McConnel 5 Wheel Backing Gate Drive User manual

1

Owners Manual

McCONNEL

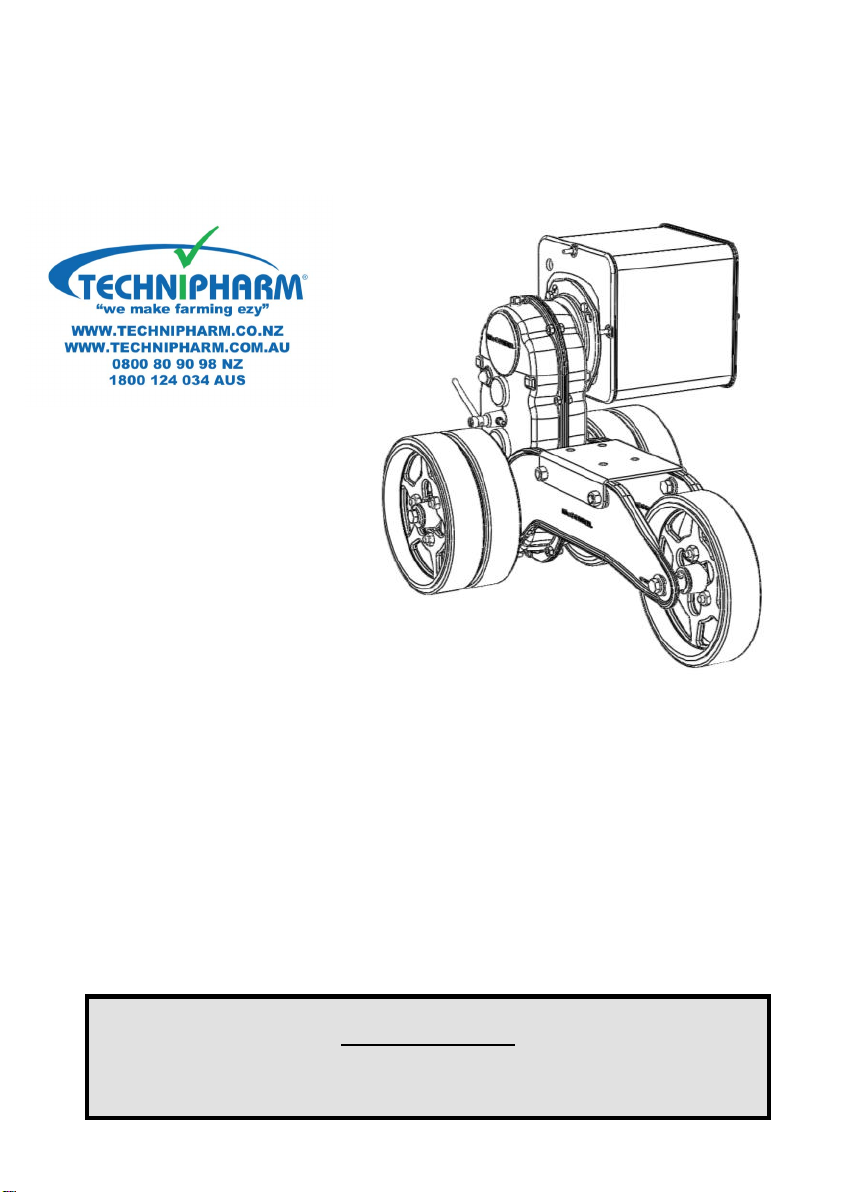

5 Wheel Backing Gate Drive

(Recommended for backing gates 10 to 14m long)

3-Phase and 1-Phase

Electric Powered

WARNING

Never operate your backing gate with people in the yard.

2

Limited Warranty

K H McConnel Ltd. (McConnel) warrants to the purchaser of a new Gate Drive Unit, that it will be free from

defects in material and workmanship for a period of one (1) year from the date of purchase, subject to the

following terms and conditions.

1. Remedies

During the limited warranty period McConnel or it’s authorised service agent will repair or replace, at

McConnel's option, any defective products or parts thereof with new or factory rebuilt replacement items.

All replaced parts or product shall become the property of McConnel.

Repaired product will be warranted for the balance of the original warranty.

2. Place of Repair

For repair under warranty the Gate Drive Unit must be returned to McConnel or their authorised service agent.

This warranty does not include freight, travel time or travel time associated with transporting the gate drive to or

from McConnel or their authorised service agent. No charge will be made for parts or the labour in repairing or

replacing the product.

3. Exclusions

The warranty does not apply if the Gate Drive Unit becomes faulty due to:

-Operation at voltages other than those shown on the motor name plate.

