00

GENERAL INFORMATION

00-00–1

SECTION

00-00

Toc of SCT

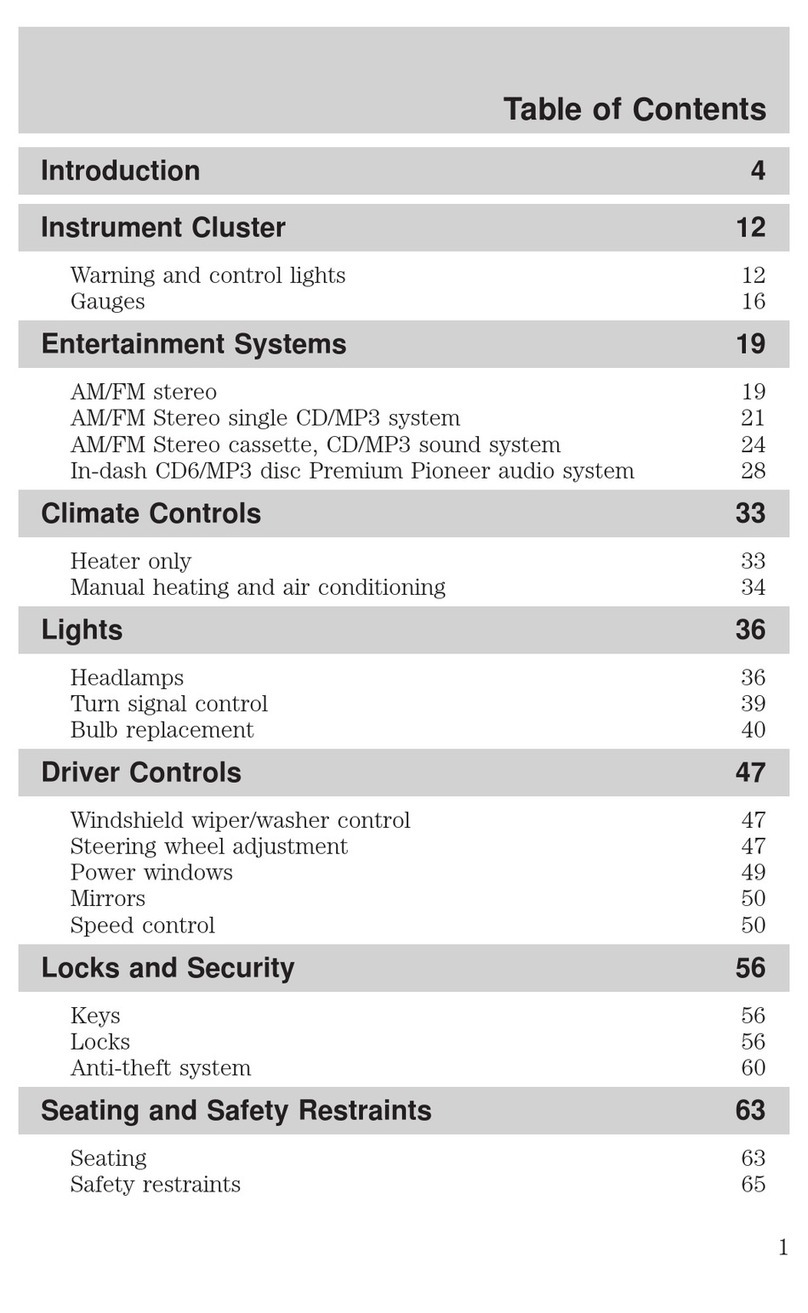

GENERAL INFORMATION . . . .00-00

Toc of SCT

00-00 GENERAL INFORMATION

VEHICLE IDENTIFICATION NUMBER

(VIN) CODE . . . . . . . . . . . . . . . . . . . . . .00-00–2

2009 MY . . . . . . . . . . . . . . . . . . . . . . . . 00-00–2

2010 MY . . . . . . . . . . . . . . . . . . . . . . . . 00-00–3

VEHICLE IDENTIFICATION NUMBERS

(VIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . .00-00–3

2009 MY . . . . . . . . . . . . . . . . . . . . . . . . 00-00–3

2010 MY . . . . . . . . . . . . . . . . . . . . . . . . 00-00–3

HOW TO USE THIS MANUAL . . . . . . . . .00-00–4

Efficient Replacement of

Body Panels . . . . . . . . . . . . . . . . . . . .00-00–4

Symbols of Panel Replacement . . . . . .00-00–4

Body Dimensions

(Flat-plane Dimensions) . . . . . . . . . . .00-00–5

Body Dimensions

(Straight-line Dimensions) . . . . . . . . .00-00–6

Symbols of Body Dimensions. . . . . . . .00-00–9

AIR BAG SYSTEM

SERVICE WARNINGS . . . . . . . . . . . . . .00-00–9

Air Bag Module Inspection . . . . . . . . . .00-00–9

Air Bag Module Handling . . . . . . . . . . .00-00–9

Side Air Bag Module Handling . . . . . . .00-00–10

SAS Control Module Handling . . . . . . .00-00–10

Side Air Bag Sensor Handling. . . . . . . .00-00–10

Pre-tensioner Seat Belt Inspection . . . .00-00–10

SERVICE PRECAUTIONS . . . . . . . . . . . .00-00–11

Arrangement of Workshop . . . . . . . . . .00-00–11

Safety Precautions . . . . . . . . . . . . . . . .00-00–11

Vehicle Protection . . . . . . . . . . . . . . . . .00-00–11

Remove Dangerous Articles . . . . . . . . .00-00–11

Use of Pulling Equipment . . . . . . . . . . .00-00–12

Prevent Short Circuits. . . . . . . . . . . . . .00-00–12

EFFICIENT REMOVAL OF

