Appendix A

Page 8

1. Appendix A

Adjustment of the overrun brake with automatic reverse

The brake system consists of a telescoping drawbar and a braked axle, which are con-

nected by means of a mechanical gearbox. The brake is activated by the force exerted

between the trailer and the towing vehicle when the towing vehicle slows down.

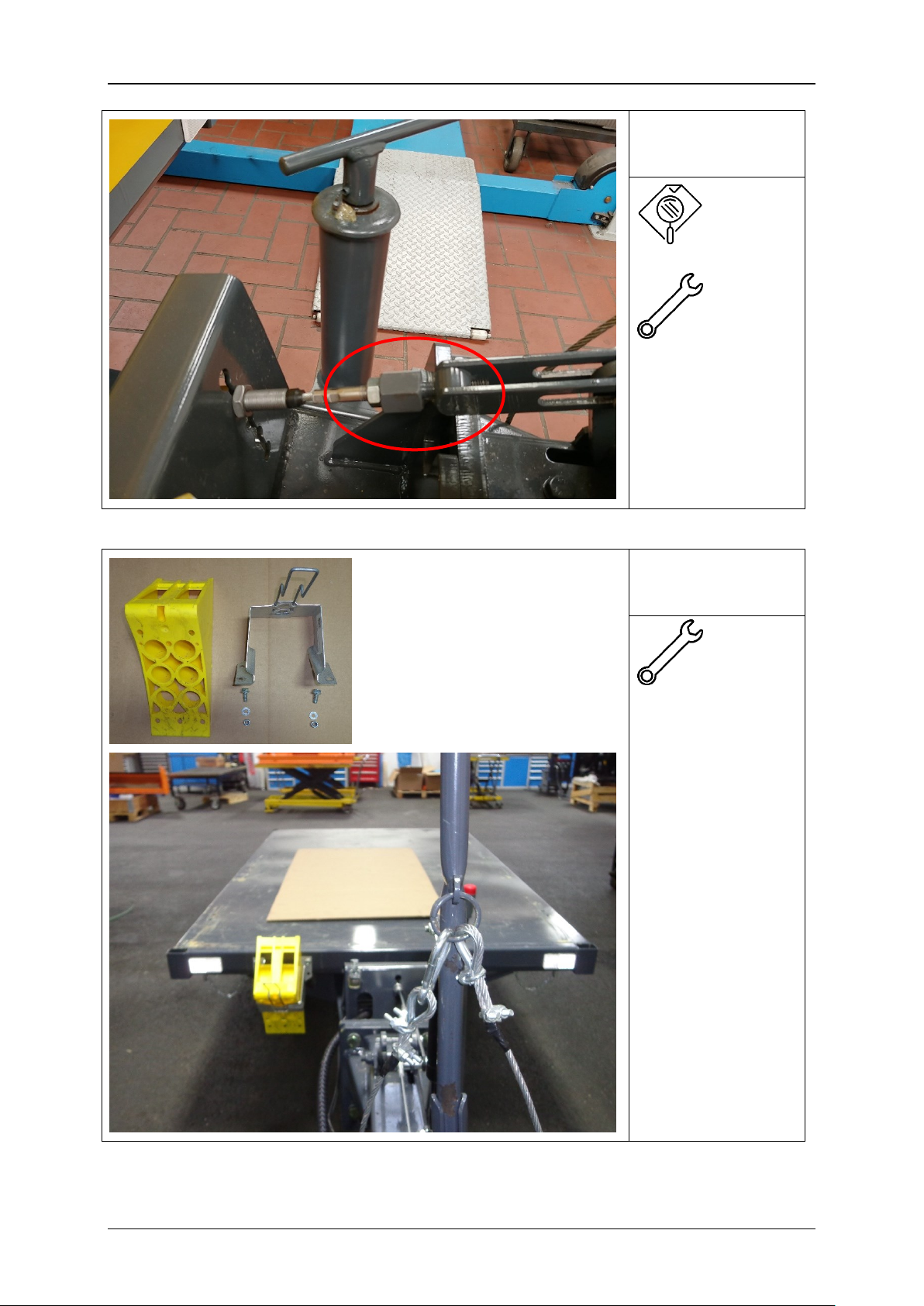

In case the vehicle is separated from the trailer, the brake system has an emergency

brake function, in which the hand lever is connected to the tractor by a steel cable that

actuates the hand lever. The hand brake lever is supported by the gas spring.

The brake system is equipped with an emergency brake, which is operated with a hand

lever. The emergency brake works in both directions of travel. The hand lever is sup-

ported by a gas spring, which applies the force necessary to stop the vehicle in ac-

cordance with the safety requirements.

To prevent the trailer wheels from blocking when driving in reverse, the brake is

equipped with an automatic reverse function. This releases the brake again as soon as

the wheels rotate counter to the direction of travel.

Instructions for adjusting the brakes

After adjusting the brakes and the first trip under full load, check the set-

tings after 50 hours and then every 200 hours.

Raise the trailer so the wheels can turn freely.

Always use suitable lifting gear and suitable safety stands.

Observe occupational safety regulations.

