maxon EC motor

2Document ID:: rel8710 EC-i30 IE

Edition: March 2019 Operating Manual

© 2019 maxon motor. Subject to change without prior notice.

Safety Guidelines

Qualified

personnel

Do not engage with any work unless you possess the necessary skills.

Legal

requirements

Observe any regulation applicable in the country and/or at the site of implementation with regard to

health and safety/accident prevention and/or environmental protection.

Make sure that all associated devices and components are installed according to local regulations.

Additional safety

equipment

Be aware that, by principle, an electronic apparatus can not be considered fail-safe. Therefore, you must

make sure that any machine/apparatus has been fitted with independent monitoring and safety equip-

ment. If the machine/apparatus should break down, if it is operated incorrectly, if the control unit breaks

down or if the cables break or get disconnected, etc., the complete drive system must return – and be

kept – in a safe operating mode.

Repairs Be aware that you are not entitled to perform any repair on components supplied by maxon motor.

Danger to life Touching live wires causes death or serious injuries!

• Consider any power cable as connected to live power, unless having proven the opposite!

• Make sure that neither end of cable is connected to live power!

• Make sure that power source cannot be engaged while work is in process!

• Obey lock-out/tag-out procedures!

• Make sure to securely lock any power engaging equipment against unintentional engagement

and tag it with your name!

