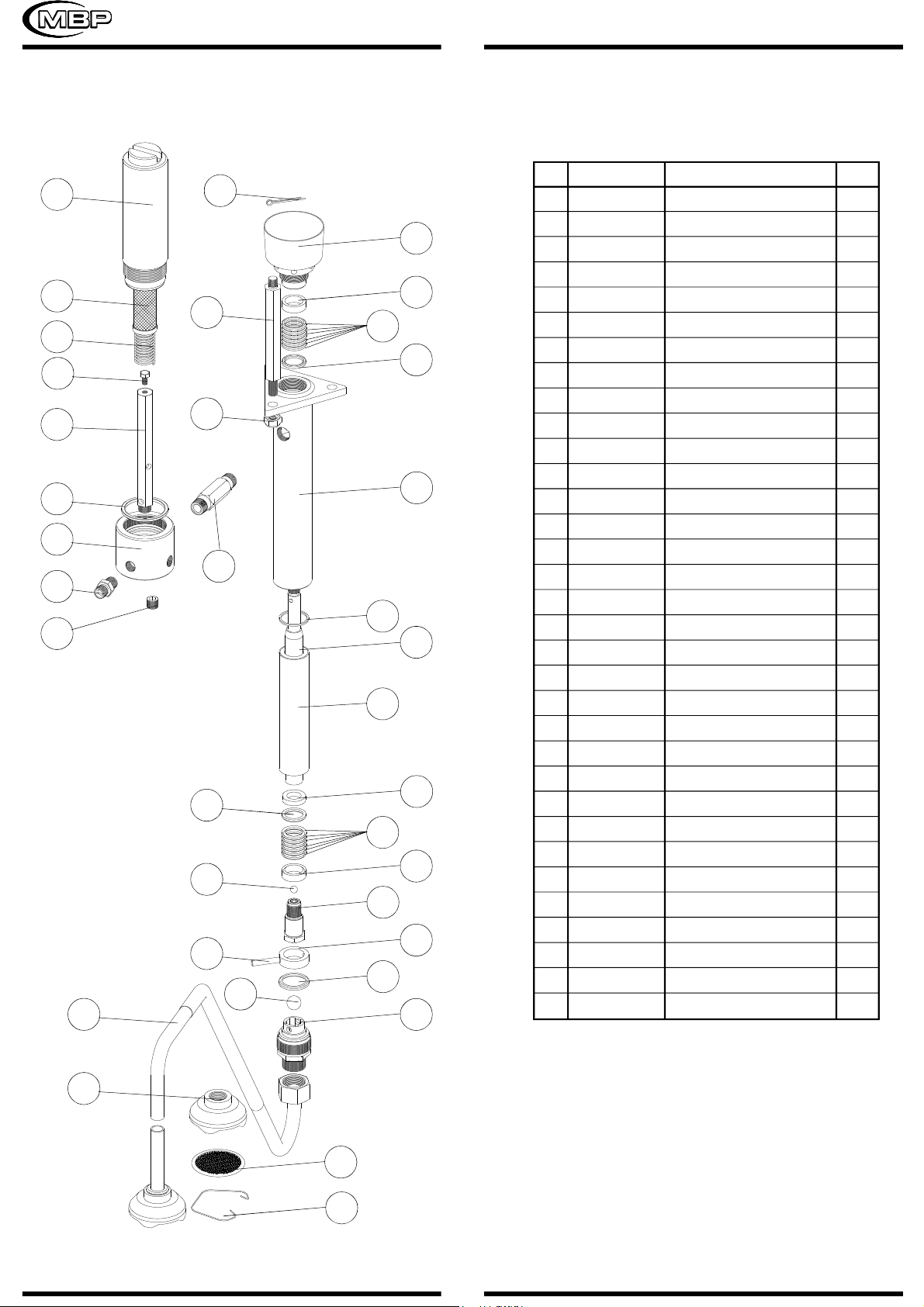

THROAT PACKINGS.