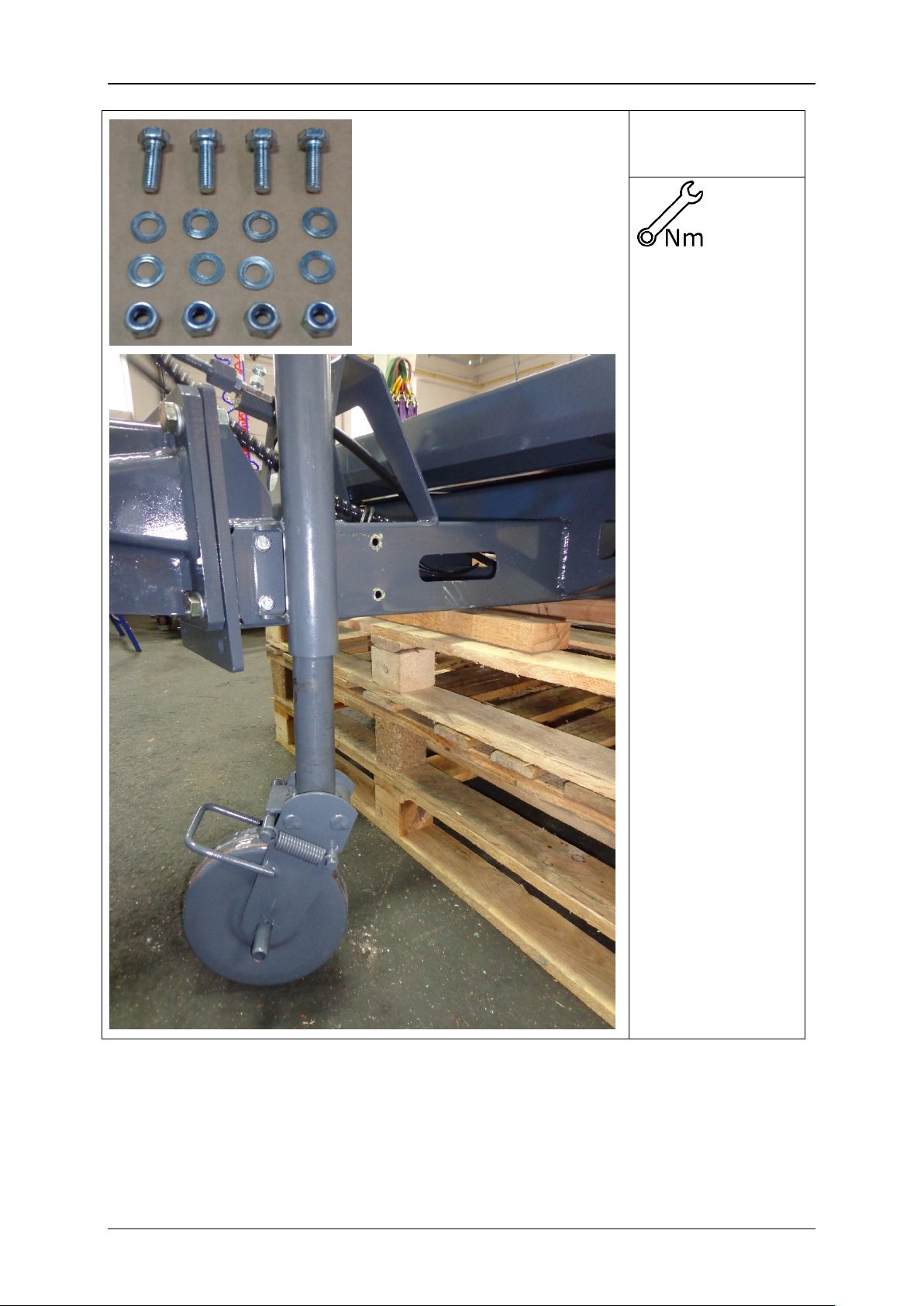

1. Disconnect the brake cable that connects the brake lever C with the hand brake lev-

er B at position A (Figure 1)

2. Push a screwdriver into the opening (Figure 2 - Ref. V). Here you will find the adjust-

ing screw. Turn the wheel by hand in the direction of the arrow while also turning

the adjusting screw, likewise in the direction of the arrow. Turn the adjusting

screw until the wheel is braked (hard to turn by hand).

3. Now turn the adjustment screw in the opposite direction until the wheel can turn

freely in the direction of the arrow.

4. After adjusting both brakes for the axle, check by hand whether both levers (Figure 1

- Ref. C) have the same stroke. If further adjustment is necessary, repeat step 2.

5. The maximum stroke of the cable / drawbar during operation should be about 75 mm

for a 150 mm brake lever. Adjust the levers so that they are perpendicular at half

stroke.

6. Check whether the telescoping drawbar (Figure 1) is fully extended and the lever

(Figure 1 - Ref. E) that pulls on the cable is fully retracted. Connect and adjust

the linkage under these conditions (Figure 1 - Ref. F) to prevent any backlash

7. Hitch the trailer to the tractor, pull the emergency brake lever and make sure that the

brake is effective both in forward and reverse and that the right and left brake ex-

ert an even braking force.

When pushing in reverse the tension of the hand brake lever will automatically

increase.

8. Release the hand brake lever again and check whether the reverse movement is

free.