jbc SFR-B User manual

Solder Feeder for Automation

Ref. SFR-B

INSTRUCTION MANUAL

www.jbctools.com

Packing List

The following items are included:

Allen Key 1,5 mm ......... 1 unit

Ref. 0741610

Reel Support ................. 1 unit

Ref. 0024561

Solder Feeder for

Automation .................... 1 unit

Ref. SFR-B

Communications

Cable 3 m........................ 1 unit

Ref. 0024563

Spanner 10 mm............. 1 unit

Ref. 0017631

Allen Key 2,5 mm ......... 1 unit

R ef. 0 012574

Screws

DIN 912 M4x65.......... 2 units

Ref. 0024552

Screws

DIN 912 M4x20........ 2 units

Ref. 0921890

Manual ............................ 1 unit

Ref. 0024557

Insulator ........ 1 unit

Ref. 0024588

Allen Key 3 mm ......... 1 unit

Ref. 0013609

Screws

DIN 7991 M4x10........ 1 unit

Ref. 0490180

2

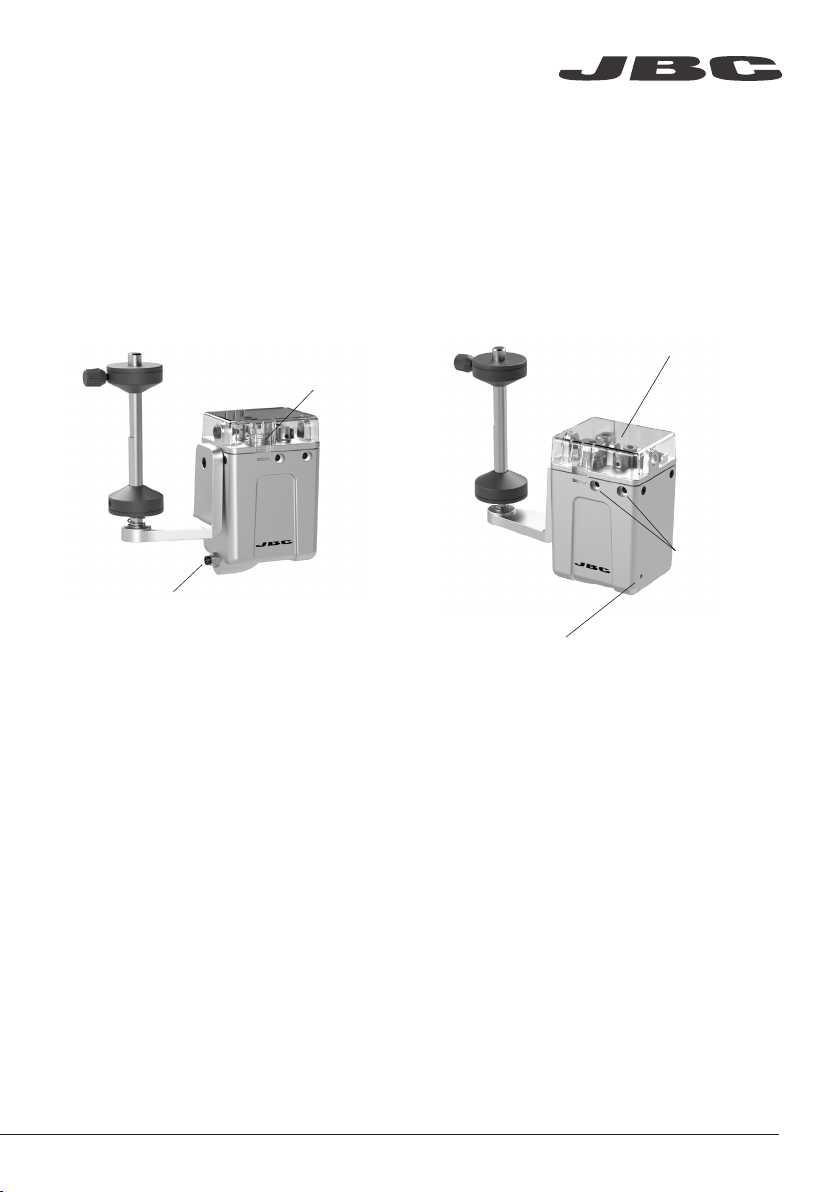

Features

Communications and Power

Connector

LED Indicator:

· Blue: device powered

· Green: device working

· Red blinking: error, no solder wire

or device is blocked

Assembling

holes

The SFR Solder Feeder works together with one of the different GSFR Guide Kits, available for the various solder

wire diameters, with or without solder wire perforation. GSFR kits are sold separately.