Screw the intake valve housing (20) out of the outlet

housing (8) and remove the piston and displacement rod as

explained to the left. Then screw the packing nut (3) out of the

housing (8) and take the packings (5) and glands (4, 6) out of

the cavity.

Install the throat packings as instructed below. Be sure

the lips of the v-packings face down, against fluid pressure.

Lubricate the packings with grease compatible with the fluid

being pumped. Always use new glands with the new packings.

One at a time, install a male gland (6), v-packings (5),

and a female gland (4) into the throat of the pump housing (8).

See fig.5.

Reassemble the pump in reverse order of disassembly.

Check the tie rods to be sure that they are tightened securely

into the air motor base. Assemble the connecting rod to the air

motor and screw the locknuts loosely onto the tie rods. Tighten

the packing nut until it´s just snug. Finish tightening the locknuts

evenly to 35-50 ft-lb (47-68 N.m) Then tighten the packing nut

just enough to stop leakage-no tighte. Start the pump and run it

at 40 psi (3 bar) minimum air pressure to check the tie rods for

signs of binding. Adjust if necessary.

Note:

If the grounding wire was disconnected before servicing, be

sure to reconnect it before operating the pump.

SERVICING THE AIR MOTOR

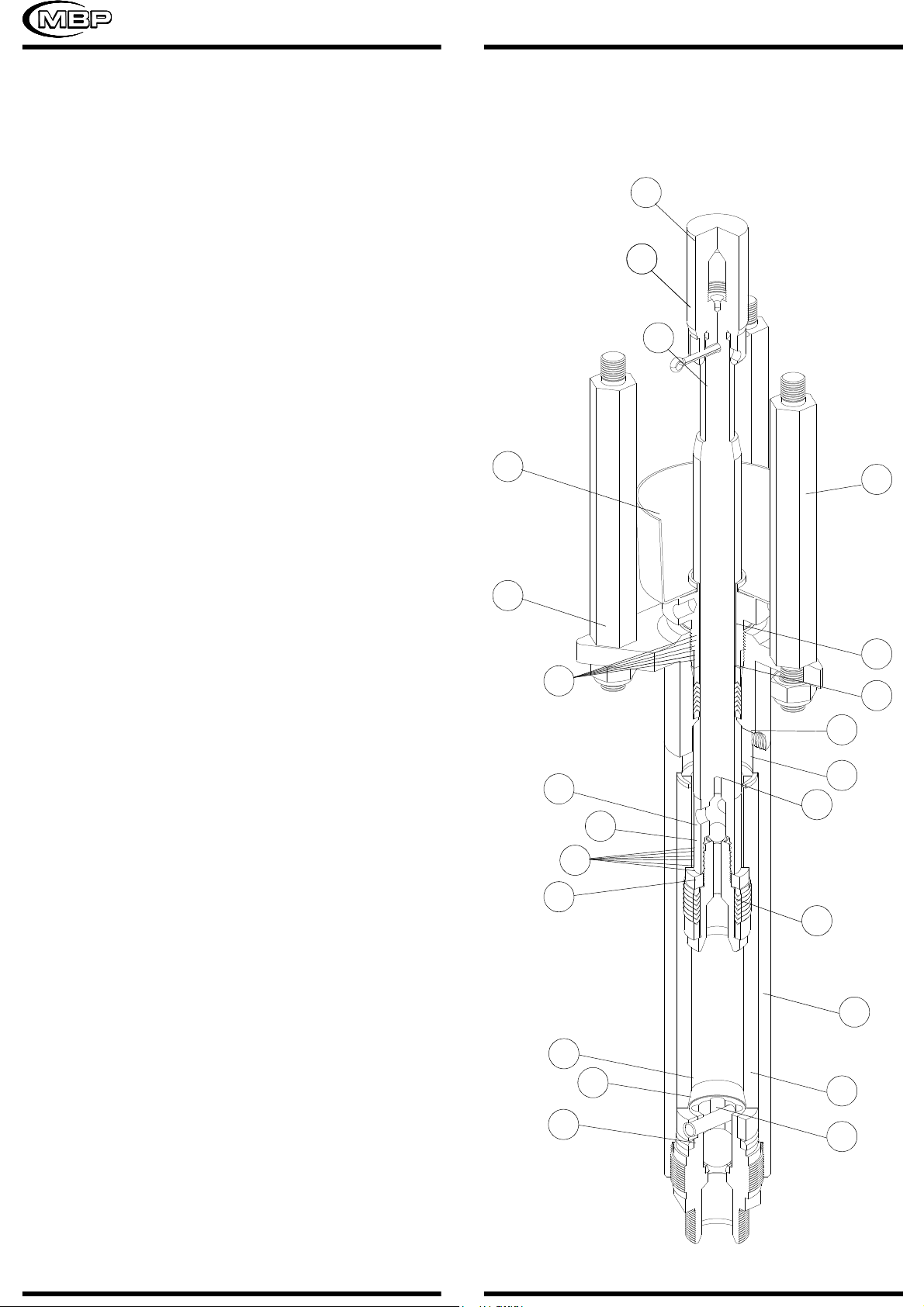

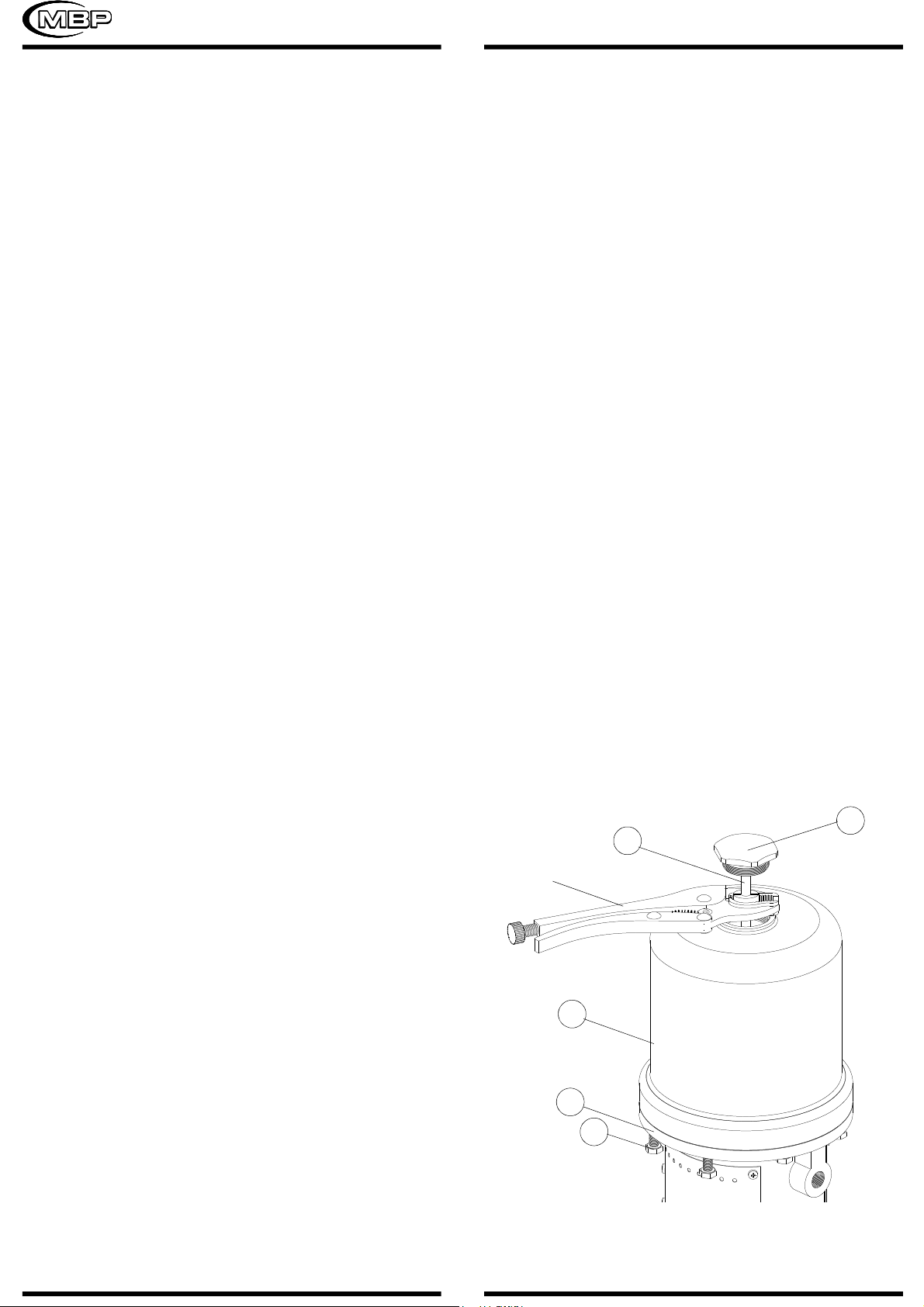

RESTARTINGA STALLED AIR MOTOR .

To reseat the air transfer valves and restart a stalled air

motor, relieve the air supply pressure to the motor by closing

the air valve. If the air transfer valves fail to reseat, screw the

cap nut (1) out of the cylinder (3), pull up on the trip rod (7)

and screw the cap nut back into the cylinder. See fig.6. Be sure

the air supply pressure is less than 12 bar (180 psi) before

opening the air valve.

DISASSEMBLING AND REASSEMBLING THE AIR

MOTOR.

Manually push on the piston rod to move the piston to

the top of its stroke. Screw the cap nut (1) out of the cylinder

(3). Pull up on the cap nut, grip the trip rod (7) with padded

pliers (A-A) and screw the cap nut off of the trip rod. See fig. 6.

Do not damage the plated surface of the trip rod.

Damaging the surface of the trip rod can result in erratic air

motor operation.

