Maxim Integrated Page 6 of 15

1.2 Accelerometer

For best results, it is recommended that accelerometer data be provided to the MAX32664A.

SpO2 calculation requires a resting condition, and the algorithm uses accelerometer data to detect

excessive motion. In such a condition, computation is paused, and the user is informed with a

motion flag.

A sensor hub accelerometer can be integrated through the I2C port of the MAX32664A. In this

case, the required driver for KX122 is already included. The user only needs to follow the

reference schematics to connect the accelerometer and enable it before starting the algorithm,

as described later in this document.

Alternatively, a host-side accelerometer can be used. In order to use the host-side accelerometer:

1. The host should start the accelerometer just before enabling the algorithm to maximize

the initial synchronization between the PPG and accelerometer samples. However,

accelerometer samples collected prior to receiving the confirmation of the algorithm

enable I2C command should be discarded.

2. The host is required to use a 3-axis accelerometer at a 100Hz sampling rate. If a higher

sampling rate is chosen, samples should be decimated to be synchronized with a 10ms

PPG sampling time.

3. The host must queue five accelerometer samples and feed them at the same time to the

MAX32664A using the commands shown in Table 2. The period of feeding samples

should be 200ms. Because the sensor and the host accelerometer use different clock

sources, exact synchronization between them is not possible.

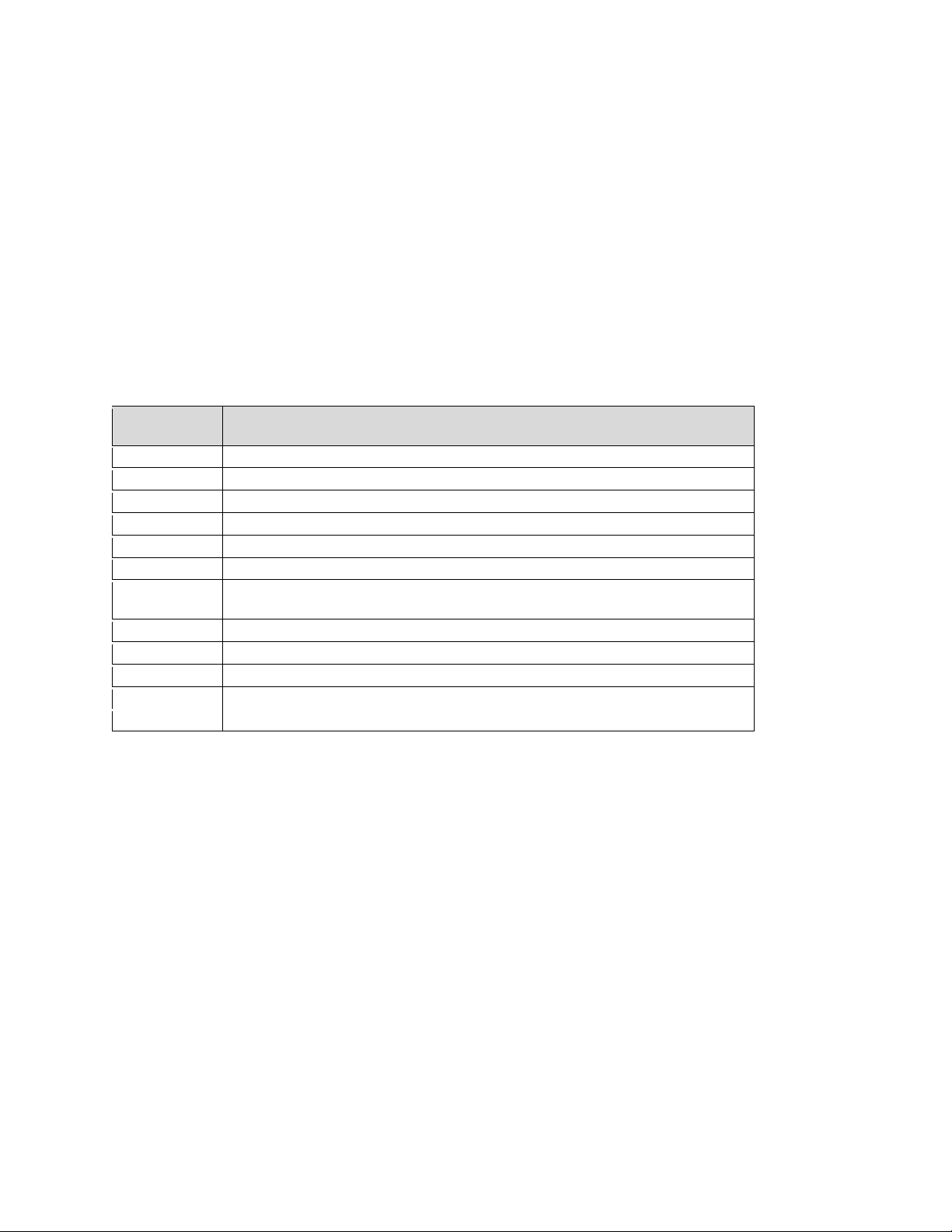

Table 2. Host-Side Accelerometer—Sending Data to the MAX32664A

HOST COMMAND

(HEX) DESCRIPTION

RESPONSE

DESCRIPTION

Enable the host accelerometer.

AA 13 00 04 Read the sensor sample size for

the accelerometer (optional). AB 00 06

number of bytes per

The following should be executed periodically at 200ms:

AA 14 00 [Sample

1 values] …

[Sample N values]

Write data to the input FIFO of the

sensor hub.

Each sample has three 2-byte

integer values for X, Y, and Z in

milli-g.

AB 00 Success

AA 00 00 Read the sensor hub status. AB 00 00

Success; sensor hub

not busy