11

SAFETY GUIDELINES

10

SAFETY GUIDELINES

ELECTRICAL SAFETY

GROUNDING INSTRUCTIONS:

In the event of a malfunction or breakdown, grounding provides a path of least

resistance for electric current to reduce the risk of electric shock. This tool is equipped

with an electric cord having an equipment-grounding conductor and a grounding plug.

The plug must be plugged into a matching outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the

outlet, have the proper outlet installed by a

qualified electrician. Improper connection of the

equipment-grounding conductor can result in a risk

of electric shock. The conductor with a green outer

surface, with or without yellow stripes, is the

equipment-grounding conductor. If repair or

replacement of the electric cord or plug is

necessary, do not connect the equipment-grounding

conductor to a live terminal.

Check with a qualified electrician or service

technician if the grounding instructions are not

completely understood, or if in doubt as to whether

the tool is properly grounded. Use only three-wire

extension cords that have three-prong grounding plugs and three-pole receptacles that

accept the tool's plug, as shown in Fig. 1. Repair or replace a damaged or worn cord

immediately.

GUIDELINES FOR USING EXTENSION CORDS:

• Make sure the extension cord is in good condition. When using an extension cord, be

sure to use one that is heavy enough to carry the current that your product will draw.

An undersized cord will cause a drop in line voltage, which will result in loss of power

and overheating. The table on the next page shows the correct size to be used

according to cord length and nameplate ampere rating. When in doubt, use the next

heavier gauge. The smaller the gauge number, the heavier the cord.

• Make sure your extension cord is properly wired and in good condition. Always

replace a damaged extension cord, or have it repaired by a qualified person before

using it. Protect your extension cords from sharp objects, excessive heat, and damp or

wet areas.

• Use a separate electrical circuit for your tools. This circuit must consist of not less than

#12 wire with a 20 A time-delayed fuse or a #14 wire with a 15 A time-delayed fuse.

Before connecting the motor to the power line, make sure the switch is in the OFF

position and the electric current is rated the same as the current stamped on the

motor nameplate. Running at a lower voltage will damage the motor.

• Use only extension cords that are intended for outdoor use. These extension cords are

identified by a marking "Acceptable for use with outdoor appliances; store indoors

while not in use." Use only extension cords having an electrical rating not less than the

rating of the product. Do not use damaged extension cords. Examine extension cord

before using and replace if damaged. Do not abuse extension cords and do not yank

on any cord to disconnect. Keep cord away from heat and sharp edges. Always

disconnect the extension cord from the receptacle before disconnecting the product

from the extension cord.

• WARNING – To reduce the risk of electrocution, keep all connections dry and off the

ground. Do not touch plug with wet hands.

CAUTION!

In all cases, verify that the outlet in question is properly

grounded. if you are not sure, have a licensed electrician

check the outlet.

WARNING!

• Use the proper extension cord. Make sure to use an

extension cord that is heavy enough to carry the current

required by the tool. An undersized cord will cause a

drop in line voltage, resulting in loss of power and

overheating of the tool.

• Use the extension cord only for intended purpose. Do

not pull the extension cord to remove it from the power

socket.

• This tool must be grounded while in use in order to

protect the operator from electric shock.

