Mazda 121 Instruction manual

Other Mazda Automobile manuals

Mazda

Mazda 2007 Mazdaspeed 3 Guide

Mazda

Mazda 1990 MX-5 Instruction manual

Mazda

Mazda 2004 6 Assembly instructions

Mazda

Mazda 2 User manual

Mazda

Mazda Mazda 6 Reference manual

Mazda

Mazda 2008 Tribute User manual

Mazda

Mazda Mazda 6 Instruction manual

Mazda

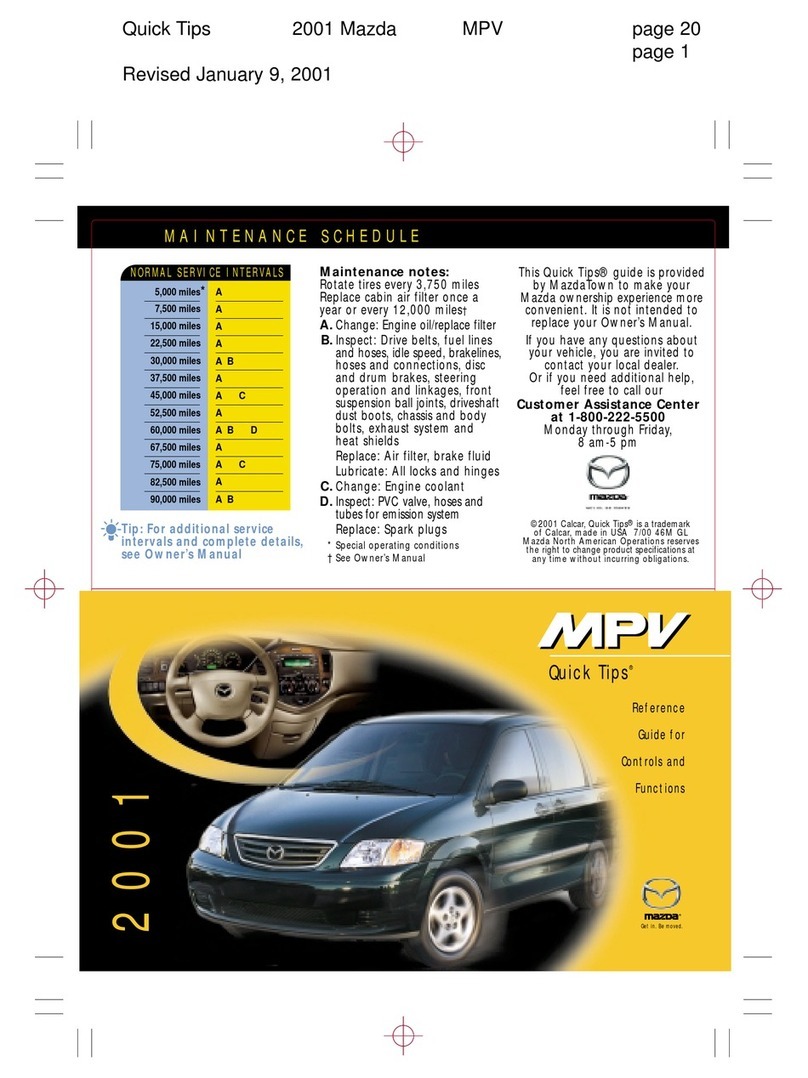

Mazda 2006 MPV User manual

Mazda

Mazda Automobile User manual

Mazda

Mazda 1979-1984 RX7 Reference manual

