TABLE

OF

CONTENTS

DRYER

SAFETY

3

DRYER

DISPOSAL

4

INSTALLATION

REQUIREMENTS.

......2....2::-::ccecccecreseeeeeeeeeeeeeee

4

TOONS

ANd

Parts

oo.

eecccecceceneeceneeeeeaeeeeeeeeaeeseaeeseaeeseneeeeeseaeeseneeeee

4

Location

REQUIFEMENtS

.........::cccccsceccssscecssnscecesnscecssssecssnssetersens

4

6

6

7

Electrical

Requirements

-

Gas

Dryer

........ccsccccssscecesssecessenetereens

Gas

Supply

REQuireMents

.........cccscccccssssccsssscecsstssecssesecsenstersens

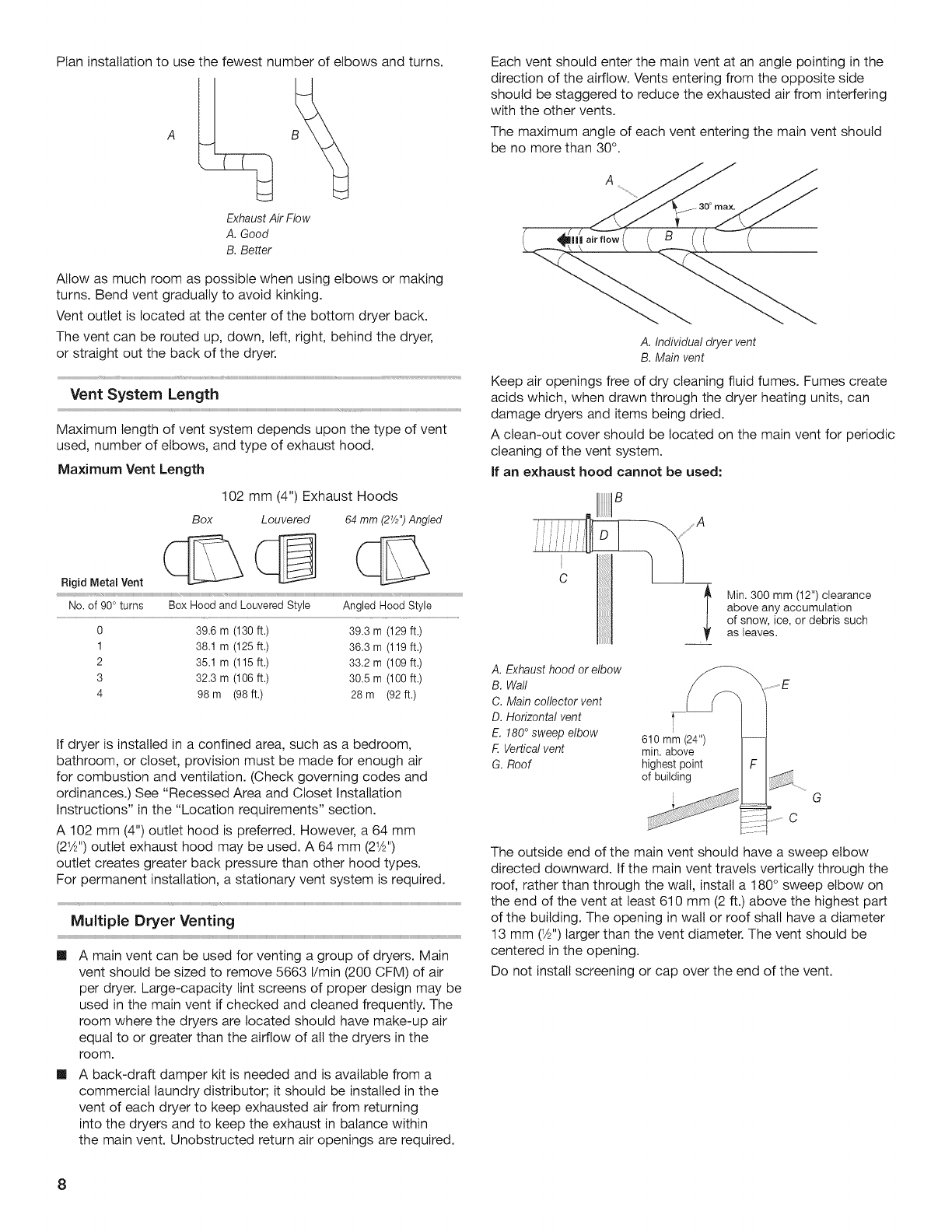

Venting

REQuirementS

.........ccscccccssccccossecccoscssecccessececessesecsessersens

INSTALLATION

INSTRUCTIONS

-

GAS

DRYER

...........:0000

9

Install

Leveling

LOGS........:.:ccccsccccsssscccssssecsssesececssesecsestecsenstersens

9

Make

Gas

Connection

.......ccccsscccosssseccssssecsenssecessaesecceesecsessersens

9

COnnect

VEN

......cccscssssccccssscecsssssecsosacecsosscecceseatecsestecsestecsoateess

9

Complete

Installation

........c.ccssceccssscecsonscecsoteceesesesaturessarursssantess

9

MAINTENANCE

INSTRUCTIONS.

