10

Your dryer can be installed in a basement, laundry room, or

recessed area.

Companion appliance locaon requirements should also be

considered.

Do not install or store the dryer where it

will be exposed to the weather. Proper installaon is your

responsibility.

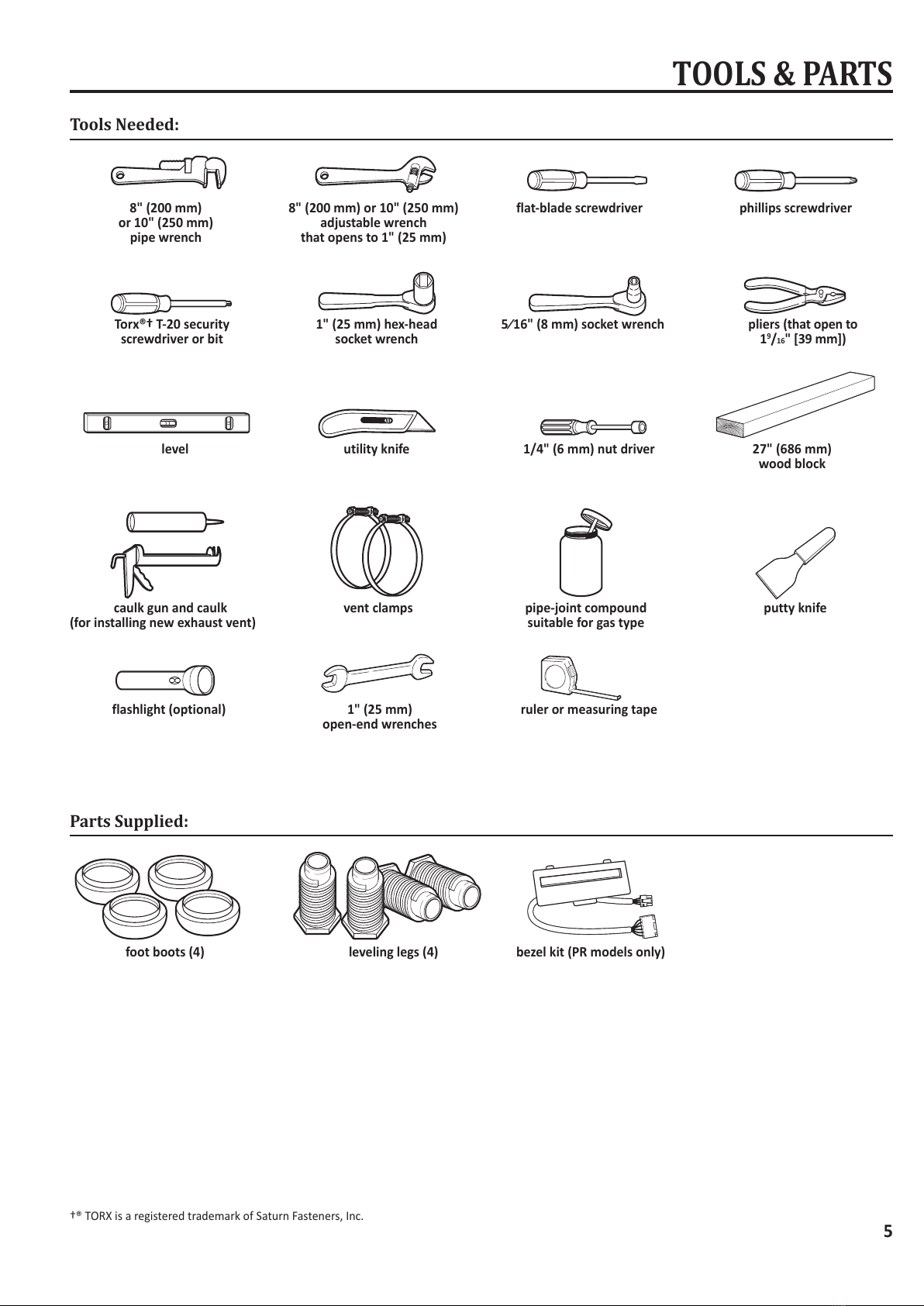

You will need:

■A grounded electrical outlet located within 6 . (1.8 m) of

where the power cord is aached to the back of the dryer.

See “Electrical Requirements.”

■A level oor with a maximum slope of 1" (25 mm) under

enre dryer. Installing the dryer on so oor surfaces,

such as carpets or surfaces with foam backing, is not

recommended.

Electric dryer installation clearances

■The locaon must be large enough to allow the dryer door

to be fully opened.

■Addional spacing should be considered for ease of

installaon and servicing. The door opens more than 180°.

■Addional clearances might be required for wall, door, and

oor moldings.

■Addional spacing of 1" (25 mm) on all sides of the dryer is

recommended to reduce noise transfer.

This dryer may be installed in a recessed area or closet. For

recessed area and closet installaons, minimum clearances

can be found on the warning label on the rear of the dryer

or in “Dimensions/Clearances.”

The installaon spacing is in inches and is the minimum

allowable. Addional spacing should be considered for ease

of installaon, servicing, and compliance with local codes and

ordinances.

If closet door is installed, the minimum unobstructed air

opening in the top and boom is required. Louvered doors

with equivalent air openings are acceptable.

The dryer must be exhausted outdoors.

24 in.2

(155 cm2)

48 in.2

(310 cm2)3"

(76 mm)

3"

(76 mm)

Closet

door

Front

View

ELECTRIC DRYER INSTALLATION REQUIREMENTS

closet

door

front

view

■To contact a qualied electrical installer.

■ To be sure that the electrical connecon is adequate and in

conformance with the Naonal Electrical Code, ANSI/NFPA

70-latest edion and all local codes and ordinances.

■ The Naonal Electrical Code requires a 4-wire power

supply connecon for homes built aer 1996, dryer circuits

involved in remodeling aer 1996, and all mobile home

installaons.

■ A copy of the above code standards can be obtained from:

Naonal Fire Protecon Associaon, One Baerymarch

Park, Quincy, MA 02269.

■ To supply the required 3 or 4 wire, single phase, 120/240

volt, 60 Hz., AC only electrical supply (or 3 or 4 wire,

120/208 volt electrical supply, if specied on the serial/

rang plate) on a separate 30-amp circuit, fused on both

sides of the line. A me delay fuse or circuit breaker is

recommended. Connect to an individual branch circuit.

Do not have a fuse in the neutral or grounding circuit.

■Do not use an extension cord.

■ If codes permit and a separate ground wire is used, it is

recommended that a qualied electrician determine that

the ground path is adequate.