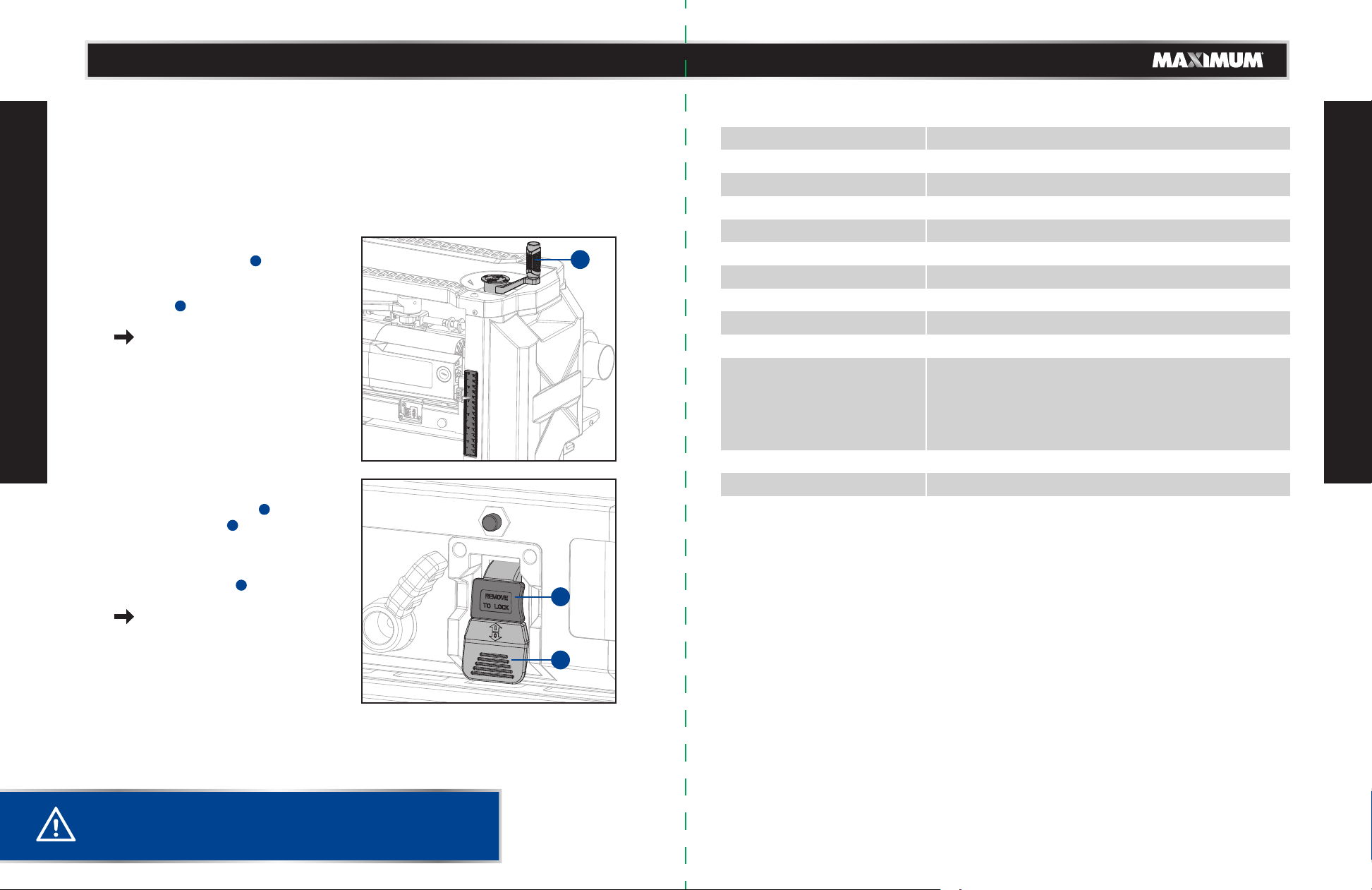

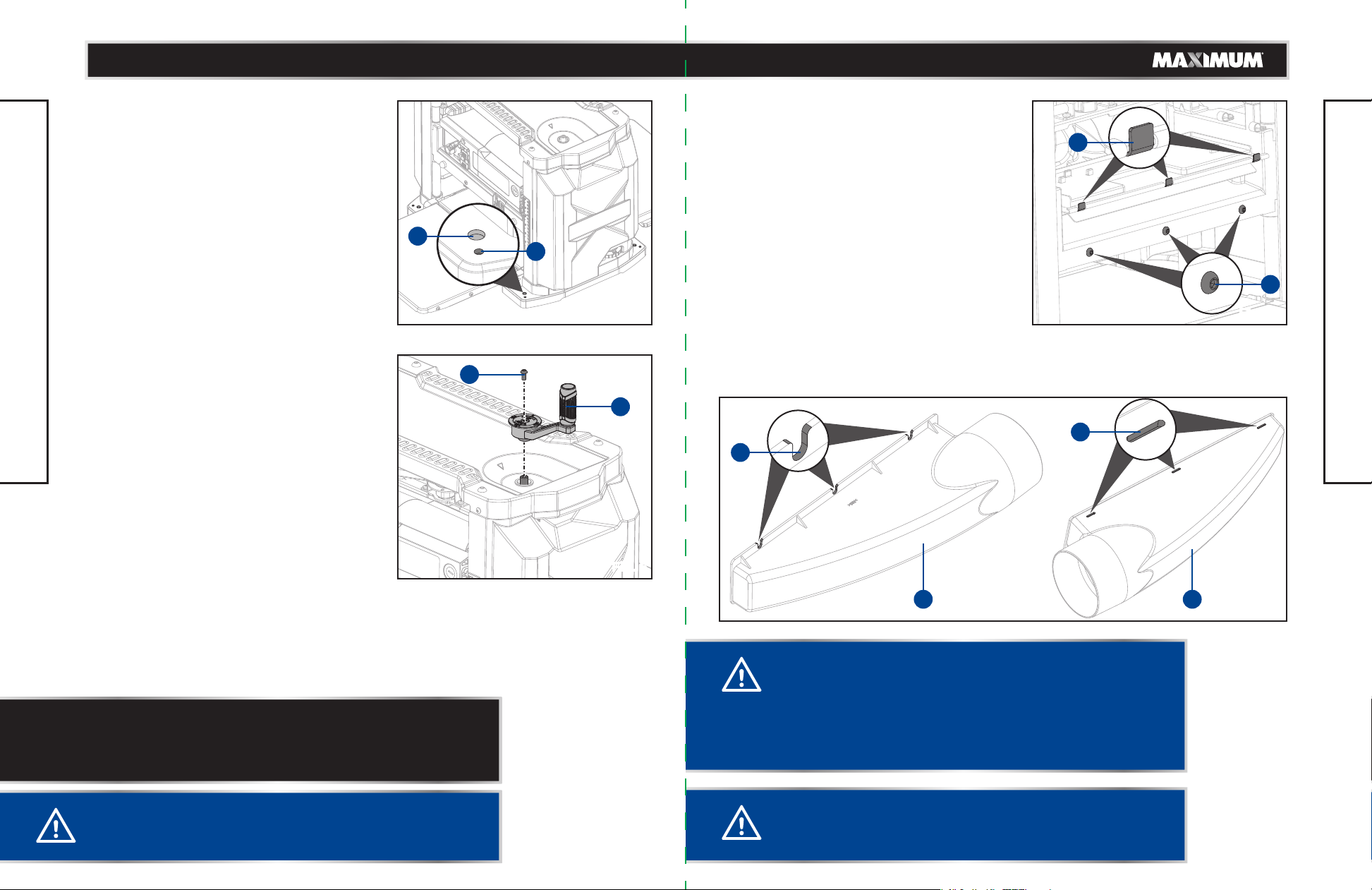

Fig. 1

Three-prong plug

Grounding prong

Properly grounded

outlet

NOTE: Recycle unwanted materials rather than disposing of

them as waste. Sort the tool and its components in specific

categories and take to the local recycling centre or dispose of

them in an environmentally safe way.

Danger! Keep hands away from blade.

model no. 055-6971-2 | contact us 1-888-670-6682

The tool is loud and the sound can cause hearing damage. Always wear

ear protection to help prevent hearing damage and loss. Failure to comply

may result in moderate injury.

USE DUST MASK:

Some dust created by sawing contains chemicals that are known to cause

cancer, birth defects or other reproductive harm. Some examples of these

chemicals come from lead-based paints; crystalline silica from bricks,

cement and other masonry products; and arsenic and chromium from

chemically treated lumber. To reduce exposure to these chemicals, work

in a well-ventilated area with approved safety equipment, such as dust

masks that are specially designed to filter out microscopic particles.