FUSIBLE LINK REFERENCE CHART NO. T-2-3

Article Text

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

Monday, August 27, 2001 06:31AM

ARTICLE BEGINNING

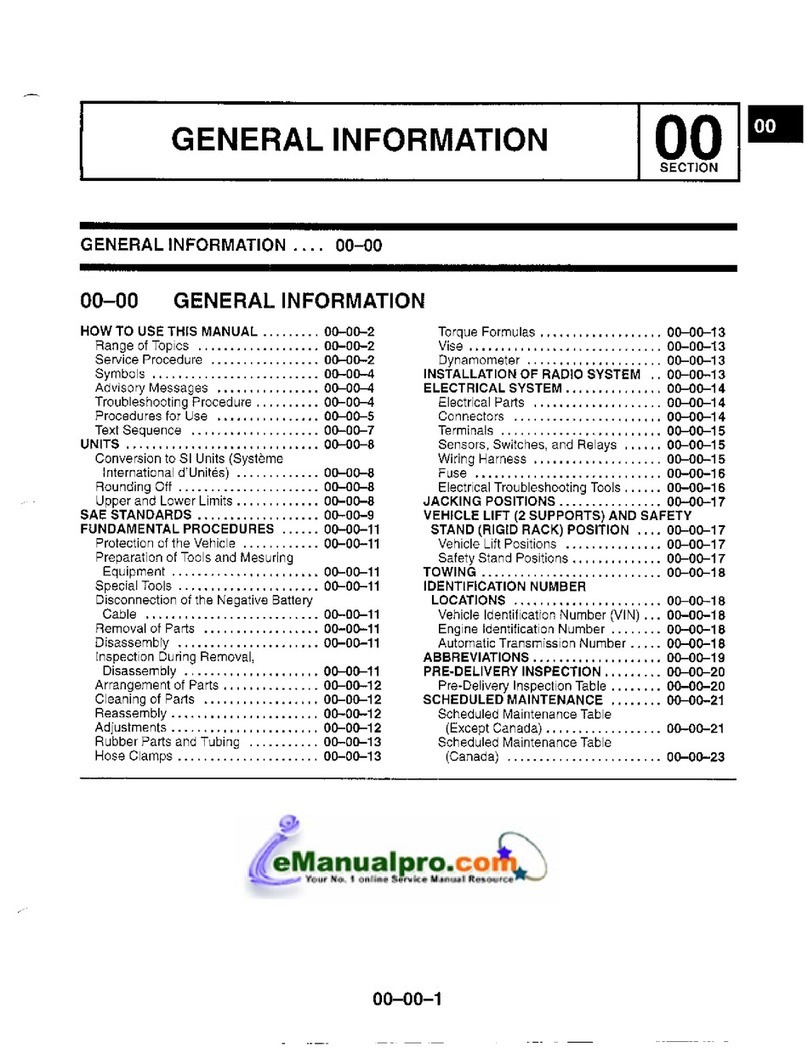

TECHNICAL SERVICE BULLETIN

FUSIBLE LINK REFERENCE CHART

Model: All Mazda

Date: November 1, 1990 (Revised - April 27, 1992)

No: T-2-3

Group: Parts Bulletin

SERVICE INFORMATION

For easy reference, the following list of Fusible Links have been

compiled.

FUSIBLE LINK REFERENCE CHART

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ

Year Model Location P/N

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ

1979-82 626 Engine Compartment 8174-66-760B

1983-85 626 Gas Engine Compartment 3775-67-099

1983-85 626 Diesel Engine Compartment H047-67-099

1983-85 626 Alternator HA67-67-099

1979 RX-7 Under Dash 1175-66-710A

1980 RX-7 Under Dash 8130-66-710

1980 RX-7 Engine Compartment 8341-18-055

1981 RX-7 Under Dash FA02-67-099

1981-85 RX-7 Engine Compartment 3777-67-099

1981-85 RX-7 Transmission 8341-18-055

1981-85 RX-7 Engine Compartment 8871-67-099

1984-85 RX-7 Engine Compartment 3775-67-099

1981-85 GLC Engine Compartment B003-67-099

1981-85 GLC Engine Compartment B005-67-099

1981-85 GLC Engine Compartment B006-67-099

1977-82 B2000 Engine Compartment B094-67-099

1983-84 B2000/B2200 Engine Compartment UA47-66-099

1988-93 MX-6 Engine Compartment FB01-67-099

M/T,

Non-Turbo A/T

1988-93 626 Sedan Engine Compartment FB01-67-099

1988-93 626 Hatchback Engine Compartment FB01-67-099

M/T,

Non-Turbo A/T

1990-92 929, 929S Engine Compartment FB01-67-099

1986-92 323 Engine Compartment FB01-67-099

1987-89 323 Wagon Engine Compartment FB01-67-099

1986-91, 93 RX-7 Engine Compartment FB01-67-099