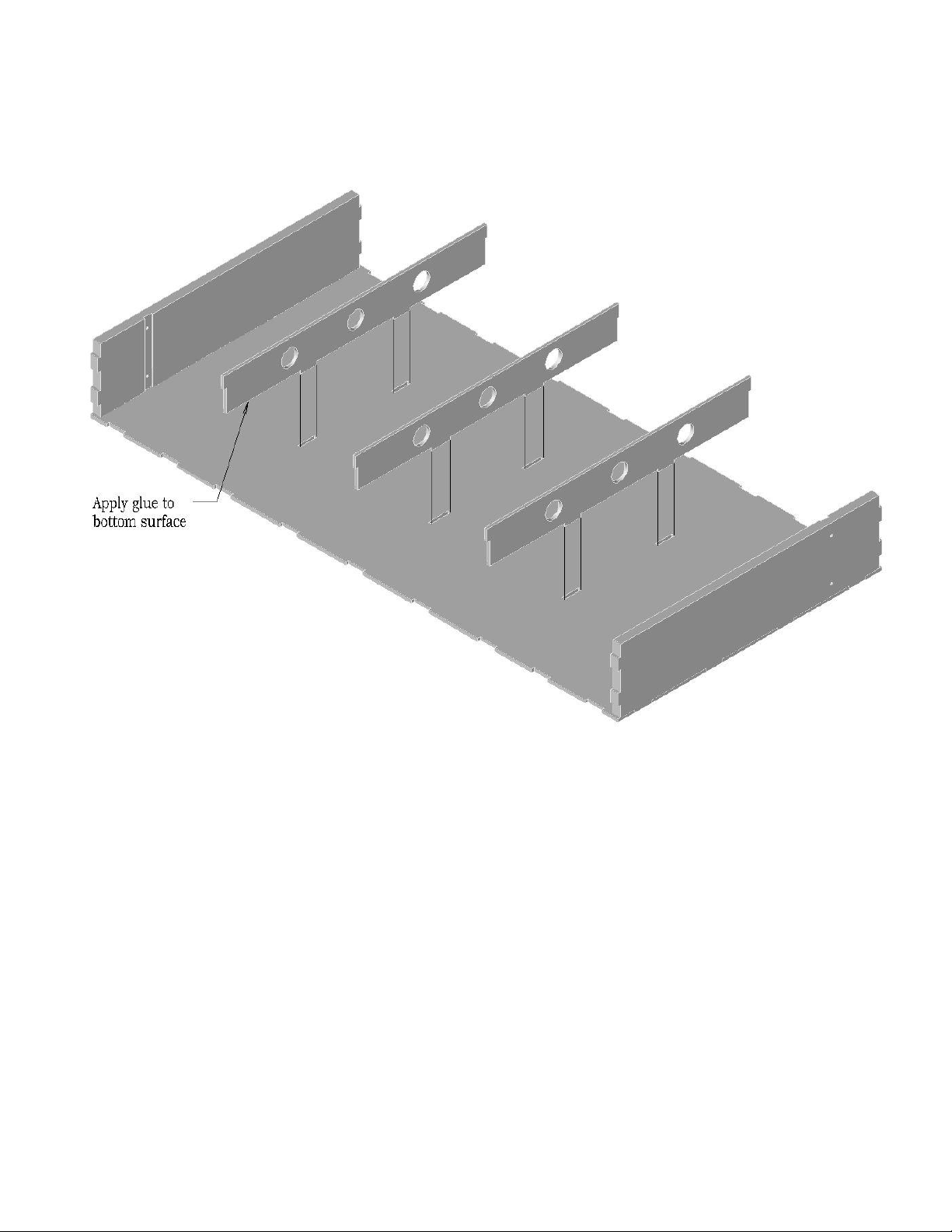

2. Lay out all the parts and get familiar with how they interlock and fit together. Refer to PARTS

LIST on Page 4.

