Smokehouse MAUTING Junior Date:

1.7.2006

Worked out:

Fila Petr

Checked by:

Bielak Antonin Ing.

Approved by:

Bielak Antonin Ing.

Version No: 3 Page:

2of 22

Instruction manual

CONTENT:

1. INTRODUCTION......................................................................................................................................... 3

1.1. Usage ................................................................................................................................................... 3

2. GENERAL INSTRUCTIONS....................................................................................................................... 3

2.1. Safety................................................................................................................................................... 3

2.2. Symbol specifications.......................................................................................................................... 3

2.3. Safety regulations –organization measures......................................................................................... 4

2.4. Safety regulations –protective instruments ......................................................................................... 4

2.5. Safety regulations –device operator.................................................................................................... 4

2.6. Safety regulations –work with smoke generator................................................................................. 5

2.7. Safety regulations by maintainanace, cleaning and troubleshooting.................................................... 5

2.8. Warning labels placement.................................................................................................................... 6

2.9. List of safety devices and their role ..................................................................................................... 6

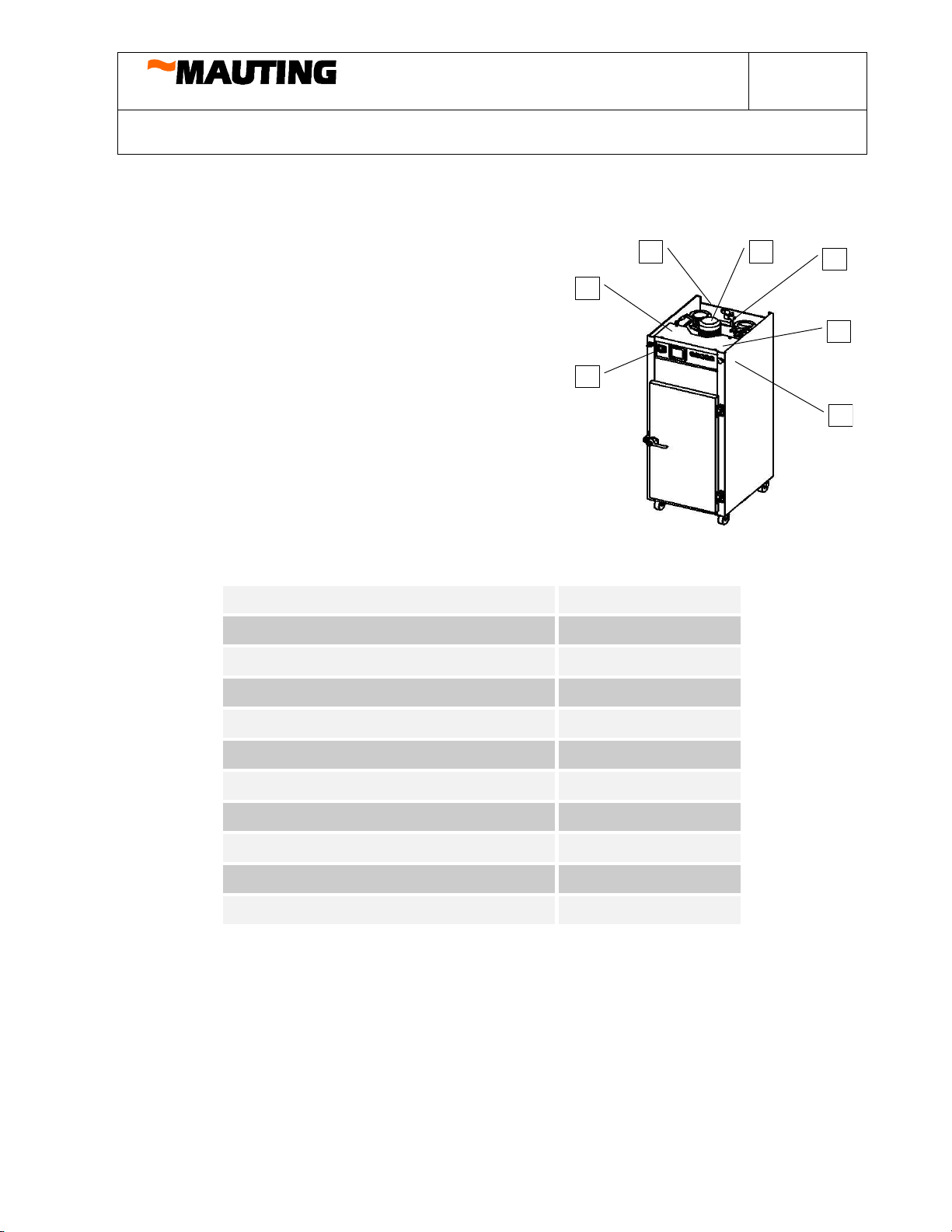

3. TECHNICAL DESCRIPTION...................................................................................................................... 7

3.1. Operation conditions............................................................................................................................ 7

3.2. Technical parameters ........................................................................................................................... 7

3.3. Description........................................................................................................................................... 7

3.4. Material.............................................................................................................................................. 10

3.5. Operator ............................................................................................................................................. 11

4. INSTALLATION OF CHAMBER ............................................................................................................. 14

5. ACCEPTANCE, DELIVERY..................................................................................................................... 15

6. ORDERING ................................................................................................................................................ 15

7. PACKAGING, TRANSPORTATION, STORAGE.................................................................................... 16

8. CLEANING................................................................................................................................................. 16

8.1. Technological process of chamber cleaning ...................................................................................... 16

8.2. Technological process of smoke generator cleaning.......................................................................... 16

9. MAINTAINACE AND TROUBLESHOOTING........................................................................................ 17

9.1. Periodic service and inspection schedule........................................................................................... 17

10. MALFUNCTIONS AND THEIR REPAIRS ......................................................................................... 18

11. SPARE PART LIST ............................................................................................................................... 20

12. GUARANTEE........................................................................................................................................ 20

13. REGULATIONS AND STANDARDS.................................................................................................. 21

14. PICTURES AND APPENDIX:.............................................................................................................. 21

15. REMARKS............................................................................................................................................. 22