00

GENERAL INFORMATION

00–00–1

SECTION

00–00

To c o f S C T

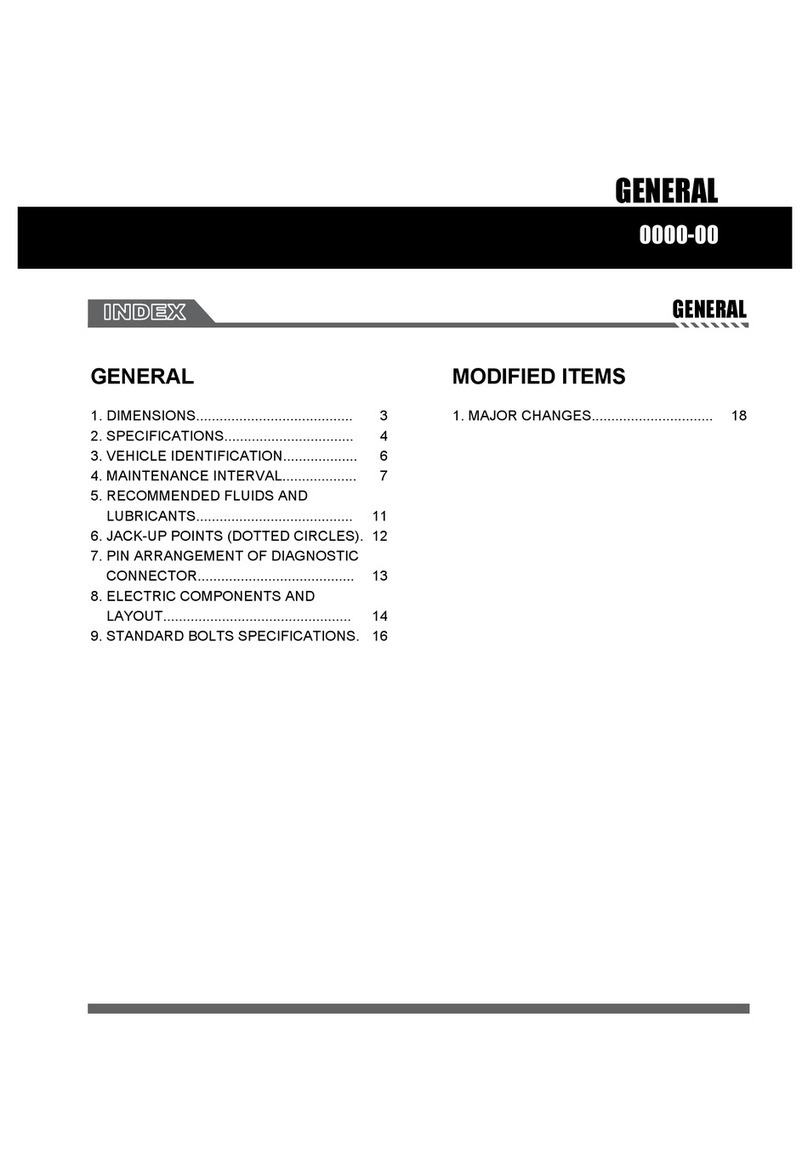

GENERAL INFORMATION . . . . 00-00

To c o f S C T

00–00 GENERAL INFORMATION

HOW TO USE THIS MANUAL . . . . . . . . . 00–00–2

Range of Topics . . . . . . . . . . . . . . . . . . 00–00–2

Service Procedure . . . . . . . . . . . . . . . . 00–00–2

Symbols . . . . . . . . . . . . . . . . . . . . . . . . 00–00–4

Advisory Messages. . . . . . . . . . . . . . . . 00–00–4

UNITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00–00–5

Conversion to SI Units (Système

International d'Unités) . . . . . . . . . . . . . 00–00–5

Rounding Off . . . . . . . . . . . . . . . . . . . . . 00–00–5

Upper and Lower Limits . . . . . . . . . . . . 00–00–5

FUNDAMENTAL PROCEDURES. . . . . . . 00–00–6

Preparation of Tools and Measuring

Equipment. . . . . . . . . . . . . . . . . . . . . . 00–00–6

Special Service Tools . . . . . . . . . . . . . . 00–00–6

Disassembly . . . . . . . . . . . . . . . . . . . . . 00–00–6

Inspection During Removal,

Disassembly . . . . . . . . . . . . . . . . . . . . 00–00–6

Arrangement of Parts . . . . . . . . . . . . . . 00–00–7

Cleaning of Parts . . . . . . . . . . . . . . . . . 00–00–7

Reassembly . . . . . . . . . . . . . . . . . . . . . 00–00–7

Adjustment . . . . . . . . . . . . . . . . . . . . . . 00–00–7

Rubber Parts and Tubing . . . . . . . . . . . 00–00–8

Hose Clamps . . . . . . . . . . . . . . . . . . . . 00–00–8

Torque Formulas . . . . . . . . . . . . . . . . . 00–00–8

Vise . . . . . . . . . . . . . . . . . . . . . . . . . . . 00–00–8

ELECTRICAL SYSTEM. . . . . . . . . . . . . . 00–00–9

Connectors. . . . . . . . . . . . . . . . . . . . . . 00–00–9

NEW STANDARDS . . . . . . . . . . . . . . . . . 00–00–11

ABBREVIATIONS . . . . . . . . . . . . . . . . . . 00–00–12

End of Toc