the required heat To turn any hotplate off, simply turn the

knob back to "0".

Warning!

- Beware of inexpert handling!

- Never leave the hotplates on unused!

- Only use flatbottomed pots and pans, and make sure

that the diameter of the pan is never smaller than the

diameter of the hotplate it is being used on.

Ignition

Turn on the switch upstream of the appliance.

A) Hot plates

Turn the knob corresponding to the hotplate you wish to

use, to a number between 1 and 6.

The pilot lamp will light up as soon as the appliance is on.

We advise first turning the hotplate up to maximum tem-

perature. Once this has been reached, turn the knob to

Before beginning installation, remove all packaging from

the appliance. Some parts are protected with an adhesive

film which should be carefully removed.

Any remnants of glue should be thoroughly cleaned using

suitable substances such as benzine. Under no circum-

stances should abrasive substances be used.

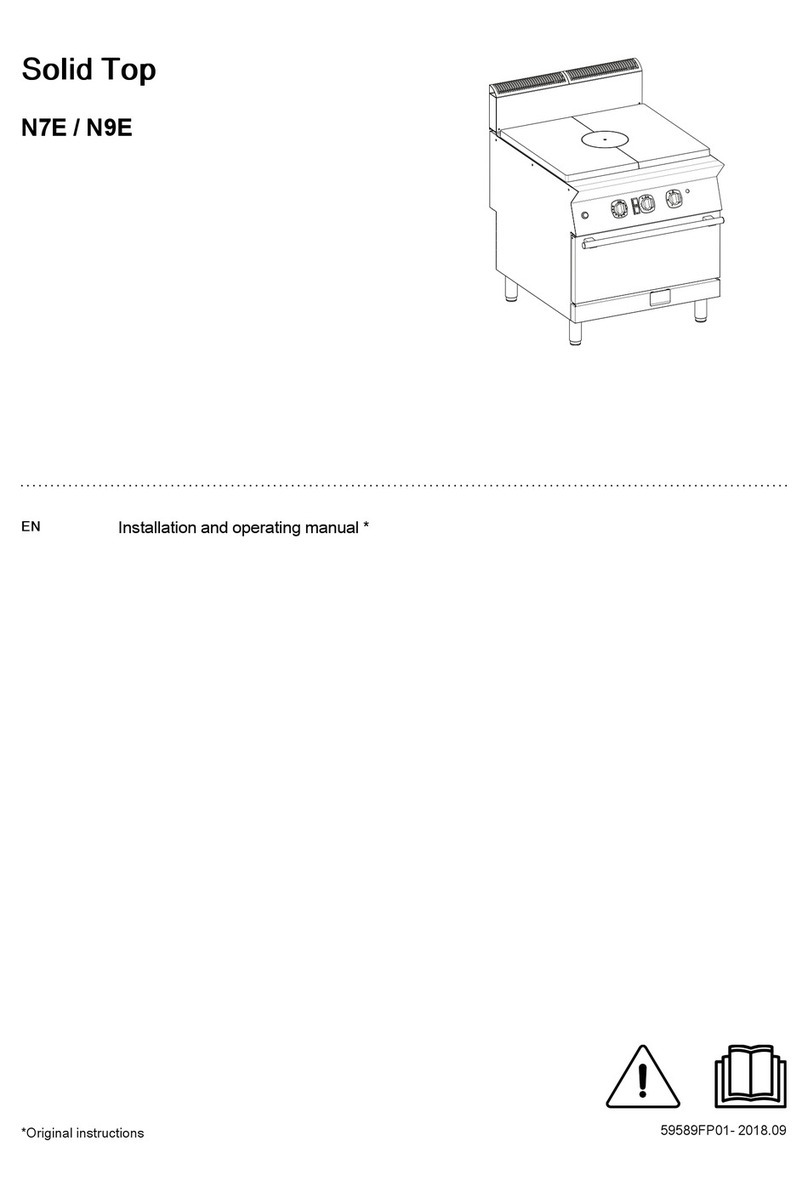

Fit the legs to the appliance. The appliance must be level-

led using a spirit level.

Slight irregularities can be levelled by adjusting the feet

themselves.The main switch or plug should be located in

the vicinity of the appliance and easy of access.

We recommend installing the machine under a range

hood so that all the fumes are removed as quickly as pos-

sible. Make sure that all fire prevention standards and sa-

fety precautions are strictly adhered to.

Legal and technical requisites

When installing the appliance, the following safety stan-

dards must be adhered to:

- Local accident prevention standards

- Current CEI standards.

Installation

Installation, start-up and maintenance should only be car-

ried out by expert personnel.

All work required to install the appliance should be carried

out in compliance with all local standards and regulations.

The manufacturers decline all responsibility where poor

performance is due to incorrect installation in disregard of

the above conditions.

Warning!

In compliance with international regulations, when

connecting the appliance to the mains power supply, a

device with a minimum aperture of 3 mm between con-

tacts must be fitted upstream of the appliance, al-

lowing omnipolar disconnection of the appliance from

the mains.

Wiring

When choosing the lead wire, make sure it has the fol-

lowing characteristics: it should be at least of the H07 RN-

F type and its section should be large enough for the ap-

pliance (see "Technical specifications and dimensions",

page 5). Two lead wires are needed for models with a vol-

tage of 230 V 3 AC. The terminal boards are in the terminal

box located underneath the appliance on the left hand si-

de. Pass the wire through the core hitch and wire clamp,

plug the leads into their terminals on the board and secure

them.

The earth lead must be a little longer than the others so

that it is the last lead to disconnect if the wire clamp

breaks.

Unipotential

The appliance must be connected up to a unipotential sy-

stem. The connection screw is located underneath the ap-

pliance on the right hand side, close to the electrical pa-

nel. It is labelled.

Warning!

The manufacturers cannot be held responsible for any

damage due to inadequate or incorrect installation.

Under such circumstances the guarantee will be consi-

dered null and void.

INSTALLATION INSTRUCTIONS

016--03 5