9

CHAPTER 1 – INTRODUCTION

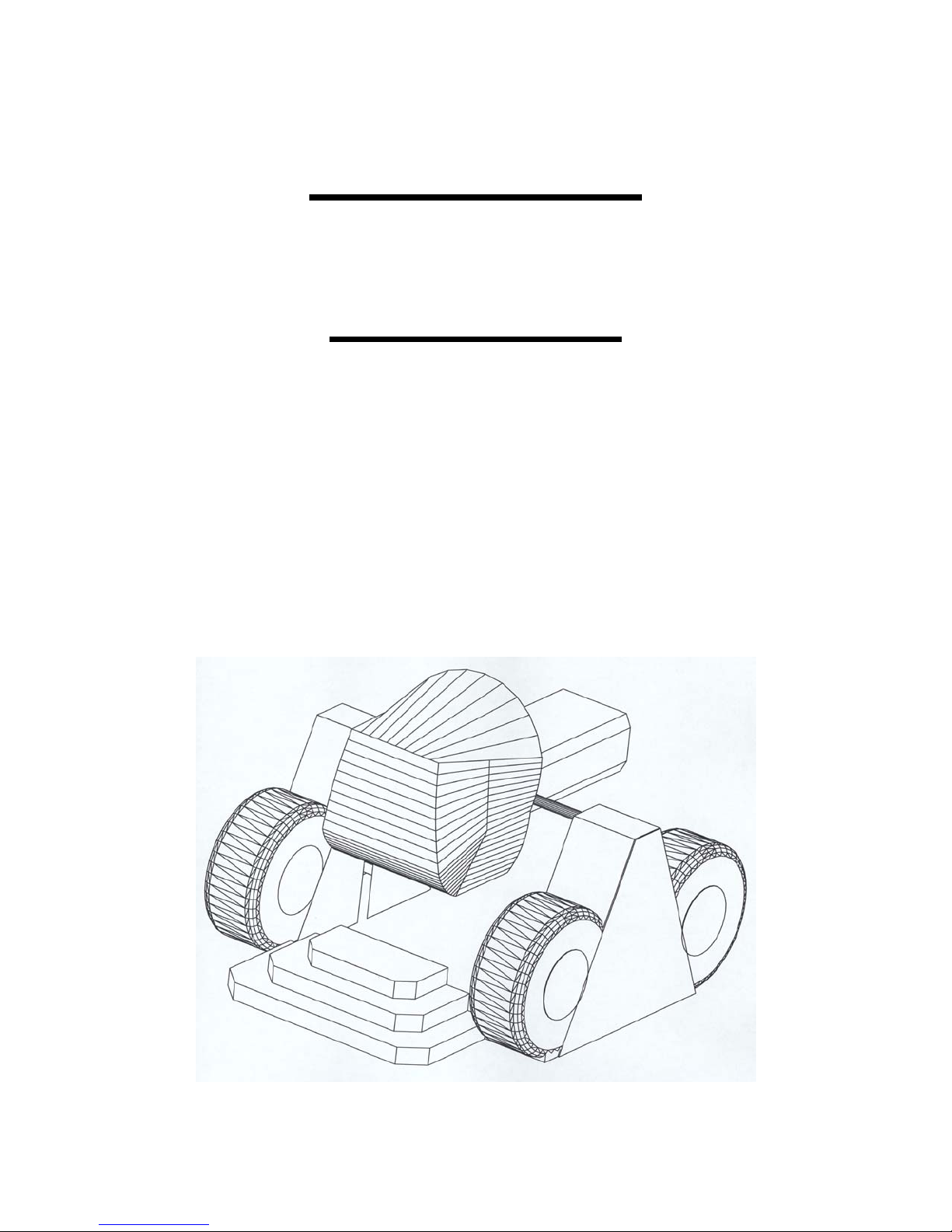

1-1 Introduction to the MT3000

Welcome!! And thank you on your purchase of the MT3000 Monster Truck Simulator. The MT3000 is

the only full motion interactive networked experience of it’s kind. This is a dual seat monster truck

simulator based on a virtual reality environment with a full 360 degree, 2 axis motion platform. The

experience time can be varied according to patron demand while the standard time set is 6 minutes. You

can select from two track layouts thus making your ride as unique as possible.

1-2 Overview of the MT3000

The MT3000 is a computer driven monster truck simulator that provides a realistic monster truck driving

track.

1-3 Overview of the Ride Selection System

The customer can select their own track layout. There are two specific tracks that the

simulator can run on and they are: Monster truck arena, a series of jumps and bumps in a

confined space and the island road race, a open space environment with all the pitfalls of

real cross country driving. Whenever the terrain warrants a motion of the monster truck

it will emulate it to a degree of two motion flips. The (2) passenger cockpit is equipped

with a huge 58” projection screen and a pulse pounding surround sound system. Once

the cockpit is closed and locked, the passengers embark on a six minute (variable by

operator) default driving experience without the hassle of city traffic. A ride they will

never forget.

1-4 Specific Ride Information

This section has been included in your manual to give you specific and detailed information about the

MT3000 Monster Truck Simulator. This information complies with the ASTM 698-94 standard (American

Society for Testing and Materials) which governs Physical Information to be provided for Amusement

Rides and Devices.

Ride Speed: Pitch Axis - 90 Degrees per second (15RPM)

Roll Axis - 90 Degrees per second (15 RPM)

Direction of Travel: Pitch – 360 Degrees

Roll – 360 Degrees

Vertical axis (Y-axis)

Maximum passenger capacity by weight per passenger position: 250 lbs.

Maximum passenger capacity by weight per the total device: 500 lbs.

Maximum passenger capacity by number per the total device: 2

Duration of passenger exposure: Up to six minutes

Passenger weight distribution: Maximum Unbalance – 100 lbs.

Environmental restrictions: Stable Environment – Temperatures less than 80°F,

Humidity less than 60%