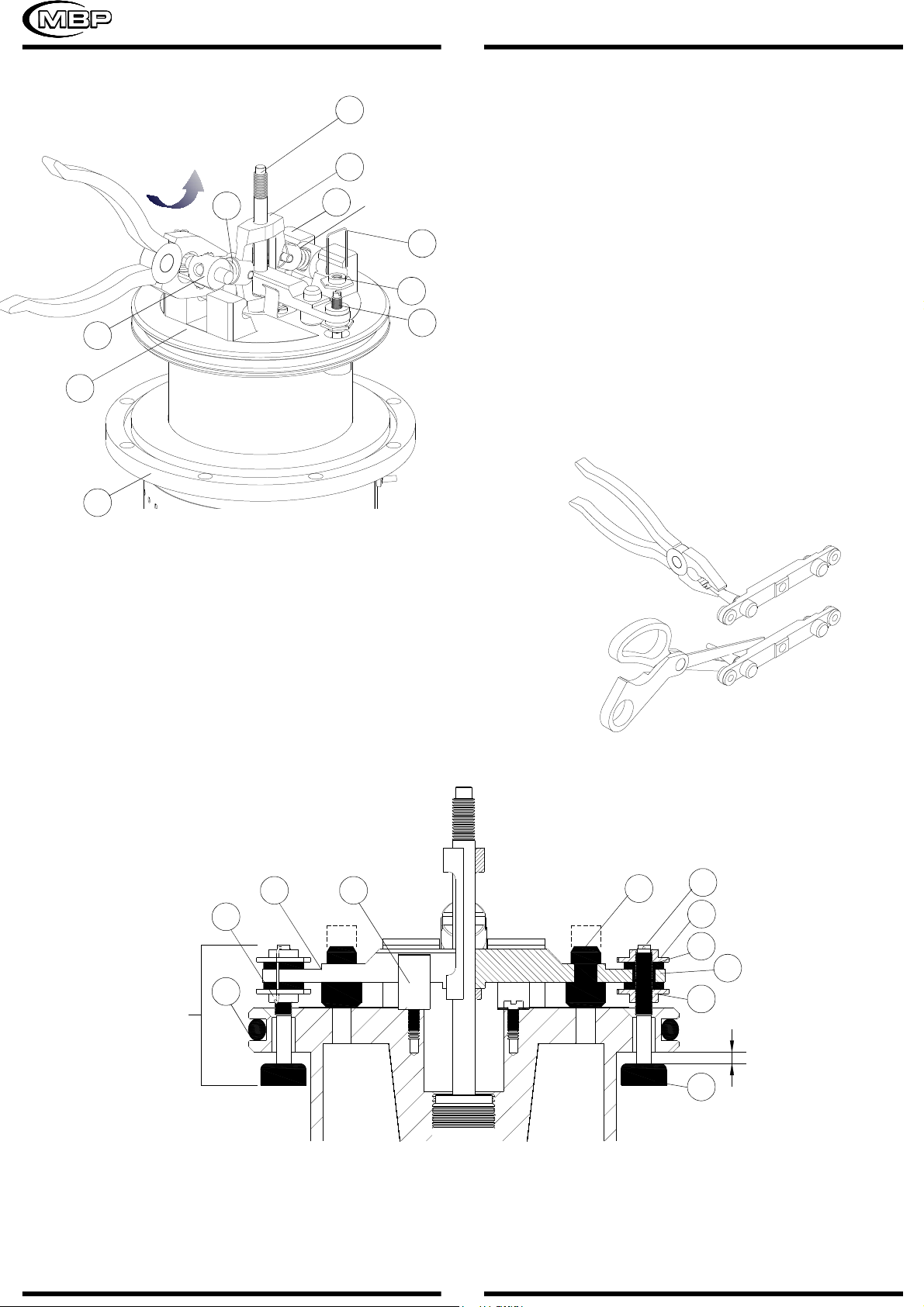

Remove the screws (19) holding the cylinder (3) to the

base (18) and carefully pull the cylinder straight up off of the

piston. See drawing 6. Always keep fingers clear of the toggle

assemblies (X), to avoid pinching or amputating them.

Use a screwdriver to push down on the trip rod yoke

(6) and snap the toggle assemblies (X) down. Remove the

lockwires (24) and upper adjusting nuts (25) from the air

transfer valves (H). Screw the valve stems (11) out of the

grommets (27) and lower adjusting nuts (25) and inspect them

for cracks. See fig. 7.

Grip the toggle rocker (21) with pliers, compress the

spring (22) , swing the toggle assembly (X) up and away from

the piston lugs (10) and remove the parts. See fig. 7. Inspect

the valve actuator (5) to be sure it is supported by the spring

clips (9), but slides into them easily. Remove the trip rod yoke

(6), valve actuator (5) and the trip rod (7). Check the exhaust

valve poppets (28) for cracks. Pull the piston (10) up out of

the base (18) and inspect the o-ring (12) in the base casting

(10).

To remove the exhaust valve poppets (28), stretch them

out and cut them with a sharp knife.

Clean all parts thoroughly and inspect for wear or

damage. Replace parts as necessary. Inspect the polished

surfaces of the piston, piston rod and cylinder walls for scratches

or wear. Lubricate all parts with a light waterproof grease. Be

sure the o-rings are in place, slide the piston rod down through

the troat bearing and lower the piston (10) into the base (18).

1

7

3

(A-A)

19

18

(fig. 6)