..........:0ccseseeeeeeeeesseeeeerrenene

10

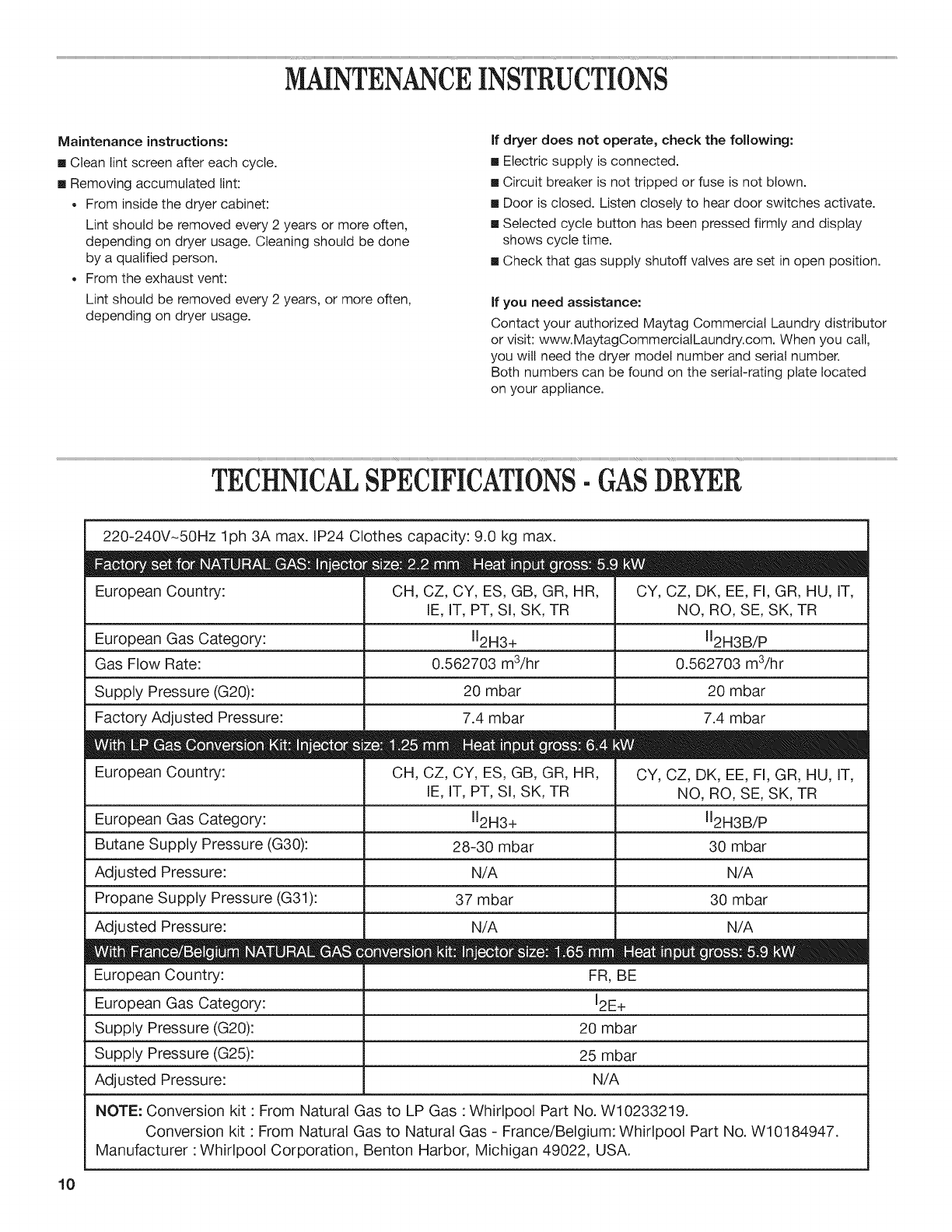

TECHNICAL

SPECIFICATIONS

~

GAS

DRYER............::0:0

10

REVERSING

THE

DOOR

SWING

(OPTIONAL).............00:00+

1

ELECTRONIC

CONTROL

SETUP?

............ss:ccessersseessresnenseeeees

13

WARRANTY

.....0::0:eccccenercesenneensensesenansesenneensneseseennsnnnnnesesnnenenanss

17

TABLE

DES

MATIERES

SECURITE

DU

SECHE-LINGE

...........22222..:::ce::eceeeeeeeeeereeeeeee

18

ELIMINATION

DU

SECHE-LINGE.

..........::cc:cecccerceeesseeenereeeecee

19

EXIGENCES

D’INSTALLATION...........2222:2:::0:ceceeeeeeeeeeeeeeseteeeees

19

Outillage

et

PISCES

.........esecccessscccessececsenscecsesscecsesscecsestecsessecsens

19

EXIQENCeS

C’EMPIlACEIMeENt

........:ccccessccecessececsssececessscecseeseceeness

20

Spécifications

électriques

-

séche-linge

&

GaZ

......cscccssseceens 21

Spécifications

de

lalimentation

EN

Gaz

.......cccssccessssecestreeeens

22

Exigences

concernant

l@VACUATION

