-8-

8. ENVIRONMENTAL CHARACTERISTICS

8.1Operating temperature Range -10 to +50 oC

8.2Operating humidity Range 10 to 90% RH (No condensation allowed)

8.3Storage temperature Range -20 to +60oC

8.4Storage humidity Range 10 to 95%RH(No condensation allowed)

(24hours)

* Test procedure : Placethe card reader in the standard environment (temperature:20+/5oC,

humidity:35 to60%RH). Leave it for 12 hours, and measure the functions.

Make sure no abnormality is found.

8.5 Vibration :Vibration sweep 10 to 50Hz/m

X,Y,Z directions

8.6 Shock durability 294 m/s2(30 G)

8.7 Others Make sure any source of noise that may deteriorate

the characteristics of the card reader is not present around the card

reader.

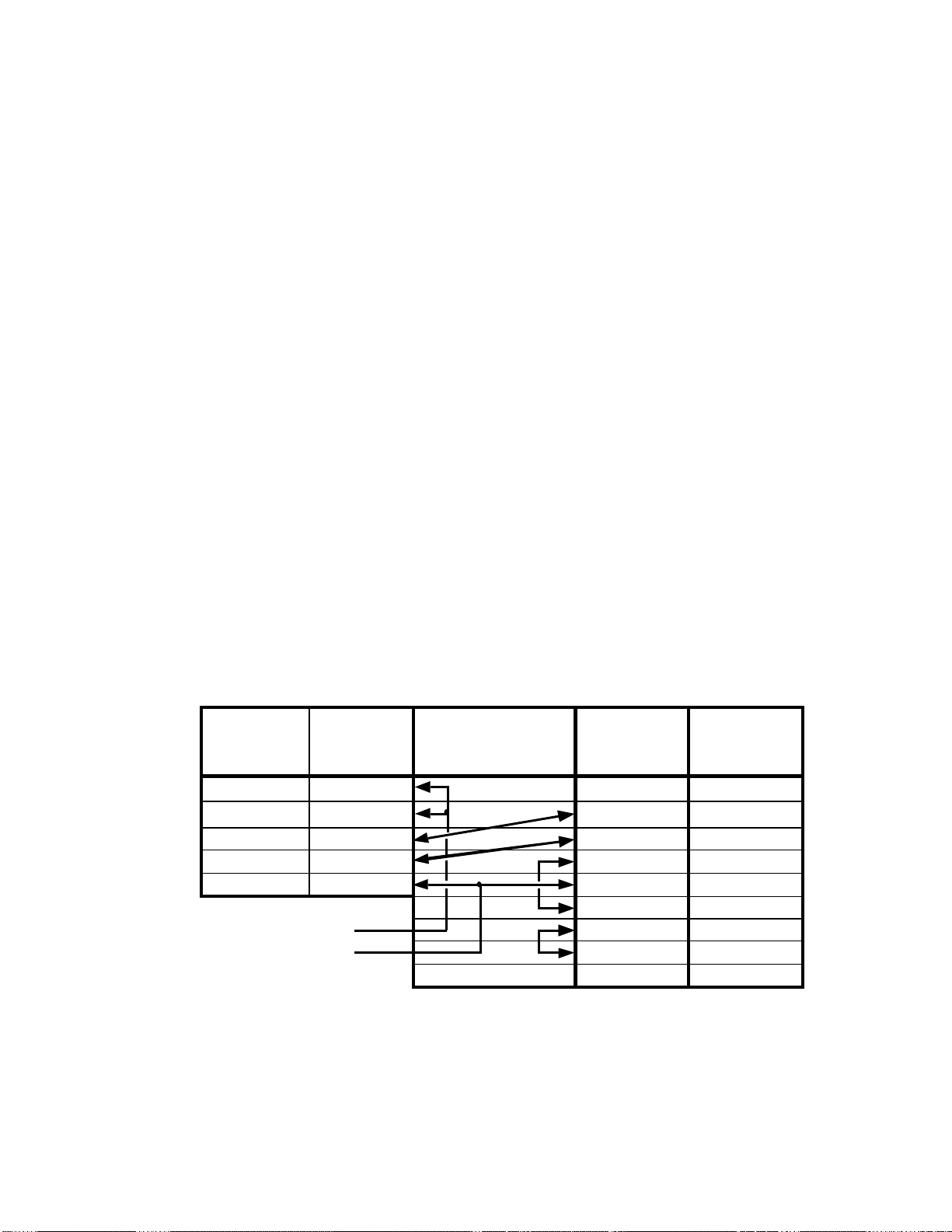

9. HOST RS 232 COMMANDS

9.1 General Description

All command strings begin with a “:”as shown and end with [CR] (not shown)

[CR] = ASCII carriage return character, 0DH.

[LF] = ASCII line feed character, 0AH.

<sh> = high digit of 8 bit hexadecimal checksum

<sl> = low digit of 8 bit hexadecimal checksum

Mode : Polling mode

Auto Send Mode (default)

Configuration –Saved in EEPROM.

9.2 UCIMAG Configuration Commands

:Bx - Change Baud rate x=3-> 9600, x=4->19200

:EtB - Enable/disable track reading 't' where t = 1 to 3 b=0 means disable, b=1 means enable

:Xb - Read direction, if b=0 forward, if b=1 reverse

:Ab - Auto clear bit, if b=0 disable, if b=1 enable

if Autoclear = 1, UCIMAG will automatically clear track buffers after sending track data,

user will NOT be able to poll data again.

if Autoclear = 0, data will remain in buffer until track clear command is sent.

:Sb - Auto send bit, if b=0 disable, if b=1 enable

if Autosend = 1, UCIMAG will automatically send track data as soon as card has been swiped,

user does not have to poll data.

:Nb - Auto notify bit, if b=0 disable, if b=1 enable