Point / point average :

This function allows to calculate the average value of various points which you will have validated. The

s allows to validate a point or to reach the average of points previously validated. To

validate a point, press on the knob. Validate as many points as necessary, then by means of the knob,

choose "Average" and validate. The screen shows then: average(s), count of validated points, minimum

value(s), maximum value(s) and . To show the values of the various points, press

on the knob. Press then on " ESC ": once to return to the previous display, twice to begin another

calculation and three times to go out of the menu "point / point average".

crolling down menu

standard deviation(s)

Automatic point / point average :

This function allows to calculate the average value of various points, calculated themselves on a

duration beforehand defined.

It is necessary to choose at first the duration on which will be calculated each of the points;

and validate every number by pressing on the knob. Once the

duration validated, the scrolling down menu gives you access to the validation of points and to the

average. Proceed then in the same way as for the calculation of "average point / point" (previous

paragraph).

browse the

figures by scrolling down the knob

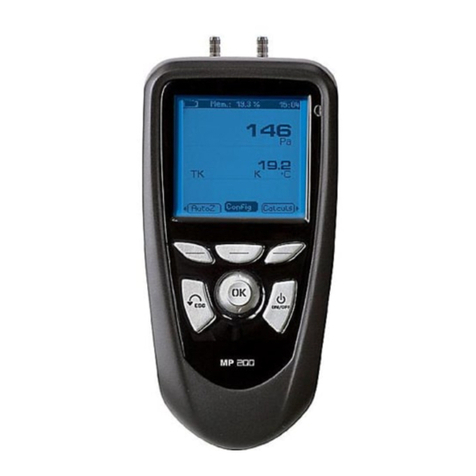

Airflow with Pitot (see connection of the Pitot tube p.7) :

When you enter in this menu, it is necessary to begin by selecting the type of diffuser : rectangular or

circular

validate. Enter

the length of the diffuser.Browse each figure by scrolling down the knob and validate pressing on the

knob ( to return to the previous figure, press on “ESC”). Proceed in the same way for the width.

You have access to a new scrolling down menu :

- Autozero (see p. 4)

- Units (see p. 5)

- Point/point average (see p. 6)

- Automatic point/point average (see p. 6)

- Temperature equalization (see p. 7)

- Rectangular :

by scrolling down the knob

browse then the units of measurement by scrolling down the knob and

6

Airflow with Debimo :

The principle is the same that the sub-menu “Airflow with Pitot” : Select the type of diffuser, the length and

the width or the diameter. The screen shows the following scrolling down menu :

- Autozero (see p. 4)

- Units (see p. 5)

- Automatic average (see p. 5)

- Temperature equalization (see p. 7)

- Circular : browse then the units of measurement by scrolling down the knob and validate. Enter the

diameter of the diffuser. Browse each figures by scrolling down the knob and validate pressing on the

knob. You have access to a new scrolling down menu :

- Autozero (see p. 4)

- Units (see p. 5)

- Point/point average (see p. 6)

- Automatic point/point average (see p. 5)

- Temperature equalization (see p. 7)