Drag mechanism

Lid with

push tabs

www.jbctools.com

3

1 3

5

2 4

Transmitted data - Grey cable

Optional:

Pedal activation by

relay or digital output

Ground - Blue cable

Brown cable

Black cable

Received data - White cable

Female DB9

Connector

5

4

9

8

7

6

3

2

1

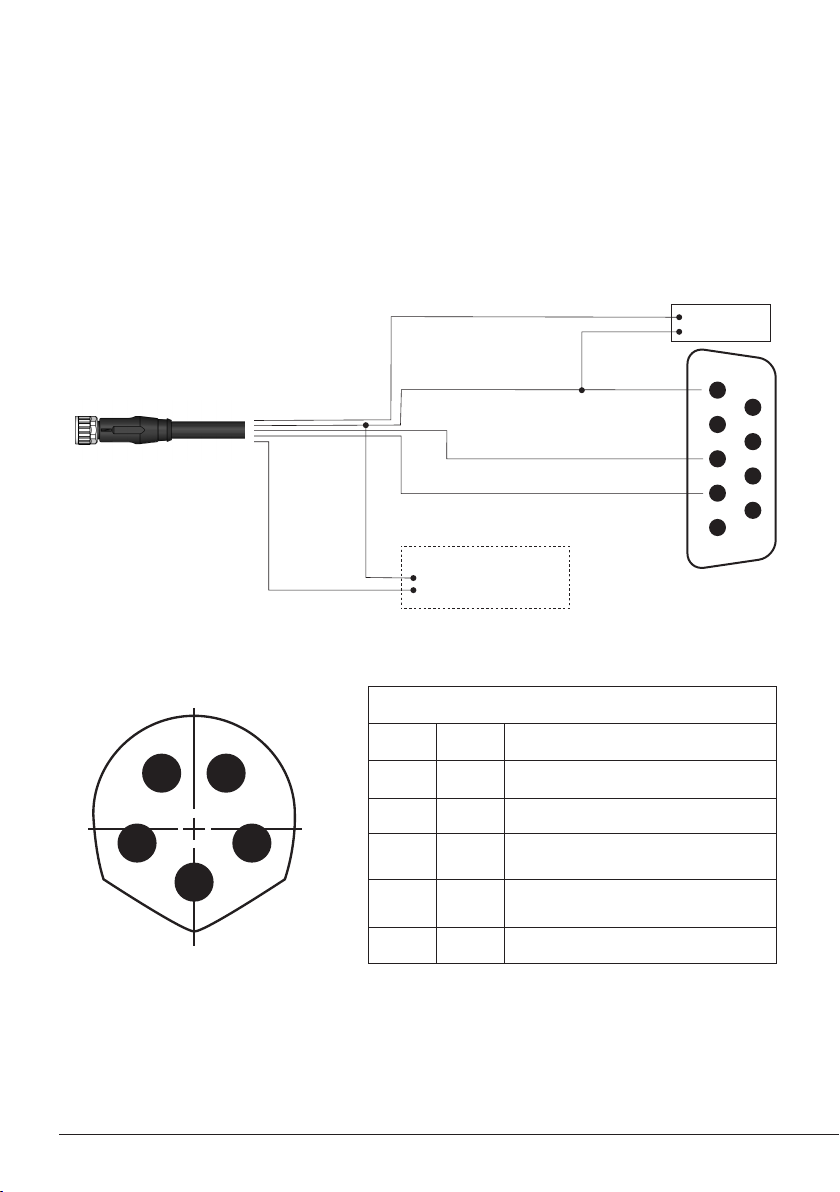

Connection

- The SFR unit can be connected to a PLC by a five-pin Communications Cable (Ref. 0020261).

- Connect the cables to the corresponding pins to match your PLC connection. To comunicate with

a computer use a DB9 female connector.