........ccsccccesscccossscesesseecenees

23

INSTRUCTIONS

D’INSTALLATION

-

SECHE-LINGE

A

GAZ

|...

21.

.cessecccceeeececcn

eee

eneeen

ee

eeeeeeneeeneeeeeees

24

installation

des

pieds

de

nivellerMent...........cccscccccsssccessseseenees

24

Raccordement

a

la

canalisation

de

Gaz

.......ccscccsssccesstseseenees

25

Raccordement

du

conduit

c’Evacuation

.......:cccscccesseseceenees

25

Achever

Pinstallation

........cccsccccosscsccossecccossesecerseeeseseuursssesecsenses

25

INSTRUCTIONS

D’ENTRETIEN.........:c2::cccseecceeceneeeeseeeneenseeenes

25

FICHE

TECHNIQUE

-

SECHE-LINGE

A

GAZ

...............00+

26

INVERSION

DU

SENS

D’OUVERTURE

DE

LA

PORTE

.........

27

REGLAGE

DE

LA

CARTE

DE

CIRCUITS

ELECTRONIQUES.

...........22::::ccceseeeeeeeeeeeeeereeees

29

GARANTIE

..........-2ccccceceneececeeneennneceneeneenenenesesenanansensennaaeseneenennaee

33

INDICE

SEGURIDAD

DE

LA

SECADORA..

...........22.2::::::cceeeeecreeeeeeeeeeee

34

ELIMINACION

DE

LA

SECADORA.

