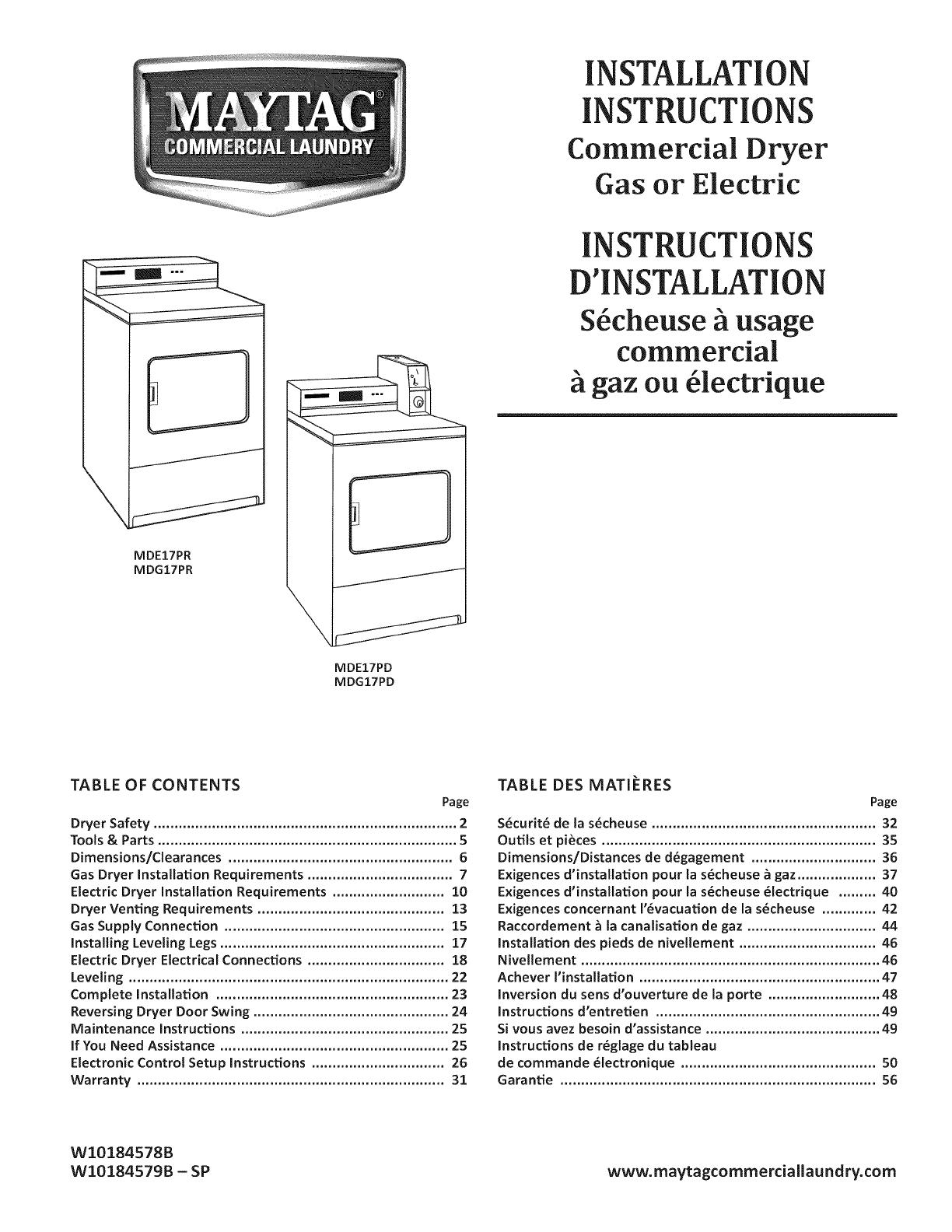

PWG

VLE

COMMERCIAL

LAUNDRY

MDE1L7PR

MDG17PR

MDE17PD

MDG17PD

TABLE

OF

CONTENTS

Page

Dryer

Safety

.....ccccccscccsccccccseeeeseeeeseeeeeeeseeeseceesscesseeeseeeeseeeeeees

2

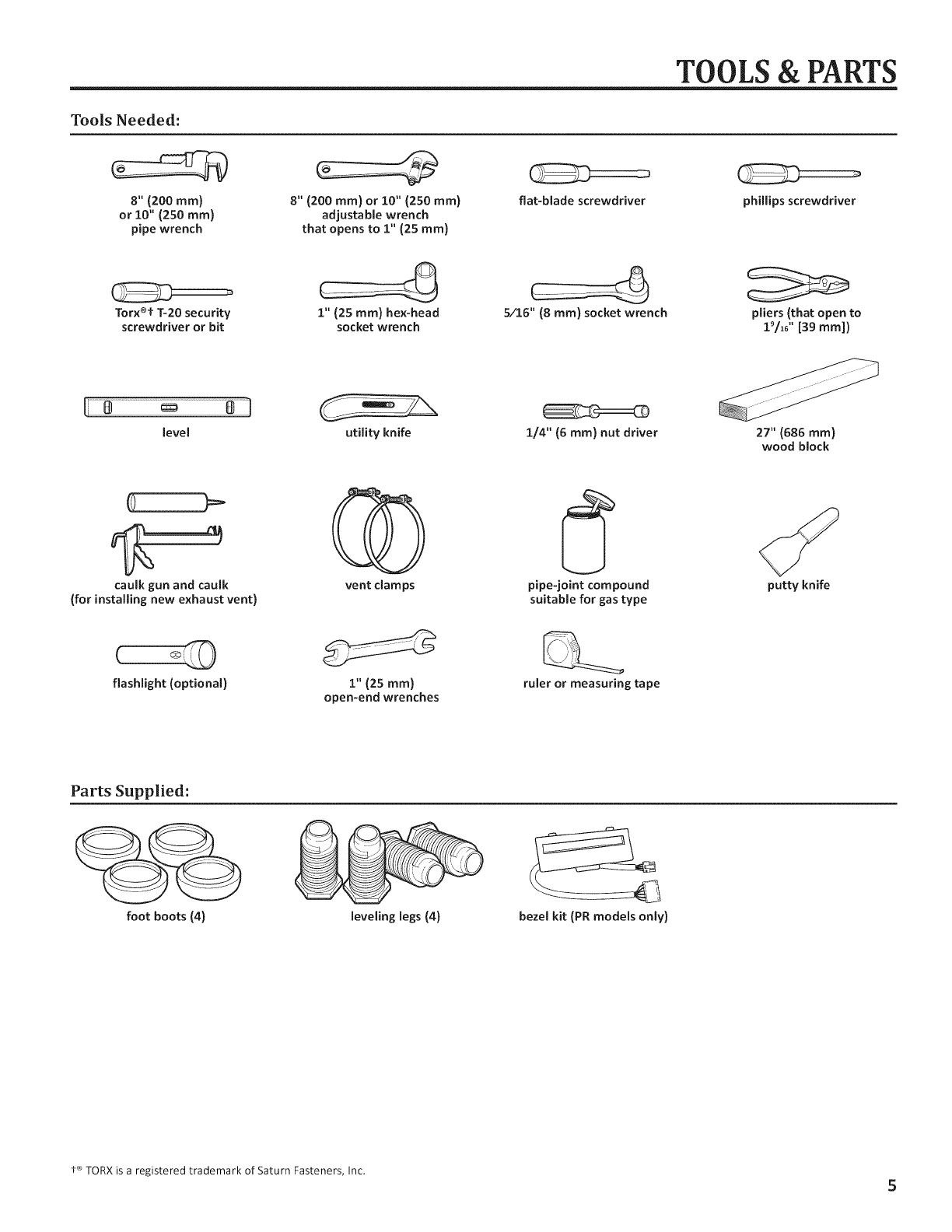

TOOIS

&

Parts

...ccsccsesscsseceeeeeeeeeessssssesassseeedeeeeeeeeeeeeeeeesesseeeaaaaes

5

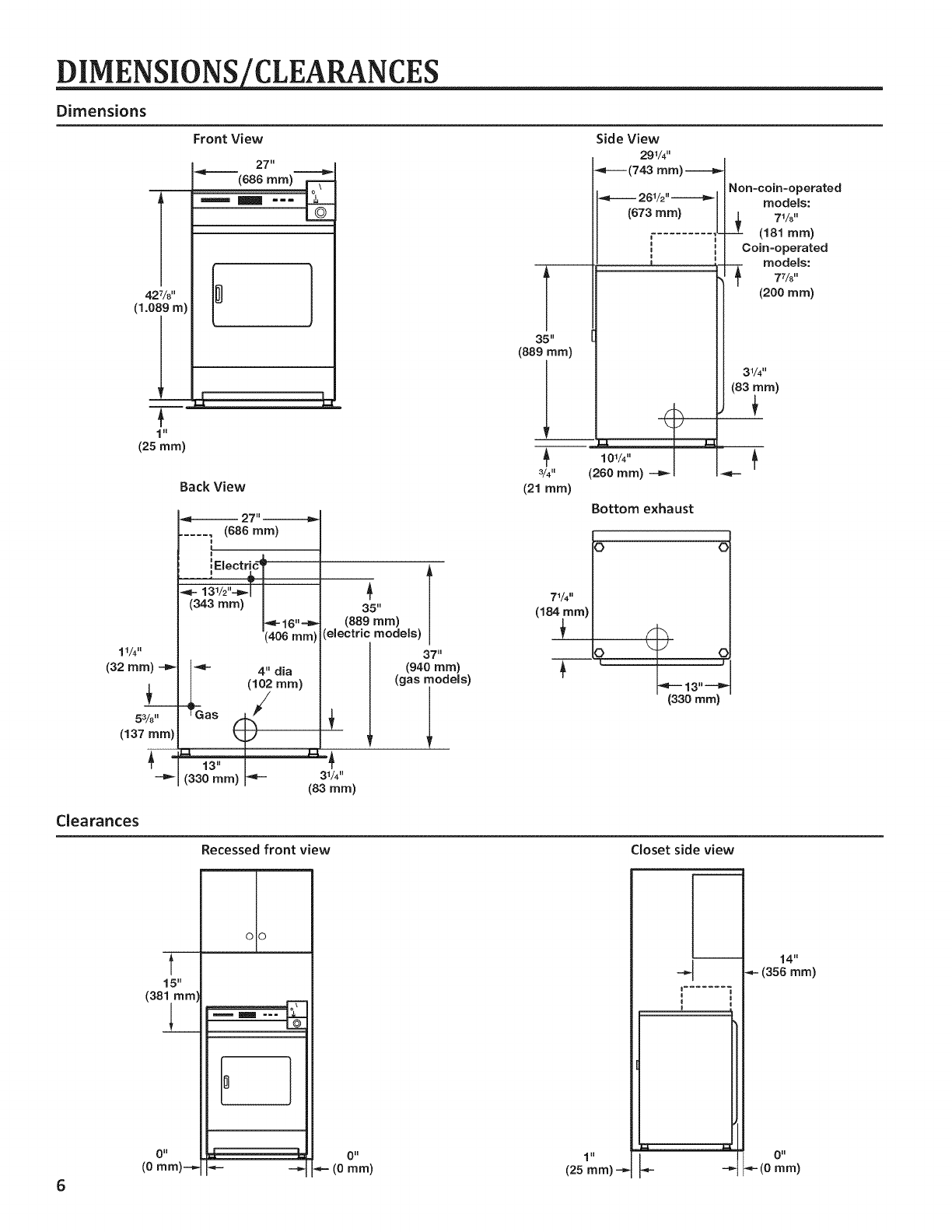

Dirmensions/CI@ArANCes

.occccccccccccceceessssessseeccanseceeteceensesteess

6

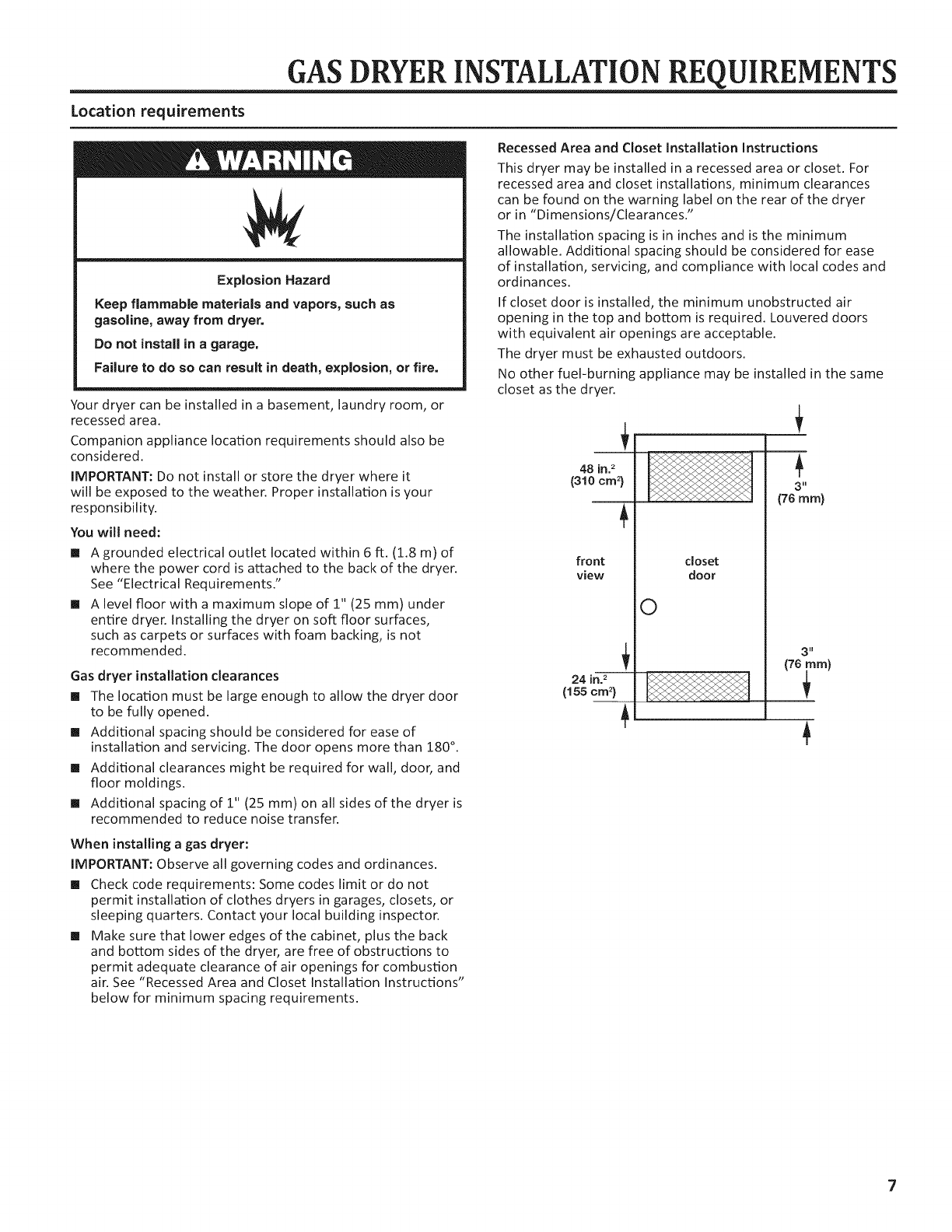

Gas

Dryer

Installation

Requirements

.......cccccccssssssssssseeseeeeees

7

Electric

Dryer

Installation

Requirements

....cccccccccecsseeeeeees

10

Dryer

Venting

Requirement

........:ccccceeseceeeeeeeeeseeeeeeeeeesseees

13

Gas

Supply