- Download the Robot Communication Protocol at www.jbctools.com

Communications Cable

Ref. 0020261

For detailed information about pin distribution see following table:

Front view

SFR Communications Connector

Pin Distribution

Pin Color Description

1 Brown Power supply input:

24Vdc (±5%). 1.5 A current required

2 White Serial input: RS232 RX

3 Blue Common reference:

GND for RS232 and witch

4 Black Switch input: 0V or 24V to start feeding.

Leave it open to stop

5 Grey Serial output: RS232 TX

V+ 24 Vdc

V- 1.5 A

4

1

3

2

4

1

3

2

4

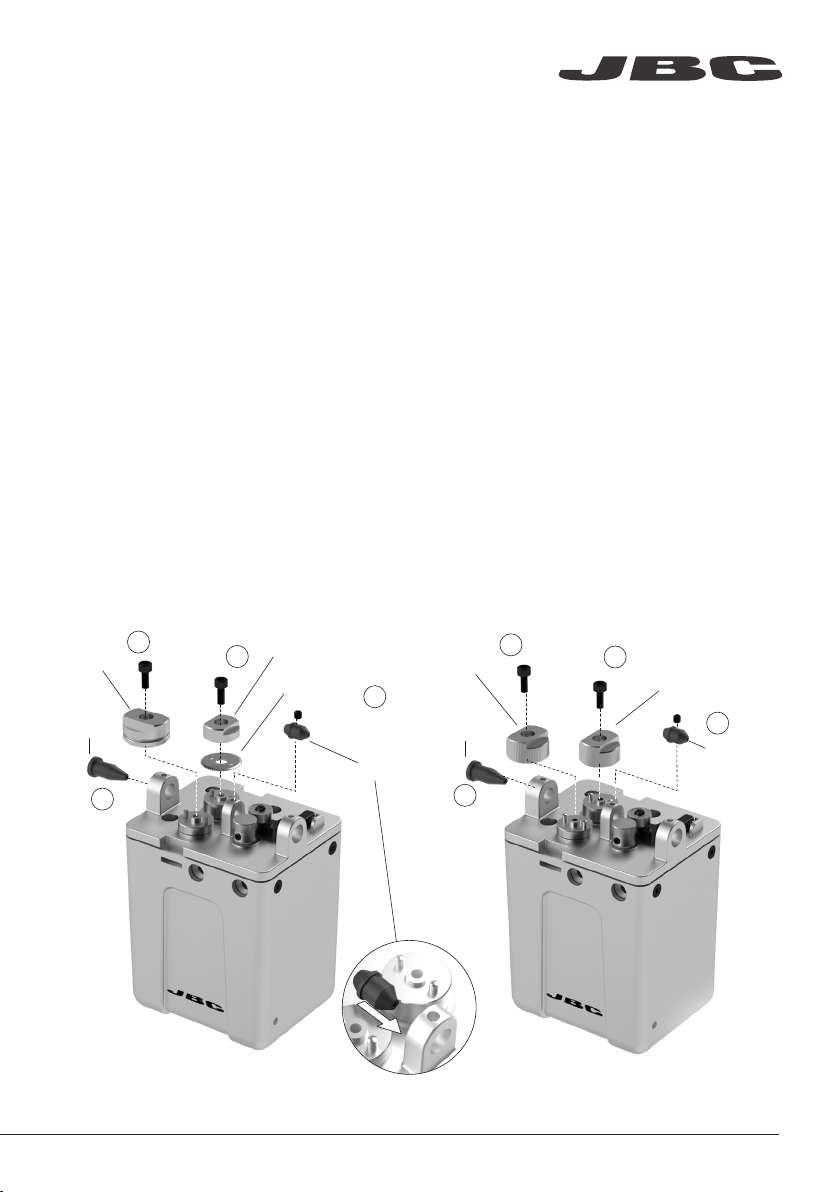

Assembly: GSFR* Wheels to SFR

For this operation, disconnect the device, and dismantle the cover by pushing the tabs at both sides

of the lid. Use the allen key and the spanner to assemble the following components.

1. Insert the Intermediate Nozzle until its collar rests against the housing and tighten the screw.

2. Assemble the Guide Wheel and tighten the screw. If you use a Guide Kit without Solder

Wire Perforation assemble the Support Wheel.

Attention: Always use the correct wheel set for each wire thickness.

3. If you have a Guide Kit with Solder Wire Perforation assemble the Blade first, then mount the

Blade Clamp onto the same axis and tighten the screw. If you use a Guide Kit without Solder

Wire Perforation, assemble the Traction wheel.

Caution: handle the blade carefully to avoid injury.

4. Insert the Inlet Nozzle into the hole and tighten the screw.

GSFR* with Solder Wire Perforation GSFR* without Solder Wire Perforation

Blade

Blade Clamp

Inlet

Nozzle

Inlet

Nozzle

Guide

Wheel Traction

Wheel

Support

Wheel

Inter.

Nozzle

Inter.

