9

TM

SAFETY GUIDELINES

• Always maintain the compressor the compressor properly to avoid internal

corrosion and possible failure.

• Release all pressure within the compressor slowly, as the dust and debris is harmful

and affect human health.

• Keep the exterior of the compressor dry, clean, and free from oil and grease.

Always use a clean cloth for cleaning. Never use brake fluids, gasoline, petroleum-

based products, or any strong solvents to clean the compressor to reduce the risk of

deterioration of the plastic enclosure.

• When servicing the compressor, use only replacement parts of same specification

to avoid risk of injury and equipment damage.

• Drain out the moisture from the tank completely after each day’s use to prevent

corrosion on the inside of the tank.

• Before using the compressor, check for damaged parts, misalignment or binding

of moving parts, broken parts, and any other condition that affects the operation.

The damaged parts should be properly repaired or replaced only by a qualified

electrician. The repaired part should be checked carefully to ensure that it operates

properly and performs its intended function.

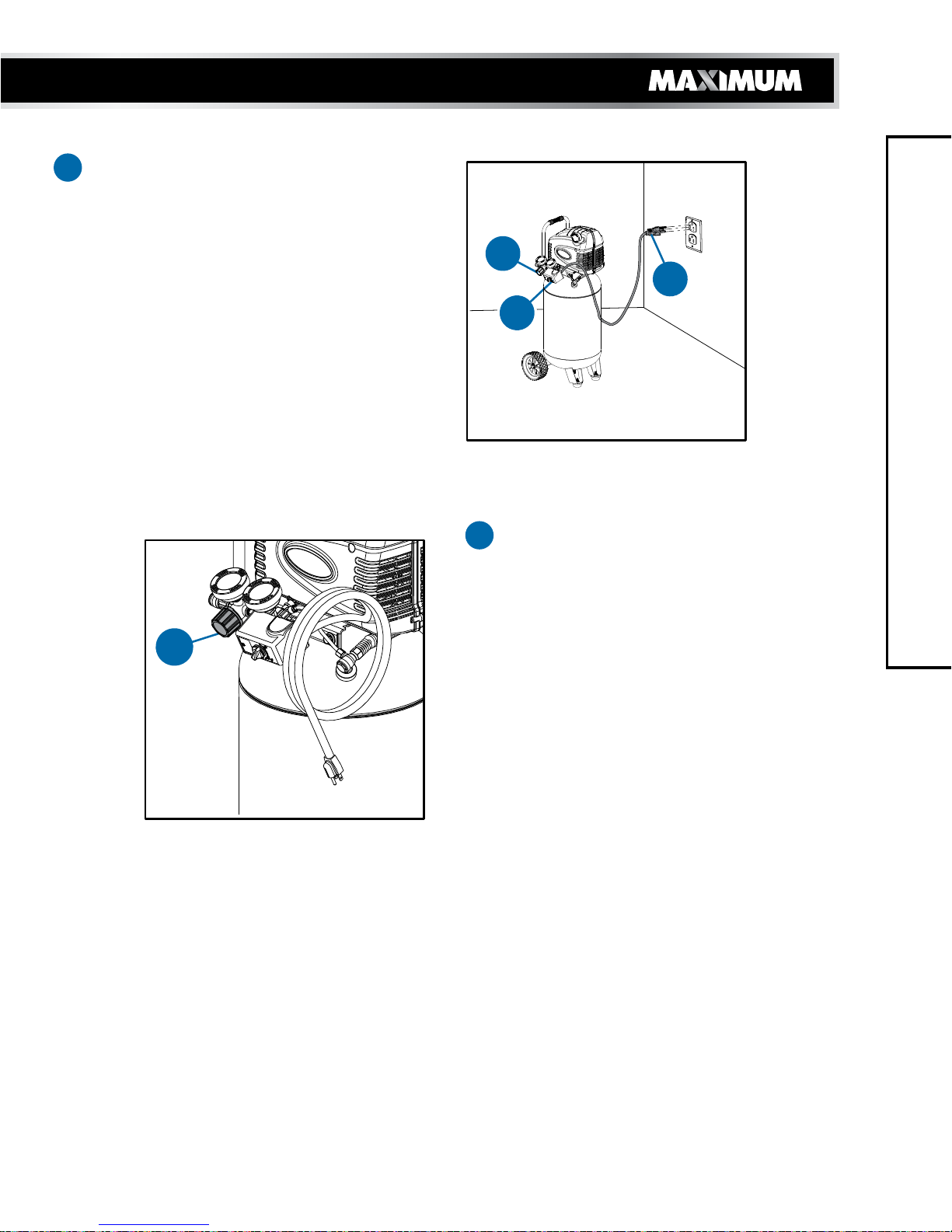

• Use the proper extension cord. Make sure to use an extension cord that is suitable

to carry the current required by the air tool. A wire of 12 gauge size is recommended

for an extension cord of length 50’ (15 m) or less. It is not recommended to use a

cord exceeding 100’ (30 m). If in doubt, use the next heavier gauge. An undersized

cord will cause a drop in line voltage, resulting in loss of power and overheating of

the air tool.

• Ensure compressor is plugged into a circuit protected by a fuse or breaker.

• Inspect the air tank yearly for rust, pin holes, or other imperfections. Never weld or

drill holes in the air tank.

• Use safety glasses and ear protection. Wear safety glasses with side shields when

operating the tool and verify that others in the work area are also wearing safety

glasses. Safety glasses must conform to American National Standards Institute

(ANSI Z87.1) requirements and must provide protection from flying particles from

the front and the sides. Compressors are loud and the sound can cause hearing

damage. Always wear ear protection to help prevent hearing damage and loss.

Failure to comply may result in moderate injury.