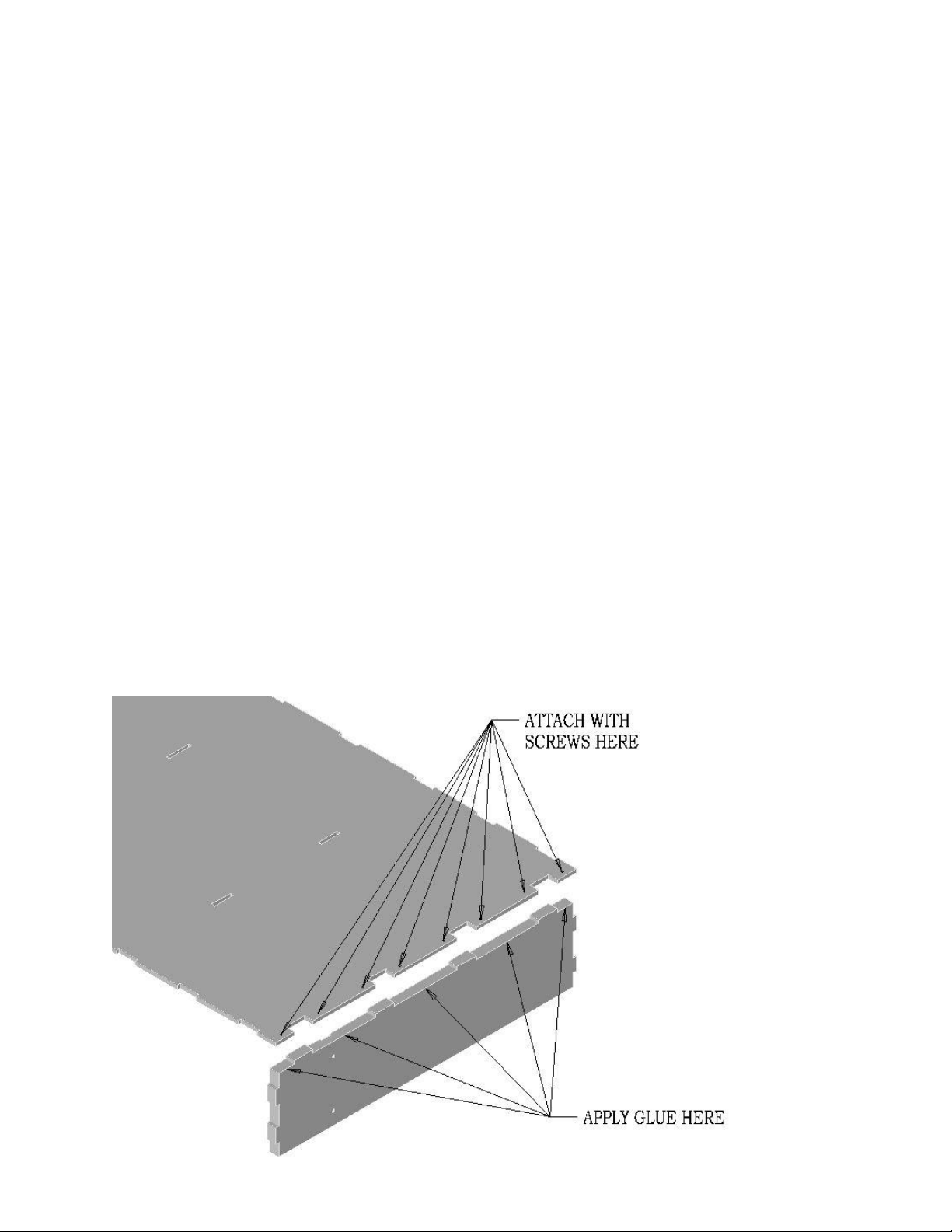

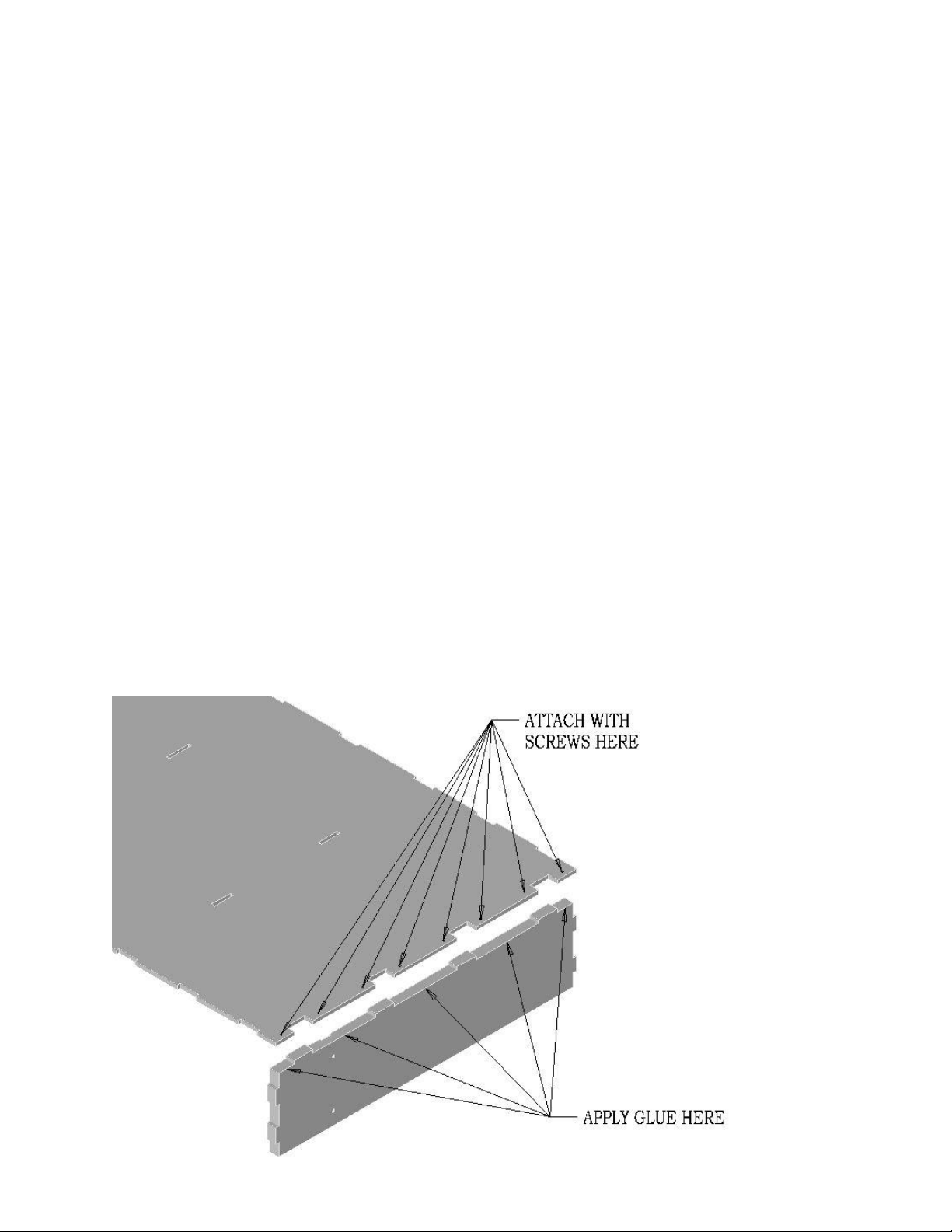

3. We will begin assembling this module right side up on a sturdy work surface. This could be a

table, workbench or the floor if it is flat. Select one of the Deck End Plates and make sure the finger

sizes match the slot sizes in the deck and the alignment pin in the end plate is on the outside of the

module. Spread glue on the top edge of the Deck End Plate between the fingers. Fit the Deck in

place as shown, using the other end plate to raise the other end to keep the Deck parallel with the

work surface. Make sure Deck is tight against the End Plate fingers and install #6 –5/8 FH Wood

Screws as shown. Repeat with other end.