Installation and Operating Instructions for WG 36/09.12/

Rod-Type Level Probe NT Original operating manual E-MBA 322b

The rod-type level probe NT measures the temperature of the liquid

with a Pt 100 temperature sensor (DIN EN 60751) and the level of

the liquid by means of conductive level measurements.

The level probes NT are only designed for commercial and

industrial use.

Do not use them in inflammable or explosive fluids.

In order to ensure correct and reliable operation, the following must

be observed:

1. Electrical Safety

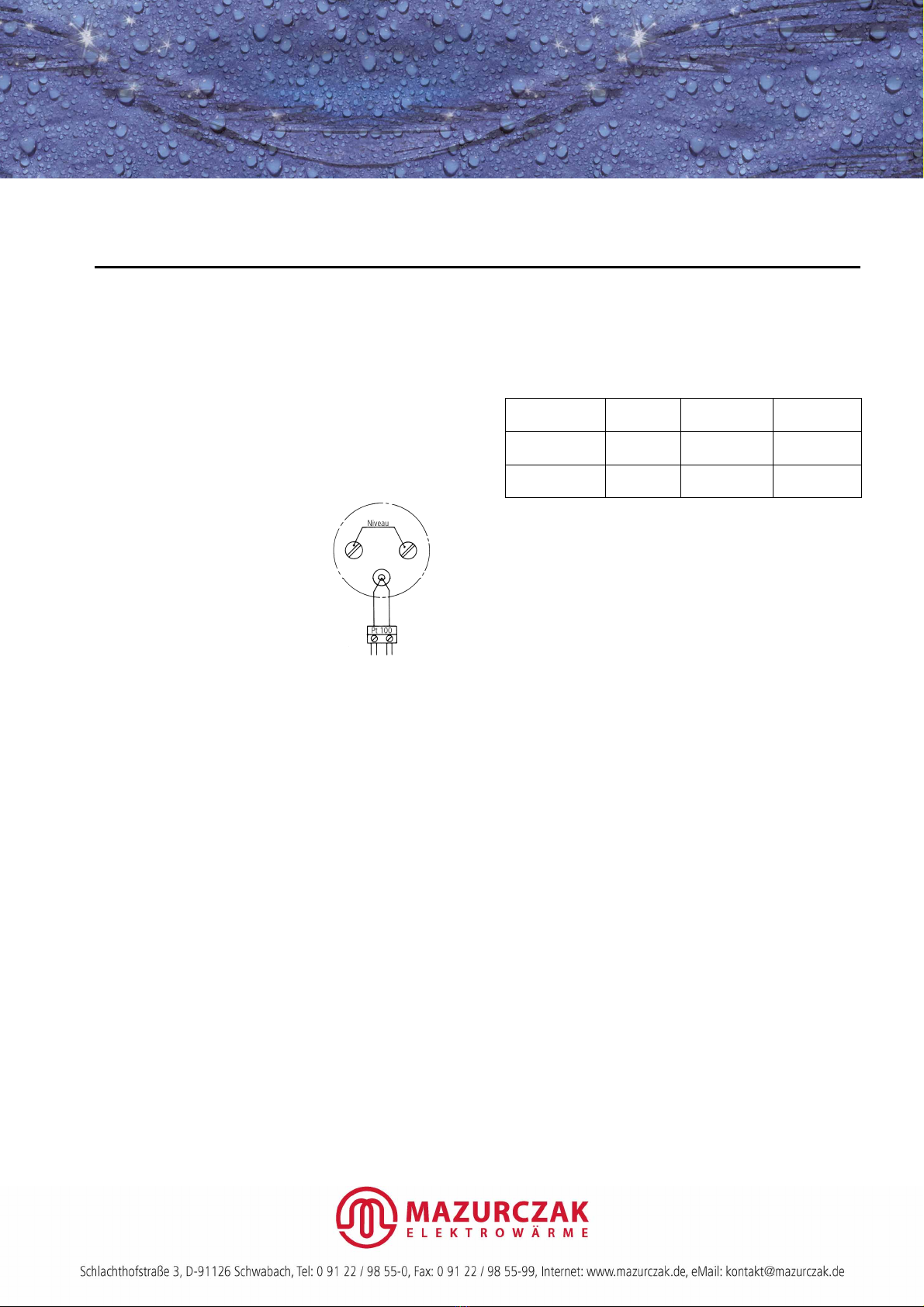

Connection diagram

The probe may be connected only

by a suitably trained electrician!

The probes may be used only together

with a suitable electronic controller.

Maximum probe voltage: 20 V ~ (AC).

In the case of inductively or capacitively

coupled interference on the control

cable, we recommend that you use

screened cables. The screen may be

connected to ground only at one end of

the cable.

Types NT…/BC-…

The terminal casing BC is opened and closed with the mounting

wrench SB. For terminal casing BC, ensure that the pull relief, the

pressure screw for the cable gland and the cover screws are correctly

tightened upon assembly. Tighten the terminal casing cover until the

cover makes a positive connection with the cable gland. This ensures

optimum sealing of the casing.

Types NT…/LC-…

The mounting wrench SL (accessory) is used for opening and closing

the terminal casing LC. Take care that the pull-relief, the pressure

screw and the cover are tightened securely. Tighten the terminal

casing cover until the cover makes a positive connection with the

cable gland. This ensures optimum sealing of the casing.

If you install your own cables, you must remove the white plastic

insert below the pull-relief clamp when installing cables with a

diameter of >8 mm (maximum cable diameter: 9.5 mm).

The sealing insert for the cable gland must be selected from the

following table. If replacement inserts are needed, they can be

ordered as accessories.

Cable entry Cable-

[mm]

Sealing insert

Colour

Article number

(accessory)

Terminal casing

BC

4 – 6,5

6,5 – 9,5

yellow

black

1702200001

1702500001

Terminal casing

LC

4 – 6,5

6,5 – 9,5

yellow

black

4921000053

4921000050

2. Operating Conditions

The materials of the rod-type level probe and the temperature sensor

must be chemically resistant to the liquid to be monitored and must

be able to withstand the temperature of the liquid.

The ambient temperature at the terminal housing may not exceed

50 °C. Neither the terminal housing nor the cable may be immersed

in the liquid.

The probe may be used with reservations in liquids with a tendency

to form crystals or encrustation..

Rod-type level probes made of metal may, if necessary, be cut to the

required length by the user.

Universal rod-type probes made of PTFE may not be shortened.

Operating temperatures

•For metallic probe rods with PO sheath (black): 70 °C

•For metallic probe rods with PTFE sheath (translucent): 90 °C

•For probe rods sheathed with PTFE (white): 100 °C