-Improper installation

-Misuse

-Neglect

-Accident

-Act of God

-Unauthorised repair or modification

-Service performed by other than competent persons

The warranty also does not apply if the purchaser fails to:

-Obtain a “warranty service authorisation number” from McConnel prior to having remedial work done.

-Notify McConnel within the warranty period.

4. Electric Motors

Proof of mains connection by a registered electrician is required for the warranty to include the electric motor.

This should be provided by your electrician at the time of installation.

This warranty only covers new electric motors supplied and fitted by McConnel to the Gate Drive Unit.

5. Wheels

The limited warranty covers the bond of the rubber to the rim and the rim only. No warranty is given on the life

of the rubber itself.

6. Limitation of Liability

McConnel accepts no responsibility for consequential loss, damage or injury to person or property arising from

any defect in the Gate Drive Unit or the installation to which it is connected.

7. Making a Warranty Claim

Should a fault occur during the warranty period, the purchaser must in the first instance telephone McConnel

(+64 7 849 2122) to obtain a “Warranty Service Authorisation Number”. The following information will be re-

quired; a. Purchasers name

b. Physical address where the gate drive is installed

c. Serial number of the Gate Drive Unit (Top of the gear casing opposite oil filler plug)

d. Place and date of purchase

e. Installing electrician if electric powered.

After discussion of the problem and available local service agents McConnel will initiate servicing under the

terms of this warranty.

3

Contents

Safety Pg 4

Installation Requirements

Yard Design Pg 4

Gate Design Pg 4

Gate Drive Installation

Mounting the Gate Drive Pg 5

Front Wheel Alignment Pg 5

Lubrication Pg 5

Electrical Supply and Wiring Pg 9

Optional Overload Clutch Adjustment Pg10

Spare Parts Diagrams

Gate Drive Exploded View Pg 6

Gear Casing Exploded View Pg 8

Motor Assembly Exploded View Pg 9

Operating Instructions

General Pg11

Free wheel clutch operation Pg11

Maintenance

Monthly Maintenance Pg12

Wheel replacement Pg12

Oil Change Pg12

Optional Overload Clutch Pg12

Warning: All gate drives are shipped without oil.

Please fill the gear casing to the sight glass

with (approx. 4 litres) SAE EP 90 grade gear oil

before use.

4

Safety

Never operate your backing gate with people in the yard.

McCONNEL backing gate drives are designed to move heavy

animals. If people are accidentally subject to the same loads,

serious injury may result.

Your holding yard should be designed to avoid trap points

where an animal may become trapped between the backing

gate and a fixed object.

Installation Requirements

Yard Design

The Gate drive unit is designed for operation on a circular or semi cir-

cular concrete surface with an even drainage fall, free of steps or

drainage channels. An uneven surface can cause premature failure of

the wheels and stop the gate from moving by lifting the drive wheels

off the ground.

Gate Design

The backing gate should be of sturdy construction capable of with-

standing the bending and torsional loads that will be applied to it. For

animal safely care should be taken to avoid diagonal bracing where a

cow may get its leg trapped in the vee that is created.

Putting a hock rail on the gate is recommended. This is a rail the

length of the gate that protrudes in front of the gate at a height of 500

to 600mm above the ground (depending on cow size and breed) that

prevents cows from holding the gate up with a straight leg. The hock

rail should not be too low or the cows lower leg and feet may be dam-

aged.

Ensure the motor or pelton wheel and freewheel clutch lever are ade-

quately protected from damage if cows are held on both sides of the

gate.

5

Gate Drive Installation

Correct attachment and alignment of your gate drive will greatly re-

duce the maintenance required over the life of your backing gate.

Mounting the Gate Drive

Position the assembled gate drive under the backing gate, within 1m

of the moving end with the drive wheels behind the gate away from the

cows being crowded. Position the gate across the centre of the mount

saddle and align the rear wheel shaft with the center post with the aid

if a string line (see figure 1). Double check alignment before welding

the mount saddle securely to the gate. The mount saddle is 255mm

above ground level.

Front Wheel Alignment

Next align the front shaft with the center post. Do this by lifting the gate

in a safe manner, until the front wheel is just clear of the ground.

Loosen the front shaft mount bolts and using a string line from the cen-

ter post as a guide, align the front wheel shaft so it points directly to-

wards the center post (see figure 1). Tighten the front shaft bolts and

lower the gate to the ground again.

Lubrication

All gate drives are shipped without oil.

Please fill the gear casing to the sight glass with

(approx. 4 litres) SAE EP 90 grade gear oil before use.

The filler plug is located on top of the gear casing.

