NATIONAL

TAPE

RECORDER

SERVICE

MANUAL

Sea

ase

ae

eae

rGsicat

a

eee

7

MODEL

RQ-152S8

A.C D.C

2

SOURCE

TAPE

RECORDER

CONTENTS

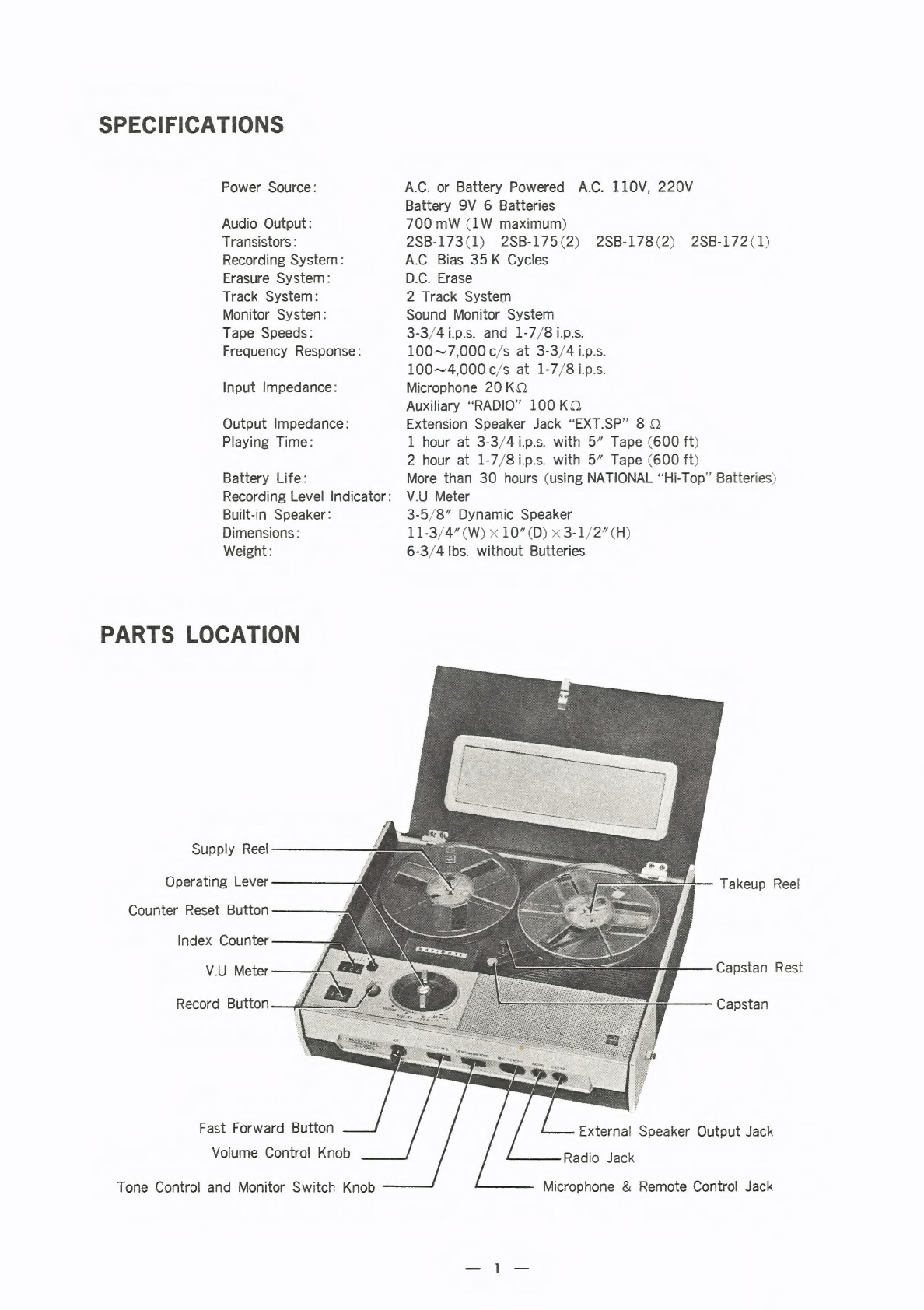

SPECIFICATIONS:

a2c2.roseen

tcc

cnien

crnets:

asaen

eure

coi

ae

uatinentscensnouresenmnsaeisess

PARTS

LOCATION

xtacsesecces

cess

cconsesremensents

usa

saescncenenemslansinminamedetesn

cc

BLOCK

DIAGRAM

OF

ELECTRICAL

CIRCUITS

........-.eeeeesee

eee

eee

eee

eee

eee

ees

DISASSEMBLY]