Nozzle

*Not included, sold separately

www.jbctools.com

5

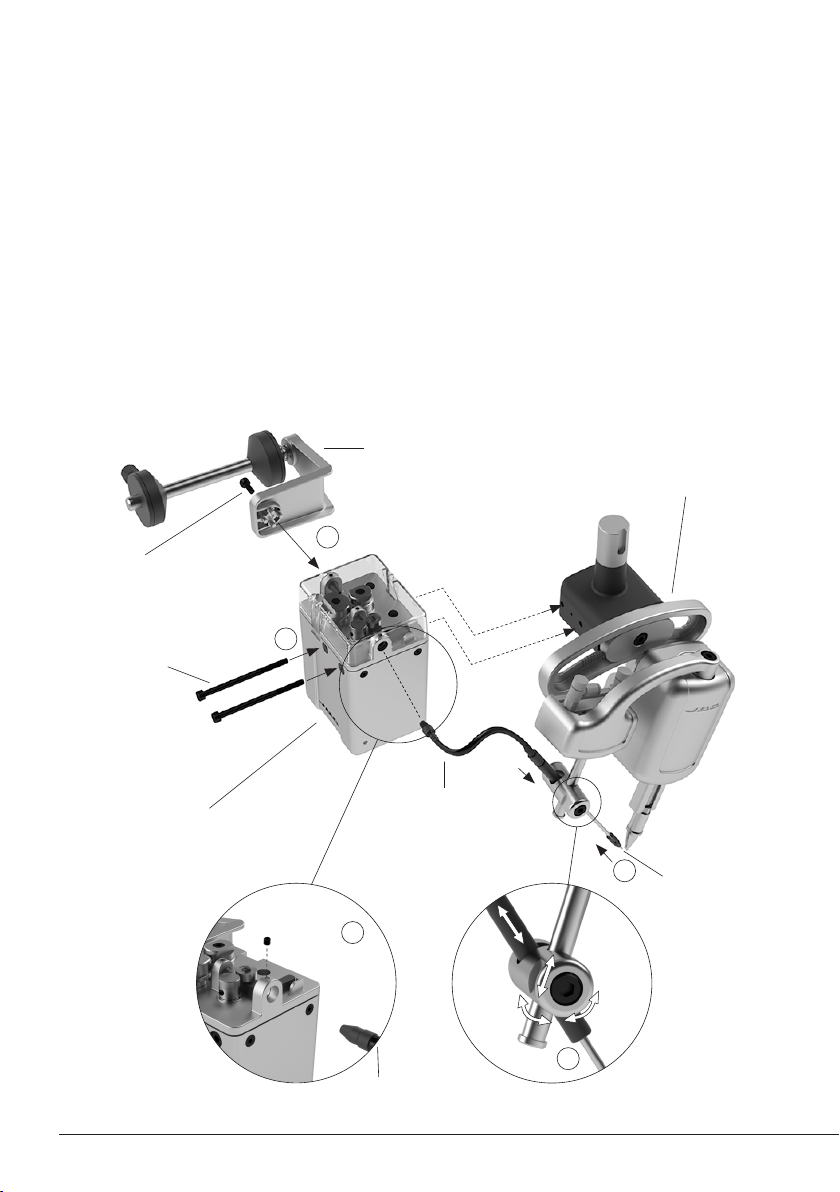

4

2

1

3

5

1. Assemble the SFR to the TRA with the screws.

2. Assemble the GSFR Guide Tube to the TRA and adjust its position, then tighten the screw.

3. Assemble the Outlet Nozzle onto the Dispensing Tube.

4. Assemble the GSFR Bushing into the SFR hole and tighten the screw.

5. Attach the Reel Support to the SFR with its screws.

Assembly: SFR to TRA*

Solder Feeder

for Automation

Ref. SFR-B

GSFR Guide Tube*

Soldering Head

for Automation*

Ref. RBA-B

Reel Support

Ref. 0024561

Screws

Ref. 0024552

Screw

Ref. 0490180

GSFR Bushing*

*Not included, sold separately

Outlet Nozzle*

The guide position

can be adjusted in

angle, height and

length

6

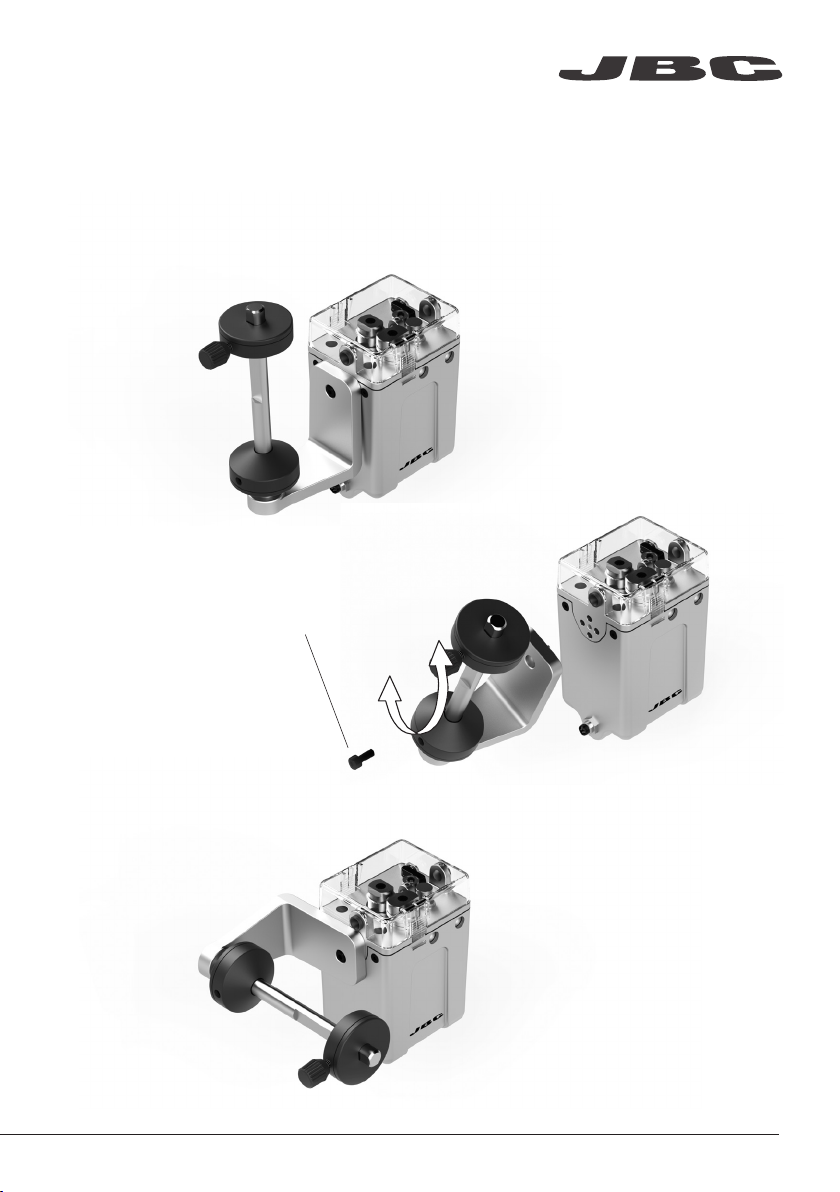

Assembly: Reel support positions

The reel support can be installed both vertically and horizontally to match your preferences.

Unscrew the bolt using a 3mm allen key and set the support as desired.

Tighteen the bolt to lock the support.

Loosen the bolt

completely before

repositioning the

support.

Vertical Reel

Support

Horizontal Reel

Support

www.jbctools.com

7