Figure 1: Gate drive attachment to gate and alignment of wheels

Center Post

Mount

Saddle

Front shaft alignment

Rear shaft alignment

6

Gate Drive Exploded View

7

8

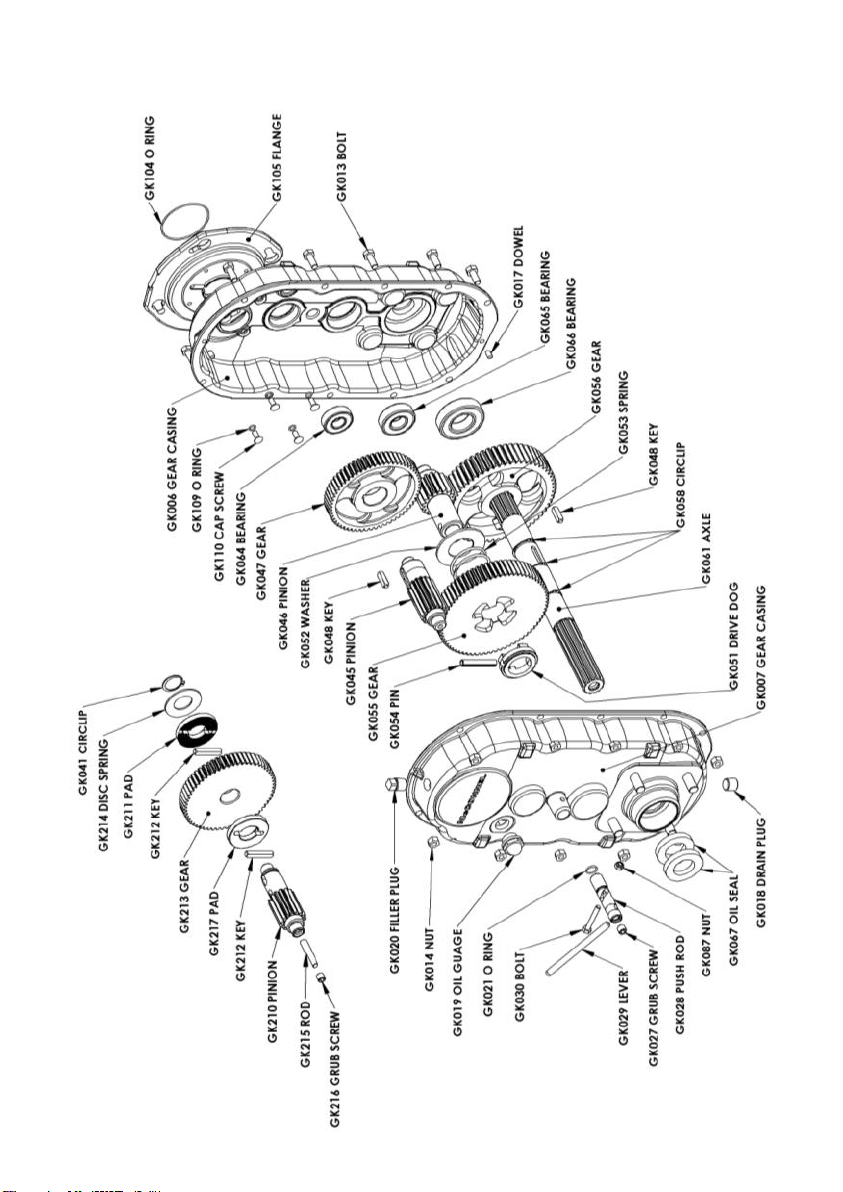

/ GK008 GEAR CASING WITH OPTIONAL OVERLOAD CLUTCH

Optional

Overload Clutch

Replaces GK047 GEAR

and GK045 PINION

Gear Casing Exploded View

9

Motor Assembly Exploded View

Electrical Supply and Wiring

Three phase motors are dual voltage and can be configured for use on

the following three phase power supplies;

230v 50Hz (1.9A) or 260v 60Hz (1.9A), delta connection.

400v 50Hz (1.1A) or 460v 60Hz (1.9A), star connection.

Be sure to install the terminal connectors correctly for star or delta

connection in accordance with motor name plate and instructions on

the motor terminal cover.

Single phase motors should only be connected to a 230v 50 Hz power

supply.

To prevent moisture entering the motor from the wiring;

If the conduit is terminated at the cast cover, the cable must be

sealed at the motor terminal box to IP55 specifications.

If the conduit is terminated at the motor terminal box, the entire

conduit including both ends must be sealed to IP55 specifications.

