NATIONAL

TAPE

RECORDER

SERVICE

MANUAL

aT

Sica

Say

NEY

MODEL

RQ-152S

A.C

D.C

2

SOURCE

TAPE

RECORDER

CONTENTS

SPECIFICATIONS

i

v'e.

cs

cess

ves

cnstids

cesietidusstuatsedned

tasougsiedvuue

cre

cronvestgeesastadanss

PARTS

LOCATION.

ssessdcewciacitenedieineedavietewed

soigdacseateasadvecdoss

sa

sasectens

diese

BLOCK

DIAGRAM

OF

ELECTRICAL

CIRCUITS

........csccccescecsseneeesensonees

DISASSEMBLY

INSTRUCTION

uu...

cece

cee

eee

cee

ee

eee

eee

e

ne

nee

teen

ee

eeneneees

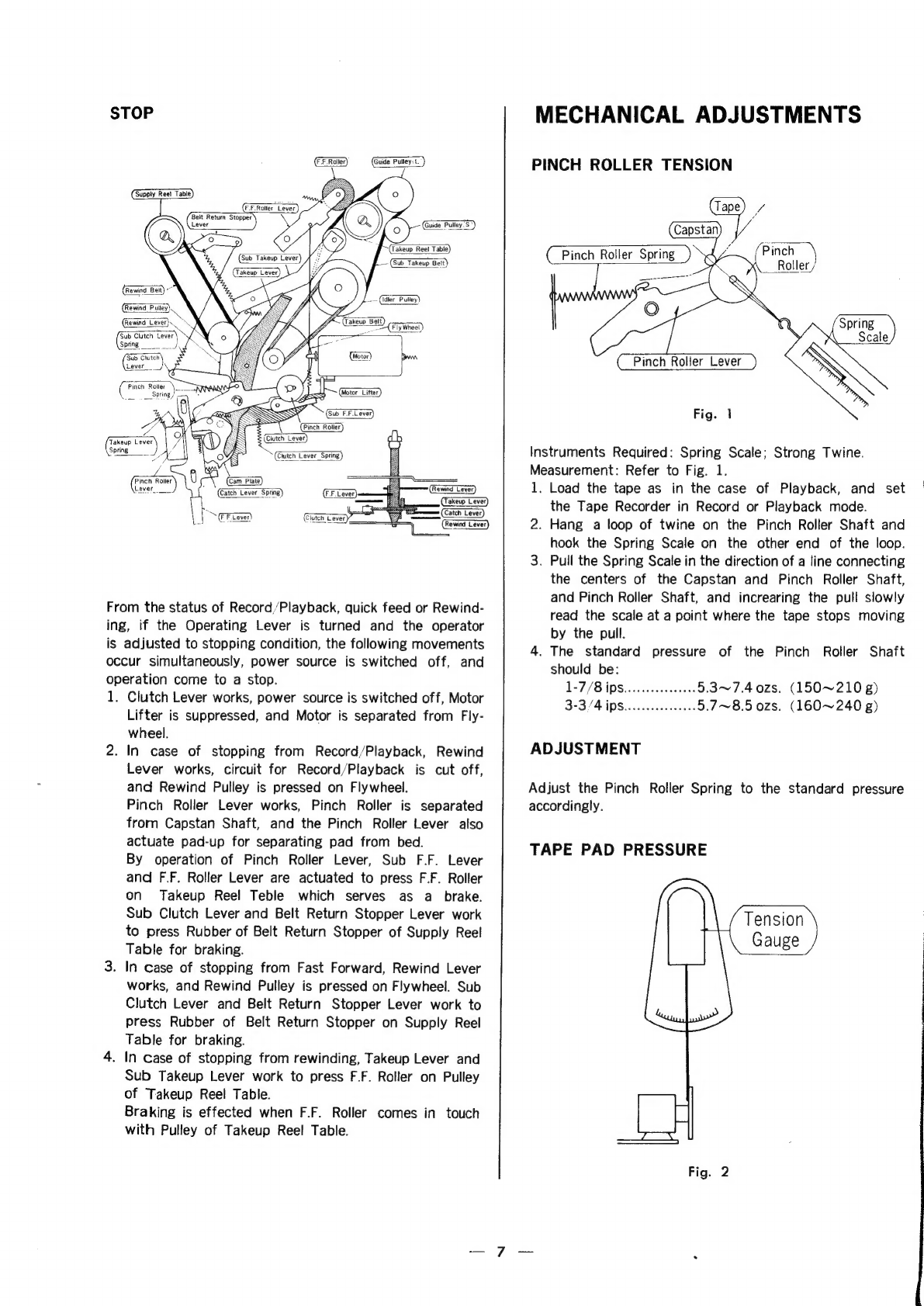

MECHANICAL

OPERATING

CONTROLS.

...........

0c:

ccecee

cee

ce

esse

ee

een ene

ee

een eee

TAPE

TRANSPORT

OPERATION

cicarcsacsncat

an

tavewuinsia

shaehieadwan

ena

aeduuanceate

MECHANICAL

ADJUSTMENTS.

.........

0c

cece

ccecee

eee

reece

aeeneeeeeene

nee

eenee

snes

AMPLIFIER

ADJUSTMENTS?

sus

seiveies

densatatmdsneniaaevetads

anata

ded

eotieeteiyaasse

TROUBLE:

“SHOOTING

“GUIDE.

sic

caitoutiancodsimavantectasina

rt

dvtananazsantaeices

REPLACEMENT

PARTS

ELISE

si

ecuviveciiiiiniceedeavelsveanth

bedaaes

sonacdeeedeasegas

CIRCUIT

BOARD

-sisccuctwcnitacdtodiaw

pani

<isda

staan

sta

Debesaa

eu

nidseeadecelisbeeutaeiye

CABINET

;PARTS

a:

cvs

teheemadattaiosttaeeievivads

eters

bsaes

i

aduarudscpenealiate

EXPLODES

VIEWS.

seistitate

scissors

etn

acs

tuatiiaails

cde

oh oe

galls

saith

de

semana

hamuanses¥

WIRING

CONNECTION

DIAGRAM

.............:eceecse

eee cen

eee

ee

tet

eeeaee

nse

eueueenes

SCHEMATIC

CIRCUIT

DIAGRAM:

\aiscs

trad

vesaisian

Gatien

gh

alvackainn

paveclan

eaves

PLECTRICAL

PARIS

LOCATION

tes.icdisane

nouetaestsa

ta

aanvigs

ea

aeeectesaas

ACCESSORIES

©

serene

coccinea

va

torsisdadebadtekoctengheatesanad

ate

cna

Lnter

nw

aeetdat

COMPONENT

PACKING

® 3

occseentt

ats

deol

sa

cen

tosYeaat

Sealine

vaevaailes

ditect

sta

tiaekas

MATSUSHITA

ELECTRIC

JAPAN