Mazda

Mazda CX-3 Guide

Mazda

Mazda car Instruction manual

Mazda

Mazda 2008 Mazda5 User manual

Mazda

Mazda 6 2002 Instruction manual

Mazda

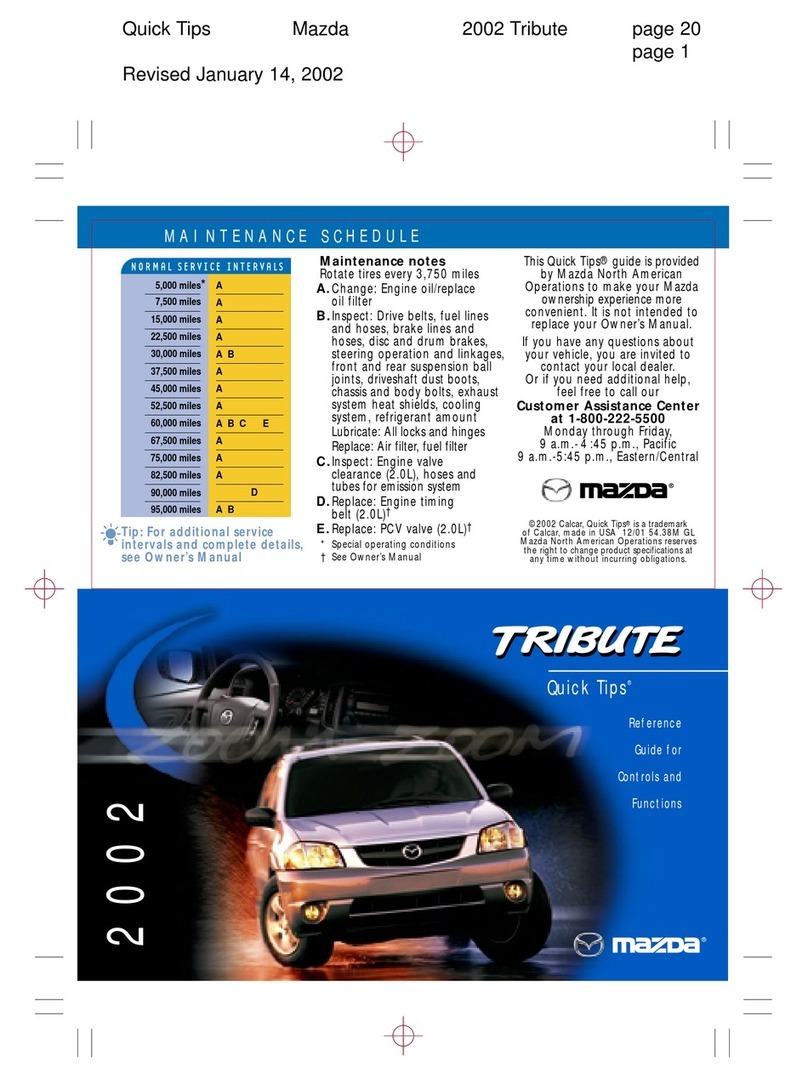

Mazda 2002 Tribute Assembly instructions

Mazda

Mazda 2009 5 User manual

Mazda

Mazda 2010 Tribute Guide

Mazda

Mazda 2012 CX5 User manual

Mazda

Mazda 2007 Mazdaspeed 3 User manual

Mazda

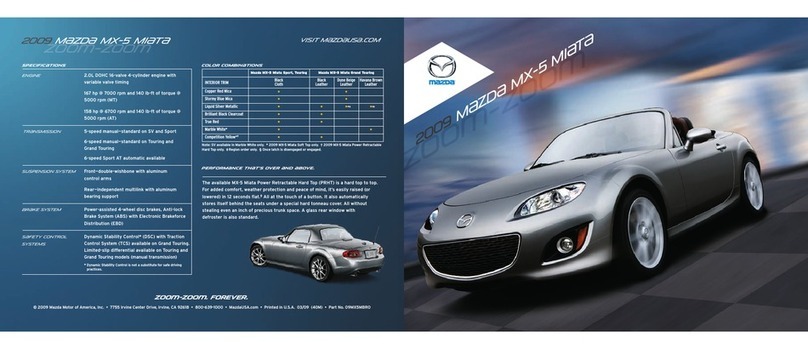

Mazda 2009 MX-5 Miata User manual