Sentex SW2200 User manual

Doc 01-G0181

Rev A

Installation Instructions

Swing Gate Operator

Model SW2200

2Contents

Doc 01-G0181

Rev A

Contents

Safety Information______________________________________________ 3

Definitions _____________________________________________________________ 3

Important Safety Information _______________________________________________ 3

Classifications___________________________________________________________ 5

Specifications__________________________________________________ 6

Mechanical _____________________________________________________________ 6

Electrical_______________________________________________________________ 6

Site Preparation _______________________________________________ 10

Pad Mounting __________________________________________________________ 10

Installation___________________________________________________ 11

Mechanical ____________________________________________________________ 11

Electrical______________________________________________________________ 13

Basic Setup and Device Connections ______________________________ 14

Setup ______________________________________________________________ 14

Device Connections _____________________________________________________ 16

Operator Programming Menu (LCD Screen)________________________ 17

Definitions and Options __________________________________________________ 17

Troubleshooting_______________________________________________ 19

Diagnostic Screen_______________________________________________________ 19

Entrapment Adjustment __________________________________________________ 20

No Position or Speed ____________________________________________________ 20

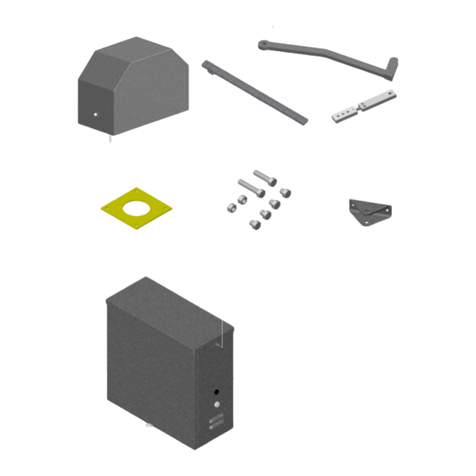

Replacement Parts Assembled____________________________________ 21

Parts List______________________________________________________________ 22

Maintenance _________________________________________________ 23

Cold Weather Operation__________________________________________________ 23

Appendix ____________________________________________________ 24

Wire Sizes and Distances _________________________________________________ 24

Non-Standard Installation_________________________________________________ 24

Safety Information 3

Doc 01-G0181

Rev A

Safety Information

Definitions

ENTRAPMENT

The condition when an object is

caught or held in a position that

increases the risk

of injury.

CAUTION

Indicates a potentially hazardous situation

which, if not avoided, may result in minor

or moderate injury. It may also be used to

alert against unsafe practices.

DANGER

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

This signal word is to be limited to

the most extreme situations.

WARNING

Indicates a potentially hazardous

situation which, if not avoided,

could result in death or serious

injury.

NOTE

DANGER or WARNING should not

be considered for property damage

accidents unless personal injury risk

is appropriate to these levels is also

involved.

CAUTION is only permitted for

property damage accidents.

PASSPOINT

A reference point to set/find open/close

limits. When gate reaches passpoint, PP

LED blinks.

Important Safety Information

WARNING

Read and follow all instructions.

TO REDUCE THE RISK OF INJURY OR DEATH . . .

Never let children operate or play with gate controls. Keep the remote

control away from children.

Always keep people and objects away from the gate. No one should cross

the path of the moving gate.

Test the gate operator monthly. The gate must reverse when any safety

device is activated. After adjusting or setting limits of an operator, retest the

gate operator. Failure to adjust and retest the gate operator properly

can increase the risk of injury or death.

Use the emergency release only when the gate is not moving.

Keep gates properly maintained. Read the owner’s manual. Have a

qualified service technician make repairs to gate hardware.

The entrance is for vehicles only. Pedestrians must use separate entrance.

Save these instructions!

4Safety Information

Doc 01-G0181

Rev A

INSTALL THE GATE OPERATOR ONLY IF . . .

The operator is appropriate for the construction of the gate and the usage

class of the gate.

All openings are guarded or screened to prevent access by arms or legs

through openings anywhere in the gate.

All exposed pinch points are eliminated or guarded.

The operator is intended only for installation on gates used for vehicles.

Pedestrians must be provided with a separate access opening.

NOTES: The gate must be installed in a location so that sufficient

clearance is provided between the gate and adjacent structures when

opening and closing to reduce the risk of entrapment. Swinging gates

should not open into public access areas.

The gate must be properly installed and work feely in both directions prior

to the installation of the gate operator.

NON-CONTACT SENSORS (E.G., PHOTOCELL)

Read the following for gate operators utilizing non-contact sensors:

See instructions on the placement of non-contact sensors for each type of

application.

Exercise care to reduce the likelihood of nuisance tripping.

To prevent gate entrapment, install non-contact sensors on both sides of

the gate to cover the gate perimeter during closing and opening.

LOOP VEHICLE DETECTORS

Read the following for gate operators utilizing loop vehicle detectors:

WARNING

Loop Detectors do not provide protection for people! Loops should

only be used for vehicular control.