Assembly: SFR independent from TRA*

Screws

Ref. 0014954

Solder Feeder

for Automation

Ref. SFR-B

Insulator

Ref. 0021713

Screws

Ref. 0921890

If mounting SFR independently from TRA, the Electrical Insulator is required.

Assemble the Insulator to your device with its screws, followed by the SFR to The insulator with its

screws.

The Electrical Insulator must be assembled for the tool to work properly.

*Not included, sold separately

Do not use the SFR without insulator if it is mounted without the TRA.

8

Solder Wire Loading

The GSFR must be assembled previously.

1. Feed the Solder Wire into the Inlet Nozzle until it reaches the wheels.

2. Make sure the wire passes through the Intermediate Nozzle and enters into the Guide Tube.

Wire feeding is controlled by an external controller (Robot/PLC/Computer). See the Robot Commu-

nication Protocol for SFR unit at www.jbctools.com/jbcsoftware.html

Solder Wire

2

1

Wheels

Inlet

Nozzle

Guide

Tube

Intermediate

Nozzle

Intermediate

Nozzle

www.jbctools.com

9

Dimensions (Vertical Reel Suport)

Solder Wire Reel dimensions: max. lenght 80mm (3.2 in), max. diameter 80mm (3.2 in), max. weight 1 kg (2.2 lb).

mm

(in)

10

Table of contents