CONNECTION

00.

ccccccccccsseeeeeeeeeseeeseeeseeeeeeeeeeeeeeeees

15

Installing

Leveling

LegS

......:::ccsssssseeeeeeeeeeceeeeeeeeeeeseeeeseeeseeees

17

Electric

Dryer

Electrical

COMMECTIONS

.....ccccccccesssseseeeseeeeeeees

18

LOVGHIIG

....ccccccccssscceccccasseccncccaaucccnaeceenecceaassenseecauseeesaseauasces

22

Complete

INStalation

.....cccccssssssessseeeeeeeeeseseeseeeeeeneeeeseeeseeees

23

Reversing

Dryer

Door

SWING

......c:ccccccceseeceeeeeeesseeeeeeeeeeseseees

24

Maintenance

Instructions

.......cccccsccceeeeeeeeeeeeeeeeeeeeeeeseseeeeees

25

If

You

Need

ASSISTANCE

.....ccccccsessseeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeneeeeees

25

Electronic

Control

Setup

INStructions

.....cccccccccsssssseeseeeeeeees

26

Warranty

..ccccocsecccsssccsssesonsesonsnscnsaseessescasescasaseasaseesausesanauss

31

W10184578B

W10184579B

—

SP

INSTALLATION

INSTRUCTIONS

Commercial

Dryer

Gas

or

Electric

INSTRUCTIONS

D'

INSTALLATION

Sécheuse

a

usage

commercial

a

gaz

ou

électrique

TABLE

DES

MATIERES

Page

SEcurité

de

la

sECHGUSE

......cccccececessssesssnnnancacceeseeesseetseessaaes

32

Outils

Ct

PI@COS

...ececcccsssseensseseseeeeeeeeeeseseeeeeannssseeeeeeeeeeeeeeeees

35

Dimensions/Distances

de

dégagement

........:.:csessseeceseeeeeee

36

Exigences

d’installation

pour

la

sécheuse

@

BaZ.....cccsccseeeeees

37

Exigences

d’installation

pour

la

sécheuse

électrique

.........

40

Exigences

concernant

l’évacuation

de

la

sécheuse

......000:

42

Raccordement

a

la

canalisation

de

Baz

......ccssssssssnssscnseeesees

44

Installation

des

pieds

de

nivelleMment

........ccssssssssssssecsseeesees

46

Nivell@ment

.......ccccccccceeeeeeseeeeeeessessseeeeeeeeeesssseseeseeaaeeeeeeeeeeees

46

Achever

Vinstallation

.........ccccssccsssscssssnsscensseeseeesseesseessssnanaes

47

Inversion

du

sens

d’ouverture

de

la

POrte

......ccsssssssssseeseseees

48

INStFUCTIONS

C’ANTPETION

0.0...

ccsccssscccsccessesssesssssnsssnnsecanaseeesees

49

Si

vous

avez

besoin

d’assistance

.......csssssccsscesseessessssessssenaes

49

Instructions

de

réglage

du

tableau

de

commande

Electronique

......ccsssssssssccsccesssssseessssssssseaases

50

CE)

ga

| 6 |

ee

56

www.maytagcommerciallaundry.com