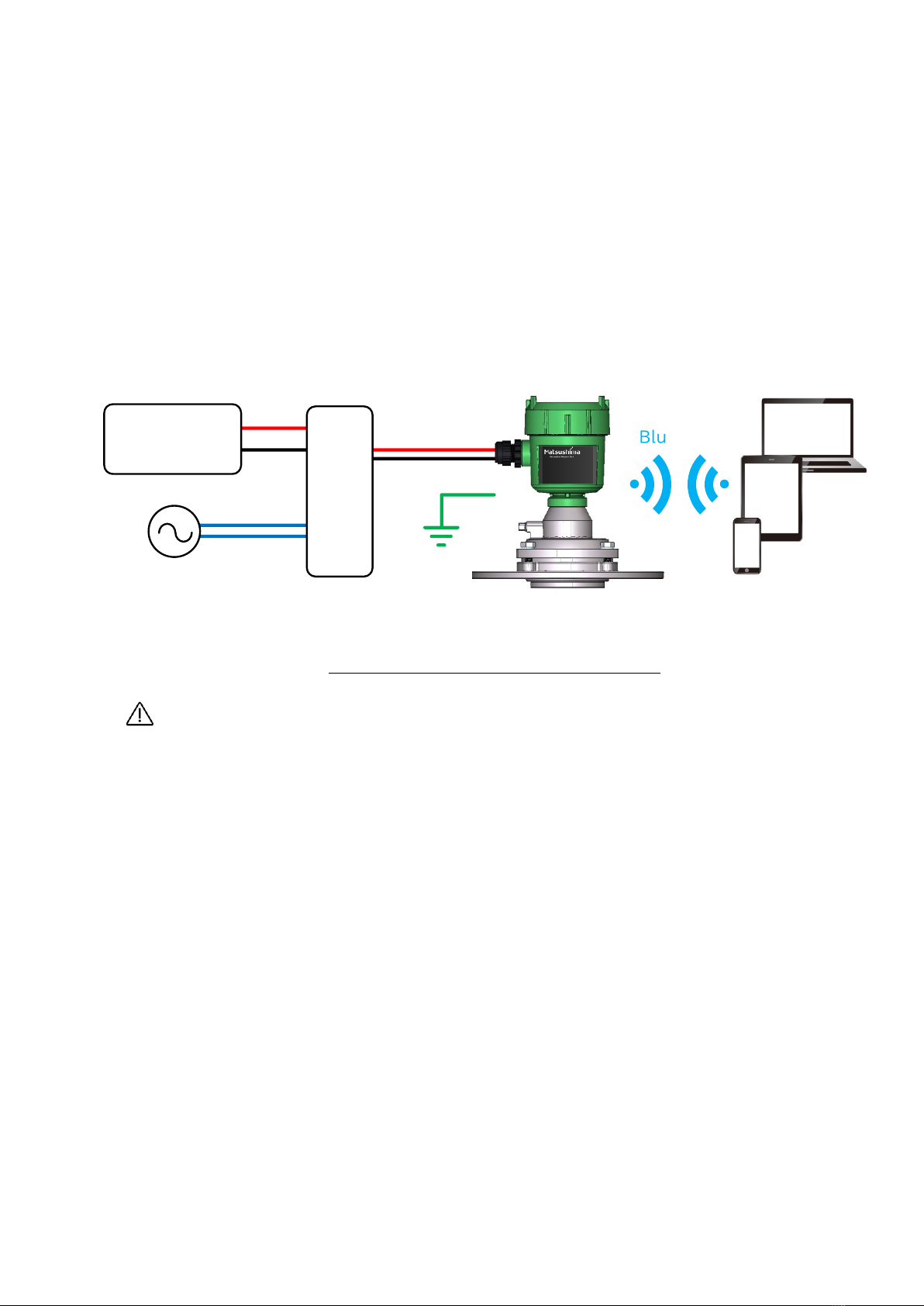

・Bluetooth wireless communication

・Bluetooth とは

Bluetooth is wireless communication technology between digital devices in relatively short

distance by connection with a PC or a smartphone. No need to connect with devices by an USB

cable, and wireless communication with data can be available at anywhere in short distance

(within approx. 10m viewable area).

・通信可能範囲にて

Distance for Bluetooth communication is within approx. 10m viewable area. Available

connection distance will be changed by any block of walls and metals, or around situation and

building shape. Make sure of using no barrier place, as much as possible.

・セキュリティについて

Make sure that we do not have any responsibility for any case of data leaking. We recommend

setting the password due to higher security.

Refer to the Instruction manual for an app of Reader level transmitterfor setting the

password. If the password is set up, Reader level transmitter will be locked and parameters

including other specifications will not be available to be changed. We recommend that the

password must be updated routinely for higher security.

・本機の機器認定について

No need a license of radio station to use because this product has been approved upon Radio

Act as the wireless system for power saving data communication. However, breaking, remodeling,

and removing nameplate may be punished. This approval can be applied only in Japan.

・使用周波数と注意事項

Usable frequency of Bluetooth (range 2.4GHz) will be used for in-house radio stations (license

required), specified low power radio stations (no license required) for mobile facilities in factory

at fields of household appliances, industry, science, medical devices and mobile detectors in

factory, and amateur radio stations (license required).

1. Make sure of confirming no in-house radio station for mobile detector, specified low power

radio station and any amateur radio station near before starting to use.

2. Keep a distance from any electric device as much as possible. If any harmful radio wave

interference occurred, immediately cut the power supply to the device.

3. In case of strong radio wave from any radio station or wireless device, it may not be able to

connect normally.

4. Please be sure that connection with Bluetooth will cause the battery of the connected device

drains faster.

・Trademark/Software license

-The logo Matsushima Measure Tech Co., Ltd.is our brand and registered trademark.

-Copyright of FM79 Smart Com.is reserved by Matsushima Measure Tech Co., Ltd..

-The Bluetooth and its logo are the registered trademark of Bluetooth SIG, Inc..