INSTRUCTION)

sizccses-tecssnnssccunomcesscrecenonsienemmecenesses

se

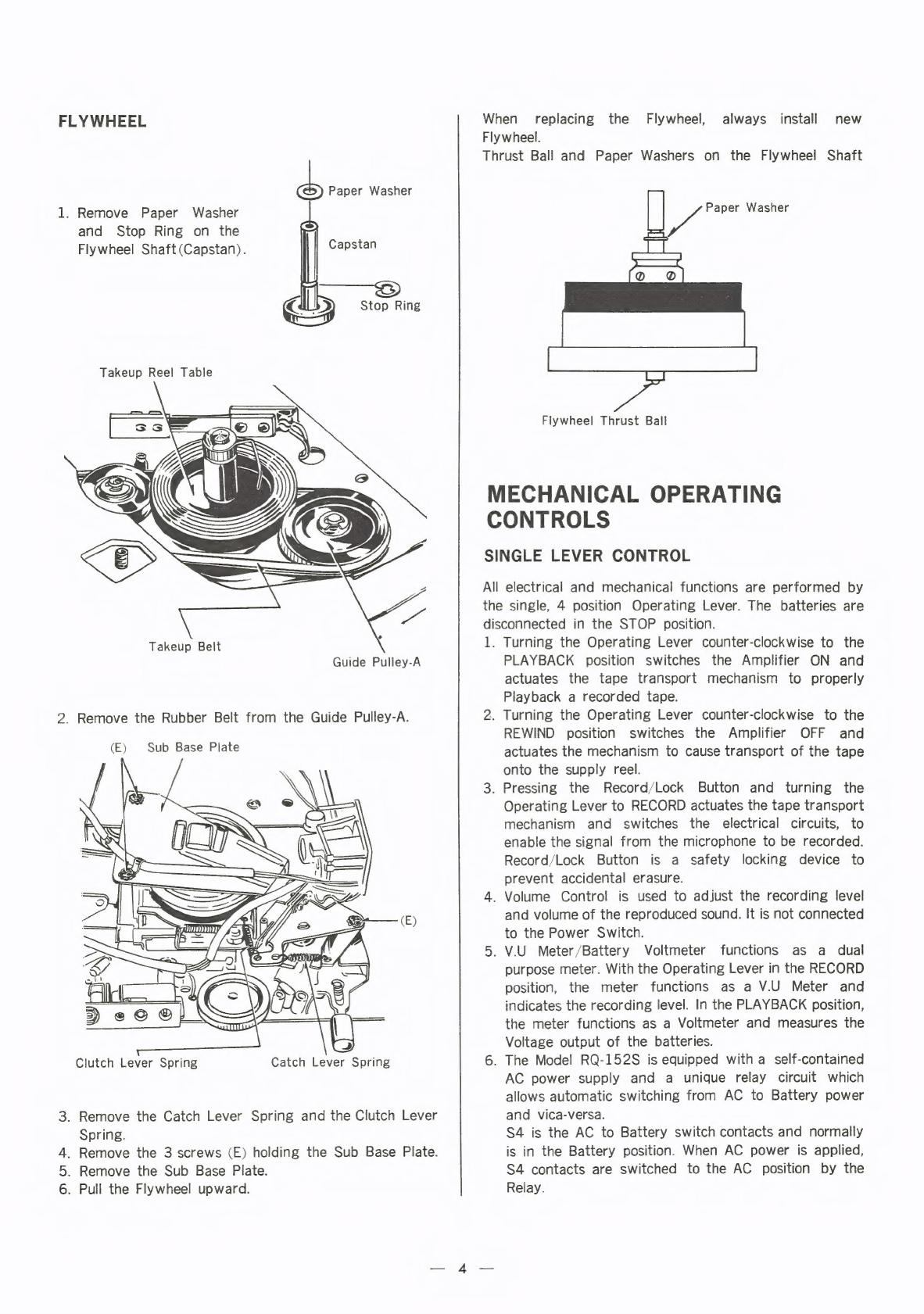

MECHANICAL

OPERATING