10

Water Supply

A suitable water supply must be available for the entire milking season

at a water pressure of approx. 40 psi (2.75 bar) and flow rate of 20 gal-

lons per minute (90 l/min) at the gate drive. Each water wheel on the

gate drive has a nozzle with a 25mm tail to attach the water supply to.

The supply line should be made self draining to prevent freezing in

cooler areas.

When run off a pressurised water supply, the gate drive can be con-

trolled by operation of a simple ball valve or a solenoid valve. Where a

pump is required the gate drive can be controlled by the pump starter.

For two-way water powered gate drives, it is convenient to have two

supply lines and select the forward or reverse supply form the milking

shed.

The power of the gate drive can be adjusted by restricting or increas-

ing the water flow to the gate drive. For example, reducing water flow

can reduce excessive wheel spin.

More predictable and convenient control is possible with a purpose

built controller such as a McConnel ‘Guardian’ Backing Gate Control-

ler.

For 3/4 circle yards a loop of flexible hose at the center post gives

enough movement to prevent the feed hose kinking through the gates

travel. For full circle yards, as when two gates are used in one yard, a

center post gland such as a McConnel 2” Wash Union will be required.

Operating Instructions

For 3/4 yards, a loop of flexible cable (approx 1m) is needed at the

transition from centre post to the gate, to reduce the bending stress on

the cable and prevent the cable cores breaking down. This loop must

be suitably supported and protected. For full circle yards, where the

gates are able to continue the next rotation without reversing, an elec-

trical slip ring at the center post is recommended.

A simple forward-off-reverse switch can be used to operate the back-

ing gate from one location in the shed or a combination of selector

switch for forward-reverse and pull switch for on-off will enable opera-

tion from any location in the pit. More predictable and convenient con-

trol is possible with a purpose built controller such as a McConnel

‘Guardian’ Backing Gate Controller.

Optional Overload Clutch

This gate drive can be fitted with an optional friction overload clutch for

added safety during milking.

Adjustment is done from outside the gear casing as follows:

1. Ensure the oil level is up to the sight glass.

2. Chain the end of the backing gate securely to a yard post with the

gated drive wheels on a clean yard.

3. Remove the overload cover plug (GK016) from the gear casing.

See Figure 2 on page 11.

4. Insert a 5mm AF Allen key into the adjusting screw and turn it anti

-clockwise until all tension is released from the clutch.

Caution: For safety, always stand behind the backing gate for

parts 5 to 8 of this procedure.

5. Get an assistant to start the gate drive in the forward direction.

6. Turn the Allen key clockwise to slowly tighten the clutch until the

electric motor starts to stall or the drive wheels begin to slip and

stop the gate drive. Note: the Allen key will rotate if the wheels slip

on the yard.

7. Turn the clutch adjustment back a 1/8th turn anti-clockwise.

8. Replace the cover plug taking care not to over tighten it.

9. Finally untie the gate.

Adjustment is required before use.

11

Operating Instructions

General

A backing gate is intended to prompt cows into the milking shed. To do

this it is recommended that the gate be used in short frequent move-

ments to prevent overcrowding in the yard. The backing gate should

never be left crowding cows that cannot move.

Free Wheel Clutch

All gate drives are fitted with a free wheel clutch to allow manual

movement of the gate. The clutch must be fully disengaged before

moving the gate manually or damage to the clutch may result. Also the

clutch should not be operated when the gate is in powered operation

or when the gate is being pushed.

Re-engage the clutch by releasing the clutch lever when the gate is

stationary and push the gate slowly until the clutch re-engages. Do not

start powered operation of the gate again until the clutch is fully en-

gaged.

Remove plug to

adjust overload

clutch

Figure 2: Overload Clutch Adjustment Location

12

Maintenance

Your gate drive is a robust unit designed to give many years of reliable

service if operated and maintained properly.

Monthly Maintenance

Check oil level and top up with SAE EP90 or equivalent grade

gear oil as required.

Grease front wheel bearing.

Check wheel wear. Replace the rim if it is worn down to the

aluminium. Failure to replace wheels at this time may result in

permanent damage to the gear casing.

Check for any loose fasteners or damage.

Wheel Replacement

It is recommended that the drive wheels be replaced as a set to pre-

vent uneven loading on the gate drive unit.

Oil Change

Change oil every 5 years or if milky due to water contamination.

Optional Overload Clutch

Adjust yearly or if the gate drive looses power. Instructions on Pg 10.

Manufactured and distributed by;

K. H. McCONNEL Ltd

666 Te Rapa Road

P O Box 10-334

Hamilton 3241

New Zealand

Phone: +64 7 849 2122

Fax: +64 7 849 2128

Email: sales@mcconnel.co.nz

Table of contents

Other McConnel Gate Opener manuals