)

Max. torque ................................................................................................ 218 mNm

Max. permissible speed (restricted by Encoder) ..................................... 12000 rpm

Max. efficiency .................................................................................................. 70 %

Torque constant .................................................................................... 24.3 mNm/A

Speed constant ......................................................................................... 393 rpm/V

Speed / Torque gradient .................................................................... 20.6 rpm/mNm

Rotor inertia .............................................................................................. 21.9 gcm2

Axial play at axial load < 6 N ....................................................................... 0 mm

> 6 N .................................................................. 0.14 mm

Radial play ................................................................................................ preloaded

Max. axial load (dynamic) ................................................................................. 5.5 N

Max. force for press fits (static) ....................................................................... 100 N

Max. radial loading, 5 mm from flange .............................................................. 25 N

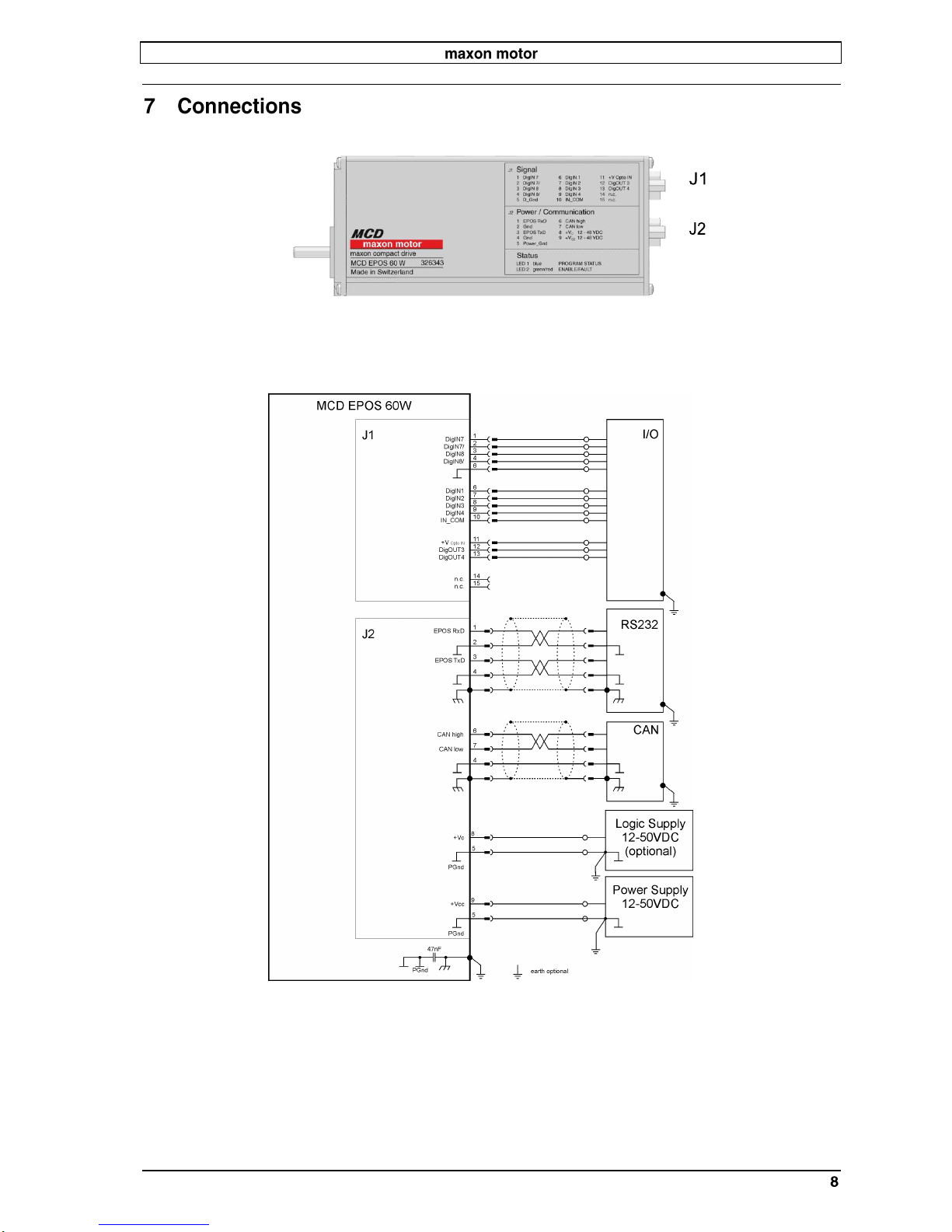

Power supply voltage VCC (Ripple < 10%) .......................................... 12 …50 VDC

Logic supply voltage VC(Ripple < 10%) (optional) ............................. 12 …50 VDC

Max. output voltage .................................................................................... 0.9 · VCC

Max. output current Imax ....................................................................................... 9 A

Continuous output current Icont ..................................... 2.6 A (Ta=25 °C, 5000 rpm)1)

Switching frequency ....................................................................................... 50 kHz

Max. efficiency .................................................................................................. 93 %

Sample rate PI - current controller ................................................................. 10 kHz

Sample rate PI - speed controller .................................................................... 1 kHz

Sample rate PID - positioning controller .......................................................... 1 kHz

Position resolution ............................................................................................ 0.09°

Position accuracy ..................................................................................... typical ± 1°

Position reproducibility ........................................................................ typical ± 0.09°

Hall sensor signals ................................. Hall sensor 1, Hall sensor 2, Hall sensor 3

Encoder signals .............................................................................. 1000 Increments

A, A\, B, B\, I, I\ (max. 200 KHz)

Digital input 1 (“General Purpose”) ........ opto-isolated ..................... +9 ... +24 VDC

Digital input 2 (“Home Switch”) .............. opto-isolated ..................... +9 ... +24 VDC

Digital input 3 (“Positive Limit Switch”) .. opto-isolated ..................... +9 ... +24 VDC

Digital input 4 (“Negative Limit Switch”) . opto-isolated ..................... +9 ... +24 VDC

Digital input 7 (“High Speed Command”) ............ line receiver EIA standard RS-422

Digital input 8 (“High Speed Command”) ............ line receiver EIA standard RS-422

+V Opto IN ...................................................................................... +12 …+24 VDC

Digital output 3 (“General Purpose”) ...... opto-isolated max. 24 VDC (IL< 350 mA)

Digital output 4 (“General Purpose”) ...... opto-isolated max. 24 VDC (IL< 350 mA)