CONTROLG.............::ccecee

eee

eeecee

tence

eens

nee

een

ens

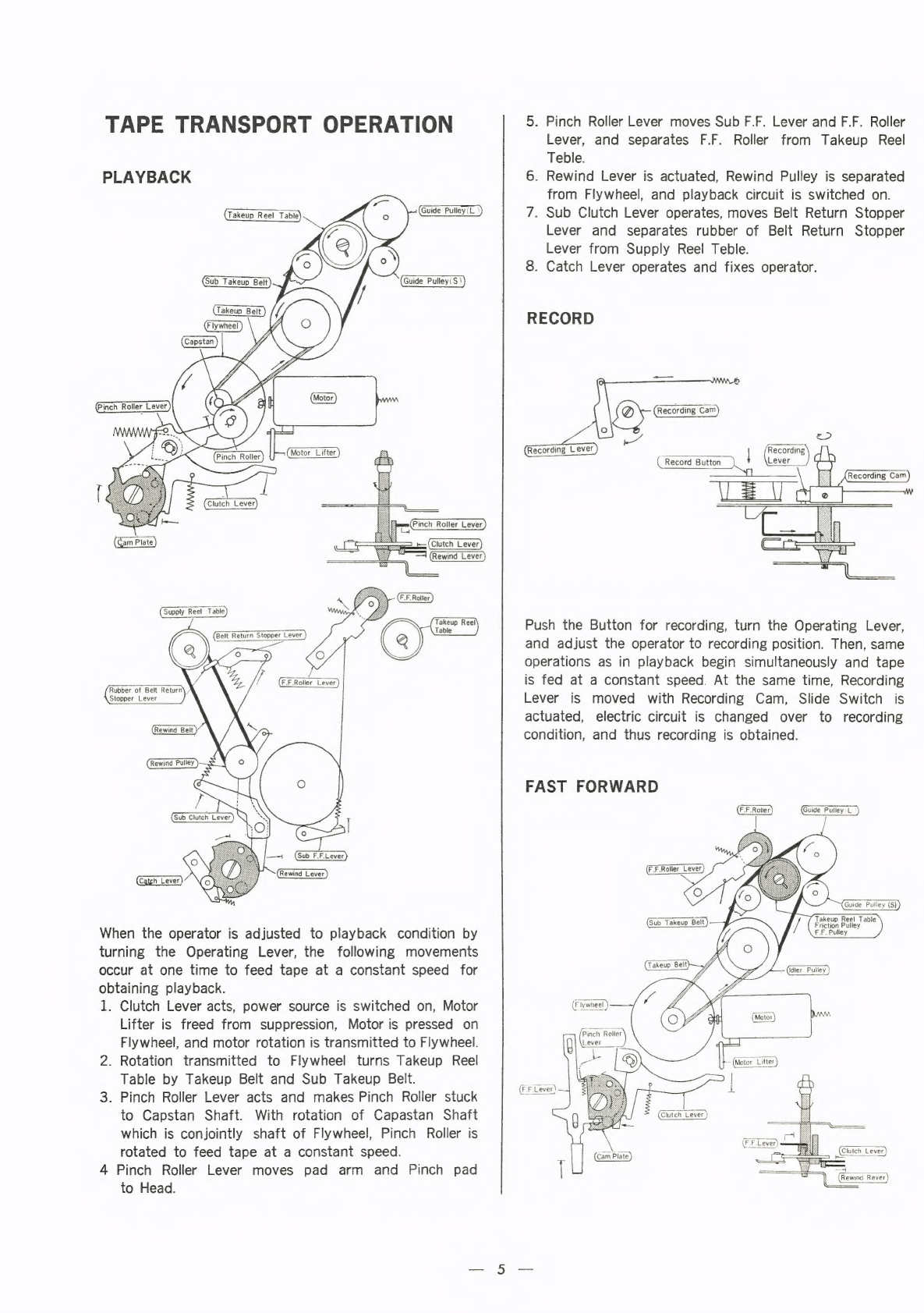

TAPE

TRANSPORT

OPERATION:

eticcescuss.crcore

esuacioscsssnsesanascinrenecencnss

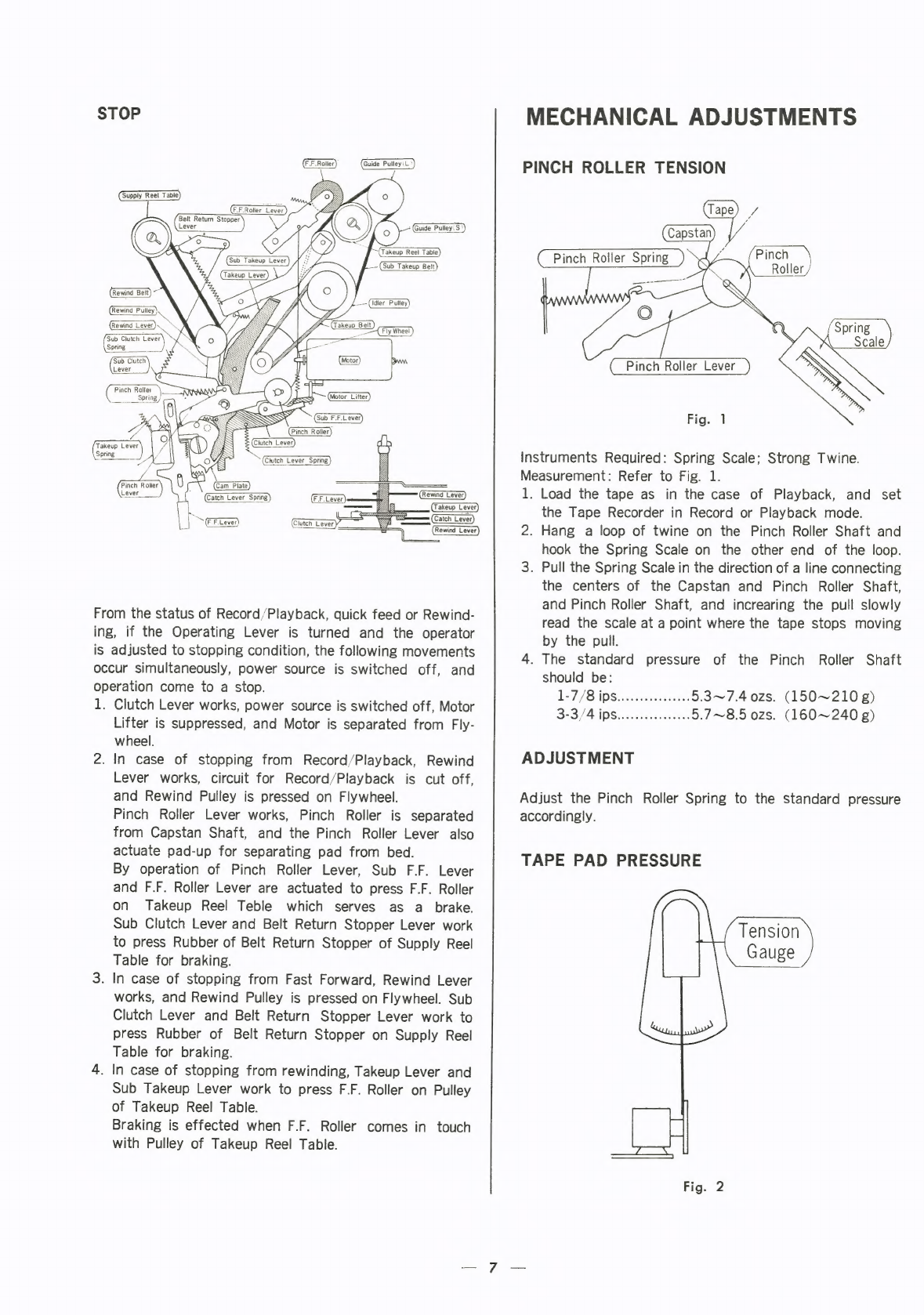

MECHANICAL

ADJUSTMENTS)

ann.

socacsceces

cnsscsnaneccstearereesentctinecererssr

anes

AMPLIFIER

ADJUSTMENTS

05.4

-ler-ciscenessssaciymossuesncnoscacmemnseoreenrtaiaecois:

TROUBLE

“SHOOTING:

GUIDE.

-.cca-crens

ccc

ceeanenceacanesbecaeaeuemenenenceneanee

REPLACEMENT

PARES

LISI

c2ec.c5iee.s2-c:csesecscnsn

ssasseennece

sss

seeeeamee

ree

stese

CIRCUIT

ABOARD

wees

ecco

secrecccanesancecnicea

ee

aanssea:

a

cslgansosusow

anacus

vseeeeviemmaines

GABINEN:

PARTSic-ceececaescct

strcess

ete

n

eace

sec

acenunia

swan

gscueee-manecienare

sevietsesen

EXPLODED

VIEWS:

ccc

csececee

us

otaecer

cnteeu

neice

ace

cacosameeesuie

mana

ara

euenmeneencsees

WIRING

CONNECTION

DIAGRAM

.............:.sccccnseeeeseeeeeeee

tea

eeeoeeecesunens

SCHEMATIG

‘CIRCUIT

DIAGRAM)

cizs.ae

ese

sosceccecac

ties

Sos

coca

ectonecen

estes

oecsien’

ELECTRICAL

PARTS:

LOCATION

sisecnt

siocivcseccesasesa.n

se

oceeecmemeceneneecenneess

AGGESSORIES),

Secccneseesooace

to

semencectsceeuns

sens

cates

ceniccatecieueunagiscsscee

COMPONENTEPAGKING

sxe

tosses

eens

tte

eens

enere

te

ememnae

se

colecetaaetar

ers

MATSUSHITA

ELECTRIC

JAPAN