...........sceeceeeeeeeneseens

35

REQUISITOS

DE

INSTALAGION

........:cccccesseeceeereeeneenes

35

PieZas

Y

NEPPAMENtAas

..........ccccccecececececesescensnsnsncacacecececsesesess

35

Requisitos

de

UDICACION

..........ccececccccececesescensnsnsncacacacececsesesess

35

Requisitos

eléctricos

-

S@Cadora

4

GAS

......ccsesescscscscececeesesess

37

Requisitos

del

SUMINISTO

CO

GAS......cccccsscecestssecsstssecsstssersens

37

Requisitos

de

VENtHACION

........ccccecccececesescensnsnsncacacacececsesecess

38

INSTRUCCIONES

DE

INSTALACION

-

SECADORA

A

GAS.

0...

.cessseececsneesenseetsecceseaaeeeesnaeeusenceensanenessaeas

40

Instalaci6n

de

las

patas

nivelacoras

.........c:csesescscscscececeesesess

40

Conexion

Gel

SUMINISTIO

GO

GaS............ccecececececssesessensnenenaees

40

Conexion

del

ducto

dé

ESCADE

..........ccececececececssseeesensnenenaeas

40

Complete

la

inStalacion

.....ccccccccccccccsesecusecccccecerstesesesesseeenaees

40

INSTRUCCIONES

DE

MANTENIMIENTO

............2:::cceceeeeeeee

41

ESPECIFICACIONES

TECNICAS

-

SECADORA

A

GAS

......

41

COMO

INVERTIR

EL

SENTIDO

DE

APERTURA

DE

LA

PUERTA,

.........ccecccceseseeceerseeenenennenneeeeneneeeneennnnnnesnnenneneney

42

PROGRAMAGION

DEL

CONTROL

ELECTRONIC

.............

44

GARANTIA.......cccsecesnecesnescenssessesesesecsesessesesesacsecaenessenecseneenenecess

48

INDICE

SICUREZZA

DELL’ASCIUGATRICE.

.........22....:::::::ececceeeeeeeeeeees

49

VELIMINAZIONE

DELL’ASCIUGATRICE

............:.::cs1:eereeeeesees

50

REQUISITI

D'INSTALLAZIONE.

.........22.:.-:::::::ececceseereeeeeeeeeeteeees

50

AttreZZi

©

COMPONENEL........csccccessccccessssccessececesscsecosssseceestseseeness

Requisiti

di

ubicazione

Requisiti

elettrici

-

asciugatrice

@

GAS

ee

eceeeeeeteeeteeteees

52

Requisiti

di

alimentazione

Gel

QaS..........ccssscccstssecessssecsstssecsens

52

REQUISIEL

Ci

SCALICO

oo.

ccccecccececccccecececeseeceensnsncacacscececsesesess

53

ISTRUZIONI

DI

INSTALLAZIONE

-

ASCIUGATRICE

DB

GAS.

0c

ceceecescn

eevee

ee

encaneenenne

ee

suanenenanennenaesecaaeesesaaeeseeasensaaaenseaaass

55

installazione

dei

piedini

di

regolaZione’

..........ccsscccesssecsetsseceens

55

Eseguire

il

Colleganento

QaS

........:cccssssccsssssecsstssecsenssecsetssersens

55

Gonnessione

dello

SCAriCO

oo.

cecccetceeeeeceeeceteeseeeeeneeeteeesteeteaes

55

Completamento

dell’installaZione

.........::ccccssersctssecsessecsotareess

56

ISTRUZIONI

DI

MANUTENZIONE.

............:::cseeeensseeeseeenereeeenee

57

DATI

TECNICI

-

ASCIUGATRICE

A

GAS.

..........2::::eeeeeeee

57

INVERSIONE

DELLA

ROTAZIONE

DI

APERTURA

...............

58

CONFIGURAZIONE

DEI

CONTROLLI

ELETTRONIC!

..........

60

GARANZIA

.....ccesccsccssccssceecesneessenaeesneneesaeesnenaeeeaeeaneneteaetasenaeersase

64