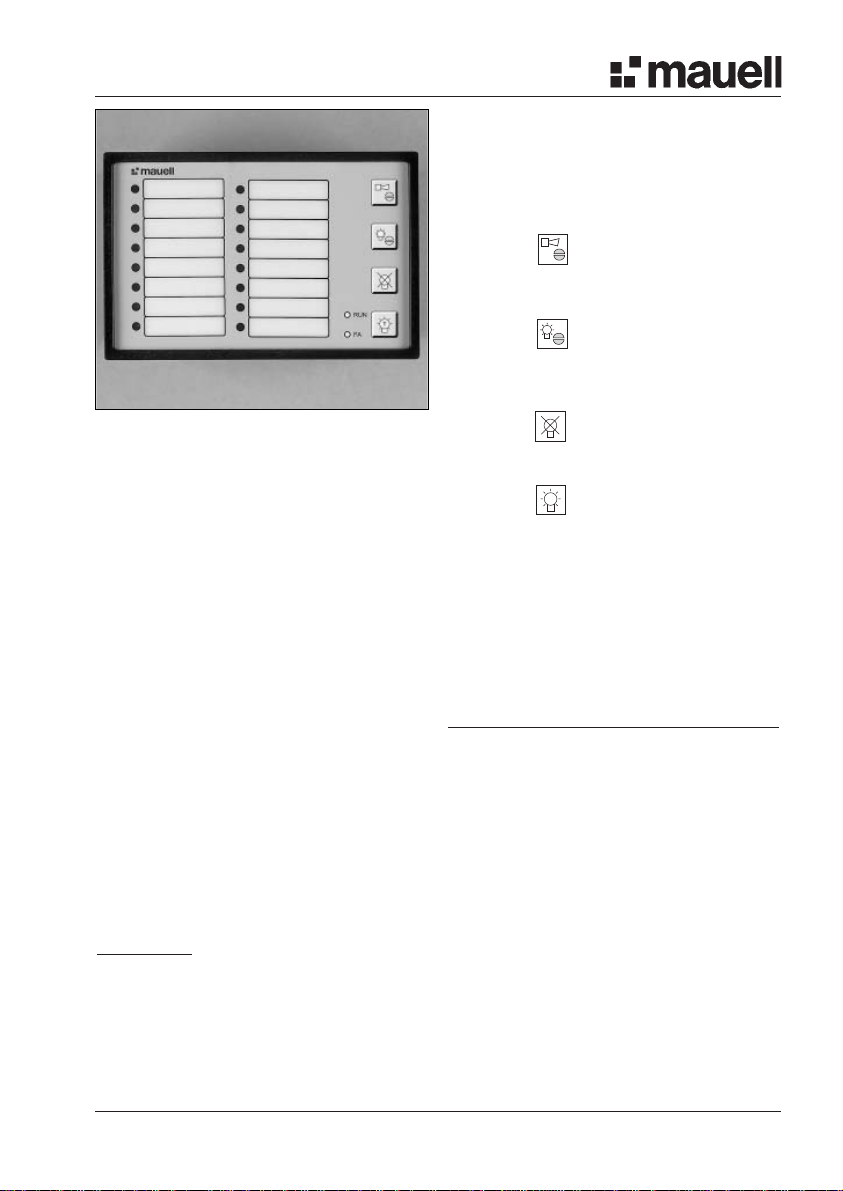

ME30 infobox connect

4infobox connect

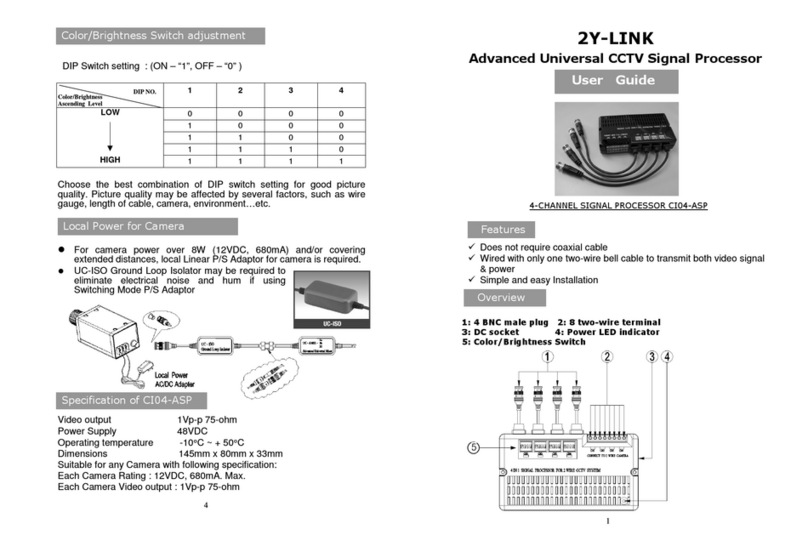

Terminal Assignment

Plug-in Pin Designation Meaning

connector

X01 1 UV(+) Supply voltage (positive terminal at DC)

2UV(-) Supply voltage (negative terminal at DC)

3ERDE Supply voltage Earth connection

X02 1 UH+ Emergency supply voltage, positive terminal

2UH- Emergency supply voltage, negative terminal

3HQ External pushb. input Horn acknowledgement

4Q External pushb. input Message acknowledgement

5LÖ External pushb. input Delete message

6LT External pushb. input Lamp test

X11 1 to 9 ME (+) Message input Contact supply

Group 1 (positive terminal at DC)

X11 (at 1 RA 1 Group 1 Message transmission relay contact 1

optional to

relay 8 RA 8 Group 1 Message transmission relay contact 8

output) 9 RA W Group 1 Message transmission relay contact Root contact

X12 1 ME 1 Group 1 Message input 1 (positive terminal at DC)

to

8ME 8 Group 1 Message input 8 (positive terminal at DC)

9ME (-) Group 1 Message inputs Group root (negative term. at DC)

X13 1 MR-Ö NC contact Annunciator relay output (*1)

2MR-S NO contact Annunciator relay output (*1)

3W Relay root contact

4MR-Ö NC contact Annunciator relay output (*2)

5MR-S NO contact Annunciator relay output (*2)

X21 1 to 9 ME(+) Group 2 Message inputs Contact supply

X21 (opt.) 1 to 9 RA 9 to RA16 Group 2 Message transmission relay contacts

X22 1 to 9 ME 9 to ME 16 Group 2 Message inputs

X23 1 to 5 MR Group 2 Annunciator relay outputs (*3)

X31 1 to 9 ME(+) Group 3 Message inputs Contact supply

X31 (option) 1 to 9 RA 17 to RA 24 Group 3 Message transmission relay contacts

X32 1 to 9 ME 17 to ME 24 Group 3 Message inputs

X33 1 to 5 MR Group 3 Annunciator relay outputs (*3)

X41 1 to 9 ME(+) Group 4 Message inputs Contact supply

X41 (option) 1 to 9 RA 25 to RA 32 Group 4 Message transmission relay contacts

X42 1 to 9 ME 25 to ME 32 Group 4 Message inputs

X43 1 to 5 MR Group 4 Annunciator relay outputs (*3)

X51 1 to 9 ME(+) Group 5 Message inputs Contact supply

X51 (option) 1 to 9 RA 33 to RA 40 Group 5 Message transmission relay contacts

X52 1 to 9 ME 33 to ME 40 Group 5 Message inputs

X53 1 to 5 MR Group 5 Annunciator relay outputs (*3)