Follow manufacturers instructions for loop installation.

Gates can be made of metal and will therefore react with the loop system,

creating false tripping. Please note loop manufacturer’s recommendations

for minimum gate clearance.

Loop sense wiring must be secure within its ground track. Loose wiring will

cause false triggering. Leader wires from the loop track to the detector

must be wrapped 5 times per foot minimum to prevent false tripping.

Safety Information 5

Doc 01-G0181

Rev A

Classifications

CLASS I

Residential Vehicular Gate Operator

A vehicular gate operator (or system) intended for use in a home or one-to-four

single family dwelling, or a garage or parking area associated therewith. Required

additional equipment—Type B1 non-contact sensor.

CLASS II

Commercial/General Access Vehicular Gate Operator

A vehicular gate operator (or system) intended for use in a commercial location or

building such as a multi-family housing unit (five or more single family units) hotel,

garages, retail store, or other building servicing the general public. Required

additional equipment—Type B1 non-contact sensor, or Type E—an audio alarm.

CLASS III

Industrial/Limited Access Vehicular Gate Operator

A vehicular gate operator (or system) intended for use in an industrial location or

building such as a factory or loading dock area, or other locations not intended to

service the general public.

CLASS IV

Restricted Access Vehicular Gate Operator

A vehicular gate operator (or system) intended for use in a guarded industrial

location or building such as an airport security area or other restricted access

locations not servicing the general public, in which unauthorized access is

prevented via supervision by security personnel.

6Specifications

Doc 01-G0181

Rev A

Specifications

Mechanical

GENERAL SPECIFICATIONS

Overall Size Weight

19”L x 23”W x 31”H 190 Pounds

Table 1

GENERAL CONSTRUCTION

Electroplated, welded steel frame with

a dual gearbox reduction of 600:1 and

an ultimate strength of 2,000 foot

pound. The cover is UV durable

plastic.

GATE CAPACITY

This operator is designed for maximum

size gates. In general, the operator may

work with any gate below 1000 pounds

and 22 feet, with low wind resistance,

sturdy construction, and good hinges.

Electrical

Always use a qualified electrician and follow your local construction codes when

connecting power. General guidelines are:

Line voltage required is 115 VAC

(10% [103-127]) single phase. Wire size, accessory power (18-gauge

recommended).

Line amperage Required 15 Amps

Max. Device controls - any insulated wire can

be used (18-24 gauge recommended).

Wire size, operator power – see

Wire Sizes and Distances on

page 24.

NOTE: The operator is permanently

wired; it does not use a grounding plug.

ELECTRICAL BOX

See Figure 1. Stamped aluminum housing for the processor, motor VFD drive, and

front panel PCB's. For factory repair, the complete panel can be quickly removed

and replaced.

CAUTION

Do not repair or open box!

There is a potential shock

hazard from the High Voltage

capacitor! Danger exists even

when power is disconnected!

Specifications 7

Doc 01-G0181

Rev A

Figure 1

PROGRAMMING

Programming is accomplished with a 5 button, 2 LED membrane switch located on

top of the control box. Programming instructions are presented on a 2 row, 16

character LCD screen (see Figure 2).

Sentex

systems

01-16169F1

Figure 2

DEVICE CONNECTIONS

Connections are made to the lower half (exposed half) of the front panel PCB.

Provisions are made for:

J2 – Safety edge open (trailing edge contact

sensor); N/O & N/C J8 – Hold open (no timer); Single Button

J3 – Safety edge close (leading edge contact

sensor); N/O & N/C J9 – Photo eye (non-contact sensor); N/O

& N/C Contacts

J4 – 3 loop detectors JP5, JP6, JP7, & JP8 – Output relays for

lights, etc.

J5 – Close; Open w/ Timer JP5, JP6, JP7 – Master/Slave connections

J6 – Not Used

J7 – Stop (required N/C connection)

JP9 – 24 VDC power

JP12 – 24 VAC power

JP14 – 115 VAC power

8Specifications

Doc 01-G0181

Rev A

01-20211F1

(NO)

CLOSE

(NO)

OPENW/

TIMER

Figure 3

MASTER/SLAVE CONNECTIONS (OPTION)

Sentex Systems recommends18-20 gauge wire for the minimal wattage required to

run a pair in master/slave setups.

WHITE

BLACK

CLOSE RELAY

STOP RELAY

OPEN RELAY

MASTER

RED GREEN

SLAVE

J7

STOP

J8

J5

(NC)

STOP

J8

HOLDSINGLE

OPENBUTTON

01-20211F2

COM

COM

COM

COM

COM

COM

Figure 4

Specifications 9

Doc 01-G0181

Rev A

FULL BATTERY BACKUP (OPTION)

24 hours continuous operation with normal use of accessory! This is the only

operator offered with transparent battery backup.

Site Preparation 10

Doc 01-G0181

Rev A

Site Preparation

Pad Mounting

For pad mounting instructions, perform the steps below and refer to the Figures below.