BODY PANELS . . . . . . . . . . . . . . . . . . . 00-00–12

Body Measurements . . . . . . . . . . . . . . 00-00–12

Prevention of Body Deformation. . . . . . 00-00–13

Selection of Cut-and-join Locations . . . 00-00–13

Removal of Associated Parts . . . . . . . . 00-00–13

Rough Cutting of Damaged Panel . . . . 00-00–13

EFFICIENT INSTALLATION OF

BODY PANELS . . . . . . . . . . . . . . . . . . . 00-00–13

Checking Preweld Measurements And

Watching . . . . . . . . . . . . . . . . . . . . . . 00-00–13

Welding Notes . . . . . . . . . . . . . . . . . . . 00-00–14

Spot Welding Notes . . . . . . . . . . . . . . . 00-00–14

Checking Weld Strength. . . . . . . . . . . . 00-00–15

INSTALLATION PREPARATIONS. . . . . . 00-00–16

Rough Cutting of New Parts. . . . . . . . . 00-00–16

Determination of Welding Method . . . . 00-00–16

Making Holes for CO2Arc Welding . . . 00-00–16

Application of Weld-through Primer . . . 00-00–17

ANTICORROSION, SOUND INSULATION,

AND VIBRATION INSULATION . . . . . . 00-00–17

Body Sealing . . . . . . . . . . . . . . . . . . . . 00-00–17

Application of Undercoating . . . . . . . . . 00-00–17

Application of Rust Inhibitor . . . . . . . . . 00-00–18

Application of Floor Silencer. . . . . . . . . 00-00–18

BODY COLORS. . . . . . . . . . . . . . . . . . . . 00-00–18

Color Code and Color Name . . . . . . . . 00-00–18

Verification of Primary Color Mixture for

Body Color . . . . . . . . . . . . . . . . . . . . . 00-00–18

ABBREVIATION . . . . . . . . . . . . . . . . . . . 00-00–18

IDENTIFICATION NUMBER

LOCATIONS . . . . . . . . . . . . . . . . . . . . . 00-00–19

Vehicle Identification Number (VIN) . . . 00-00–19

Engine Identification Number. . . . . . . . 00-00–19

End of Toc

BM: GENERAL INFORMATION

3442-1U-09G.book 1 ページ 2009年7月22日 水曜日 午前11時7分