Max. supply

voltage

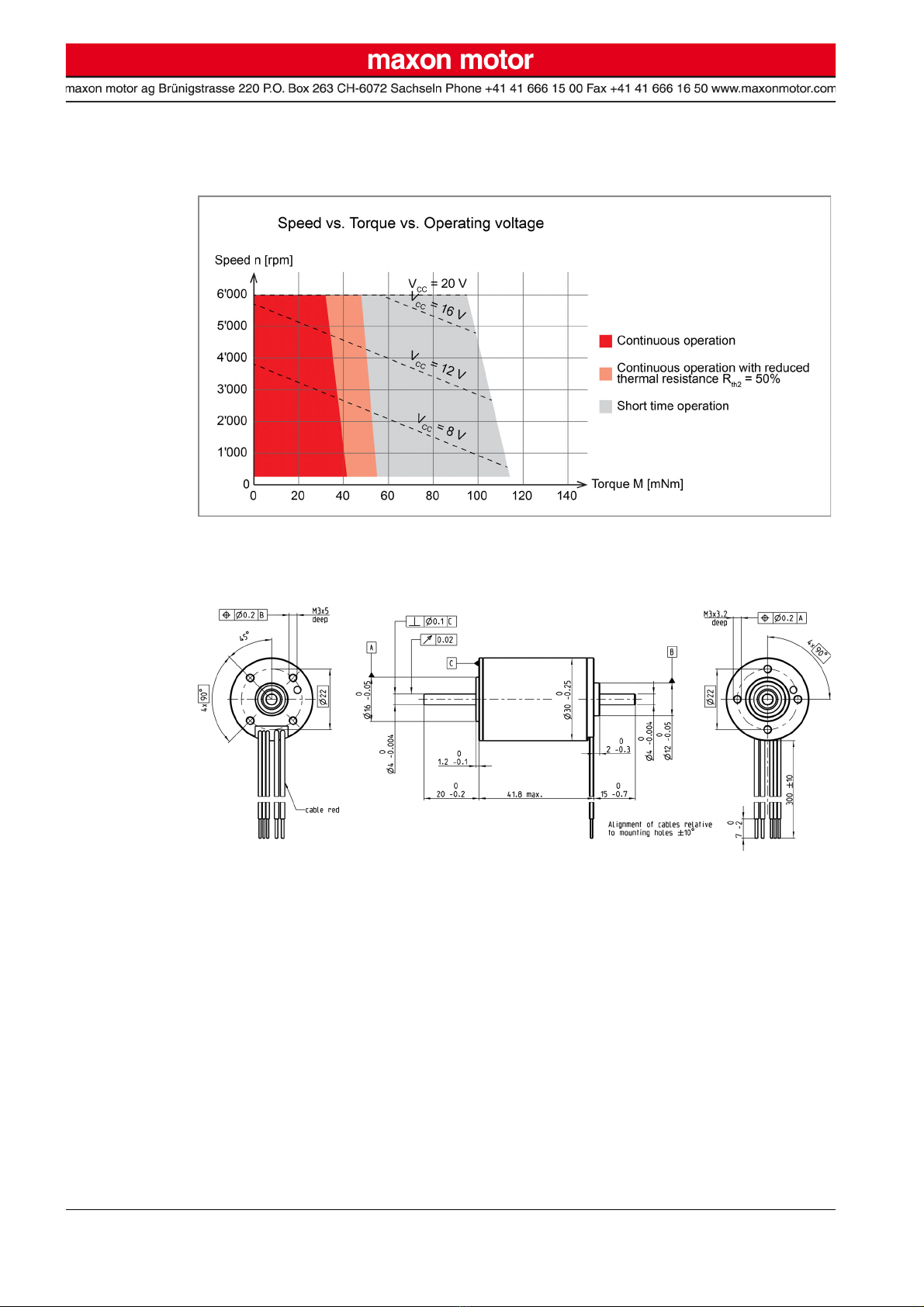

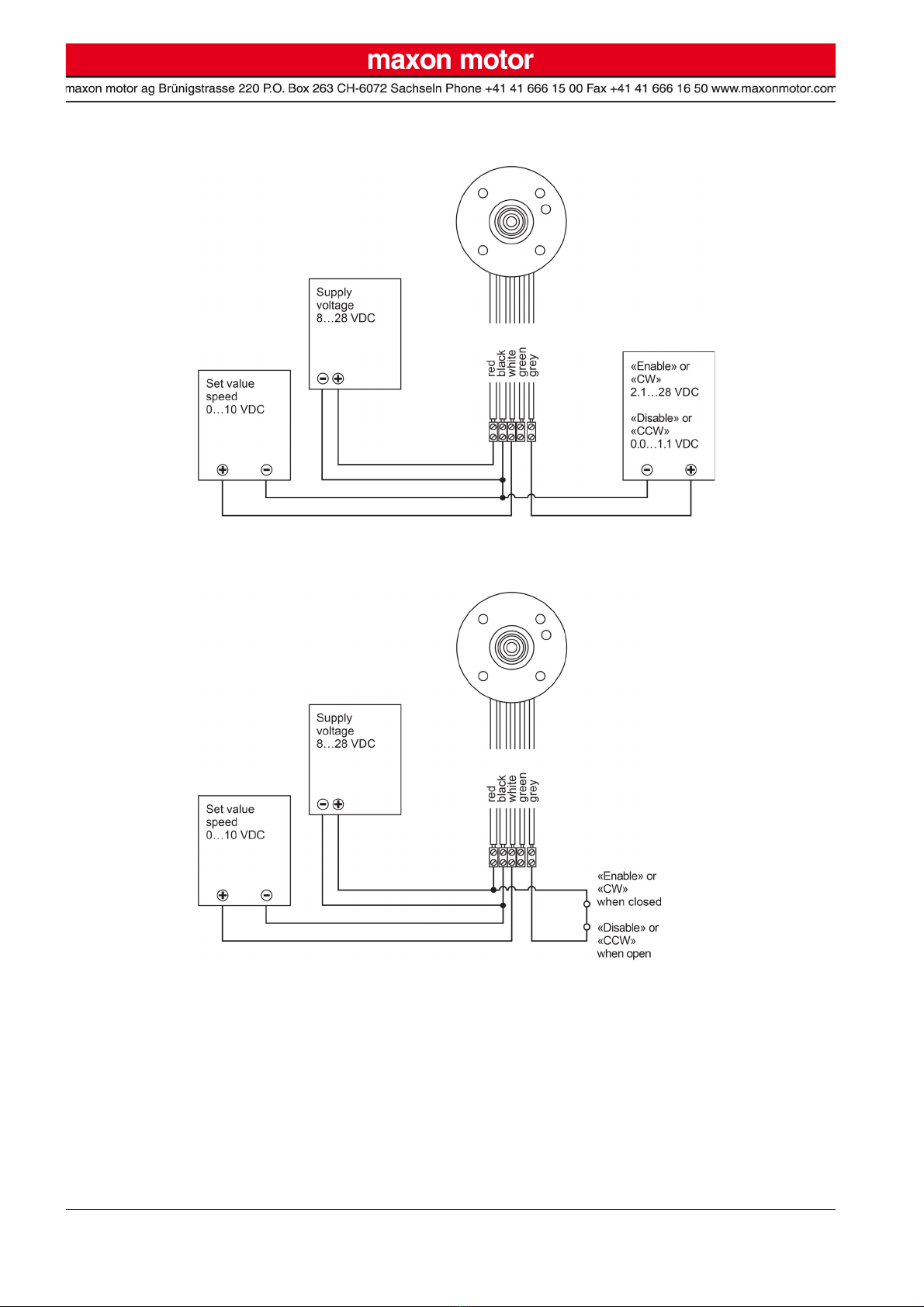

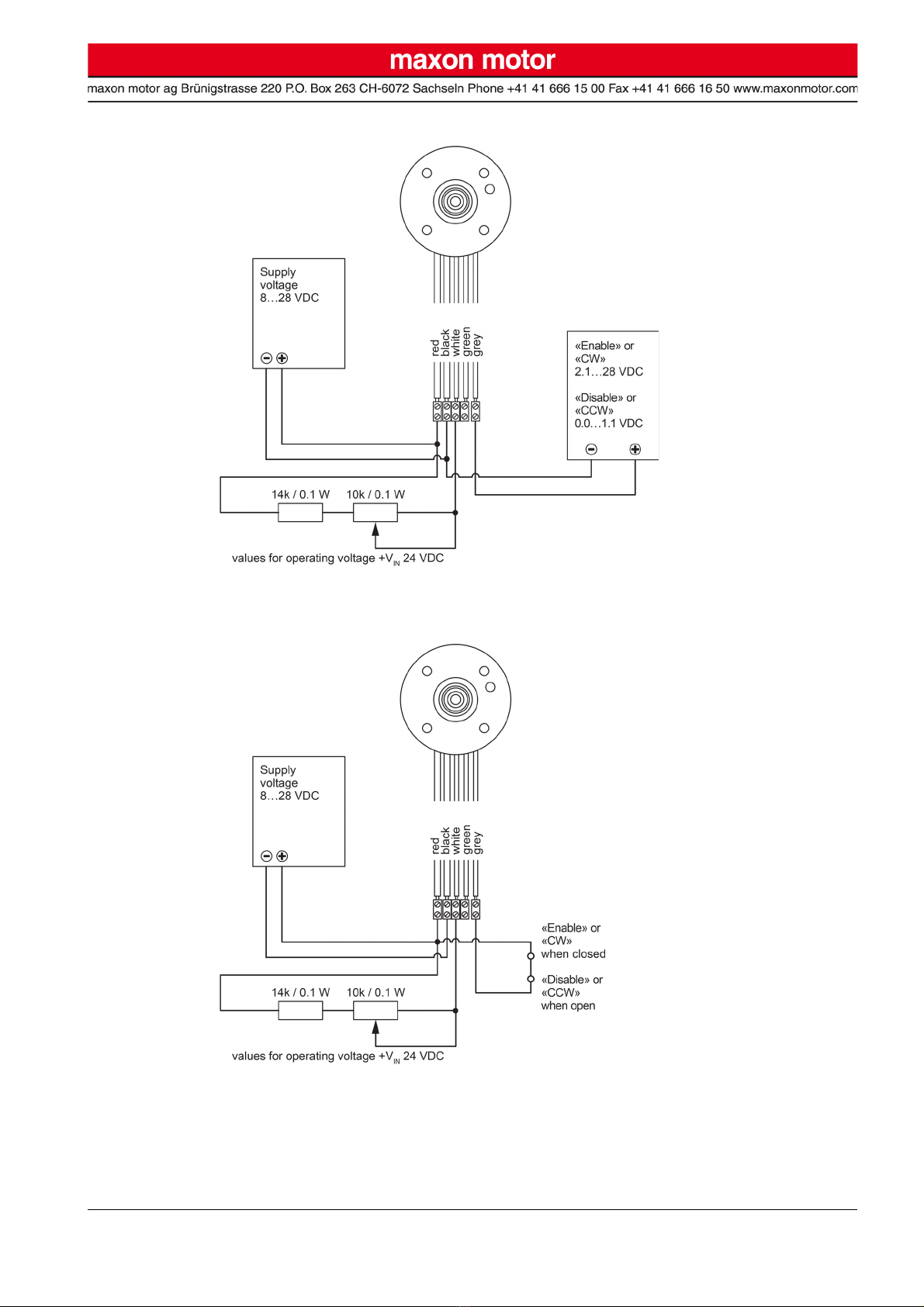

The connected supply voltage must be between 8 VDC and 28 VDC. Permanently applied voltages

above 30 VDC will destroy the unit.

Electrostatic sen-

sitive components

The built-in electronics can be destroyed by externally applied electronic discharges during transport,

installation, and during operation.

• Make sure to wear working cloth in compliance with ESD.

• Handle the device with extra care.

• Limit the voltage between flange and any live parts to 500 VDC

Temperature During operation, the temperature of housing, flange, or other components may exceed 60°C.

READ THIS FIRST

These instructions are intended for qualified technical personnel.

Prior commencing with any activities…

• you must carefully read and understand this manual and

• you must follow the instructions given therein.

The EC-i30 with integrated electronics is considered as partly completed machinery according to EU Directive 2006/42/

EC, Article 2, Clause (g) and is intended to be incorporated into or assembled with other machinery or other partly

completed machinery or equipment.

Therefore, you must not put the device into service,…

• unless you have made completely sure that the other machinery – the surrounding system the device is intended to

be incorporated to – fully complies with the requirements stated in the EU directive 2006/42/EC!

• unless the surrounding system fulfills all relevant health and safety aspects!

• unless all respective interfaces have been established and fulfill the stated requirements!