AVAILABLE CABLE

ENTRY ZONE

(Keep All Conduits

Within Shaded Area)

4.50

1.37

1.50

3.25

0.75

TYP. 13.50

15.00

21.00

1/2” ANCHOR BOLTS

FOUR (4) PLACES TYP.

COVER

OUTLINE

01-G0181F5

Figure 5

1”

6” min.

01-G0181F6

Figure 6

1Excavate to the depth required by

local code or below frost line.

2Situate pad according to Figure 7.

3Using a license and qualified

electrician, route wiring for operator

power and controls prior to pouring

concrete. Situate conduit on pad

as shown in Figure 5.

4Pour concrete ensuring that the

pad is level and, 2" to 4" above

ground line.

5Sink (4) 1/2" x 6" minimum length

L-bolts (not supplied) as detailed in

Figure 6and Figure 7. The bolts

should protrude 1" above the pad.

The shipping crate bottom may be

used as a bolt pattern template.

6Allow concrete to set for 2 days

before installing operator.

7If there is existing concrete on the

site, use 1/2" anchor bolts (not

supplied) to secure the unit. If

needed, use washers to shim the

operator level with the gate.

NOTE: Local Codes - This

manual does not supersede

local codes for construction,

and was written to be used by

a qualified and licensed

electrician.

For non-standard installations or

retrofit applications, see Non-

Standard Installation on page 24

for instructions.

GATE

HINGE PIN

COLUMN FENCE

21.00

13.50

OPERATOR

SHAFT

LOCATION

CABLE ENTRY

ZONES

ANCHOR BOLT

LOCATION

4.75

35.75

40.50

7.50

01-G0181F7

Figure 7

11 Installation

Doc 01-G0181

Rev A

Installation

Mechanical

Only qualified contractors experienced with mechanical installations and the hazards

associated with them should perform the following instructions.

1Ensure all power is disconnected.

2Prepare the site (see Site Preparation, p. 10).

3Pull and label wires for power and control.

4Bolt operator in place (see Figure 8). Use washers to level operator.

5Attach Crank arm (see Figure 9).

01-G0181F8

Figure 8

01-G0181F9

Figure 9

6Attach gate bracket at fence 31” from top of pad (see Figure 10) and

approximately 36” from gate hinge.

5”

31”

+/-

½

Gate

01-G0181F10

Figure 10

12 Installation

Doc 01-G0181

Rev A

7Adjust length of crank arm (LC) to 25-1/2” (see Figure 11) and length of

extension arm (LE) to 44” (see Figure 12).

LC

25-1/2”

STANDARD

OPERATOR

CRANKSHAFT

CENTERLINE

01-G0181F11

Figure 11

LE

44”

STANDARD

01-G0181F12

Figure 12

8Modify the lengths and the gate bracket position so the crank and extension

arms lineup when the gate is closed (see Figure 13).

OPTIMUM CLOSED POSITION

01-G0181F13

Figure 13

9Open gate with quick disconnect (see

Figure 9)and manually swing gate to the

open position.

10 When open, the gate should travel at

about 95 degrees, and the crank arm

should overlap (parallel) the extension

arm (see Figure 14).

11 Lubricate gate pivot and elbow joint with

medium weight lubricant, superlube or

equivalent.

NOTE: For non standard or retrofit

installations, see page 24 for

custom installation instructions.

OPTIMUM OPEN POSITION

01-G0181F14

Figure 14

Installation 13

Doc 01-G0181

Rev A

Electrical

1Turn off line power (at the circuit breaker/panel) and operator (operator switch

to off).

2Attach power wiring (L1, L2, and ground).

3Apply line power (115VAC). Check to see if the pilot light is on and the

operator power switch is still off. Check if operator does not run, beep or

function, and LED's are off.

4Turn operator on. Listen for 2 beeps. The LCD should read “LIMITS MENU”.

NOTE: If limits have been previously set, the menu will read

"OPERATION NORMAL", with the status displayed underneath it.

CAUTION

If you do not know the limit settings, reset limits according to the Basic

Setup and Device Connection chapter, starting on p. 14.

01-G0181F15

Figure 15

Basic Setup and Device Connections 14

Doc 01-G0181

Rev A

Basic Setup and Device

Connections

Setup

WARNING

Use only qualified electricians. Serious injury or death can occur from

electrical shock or entanglement in operator.

NOTE: Follow manufacturer’s instructions for safety devices such as edges

and photo eyes.

UNLOCKED

LOCKED

01-G0181F16

Figure 16

1Install the stop button (normally closed)

on J7 terminals. The operator will not

run without this button.

2Turn off line power and battery power.

3Release (unlock) the quick disconnect

(see Figure 16) and check that the gate

swings freely.

4Lock quick disconnect (see Figure 16).

5Turn line power on. The LCD screen

should display the "Limits Menu" if limits

have not been set.

CAUTION

The unit should not move. If it does,

shut off power and check all

connections before proceeding.

NOTE: The operator is shipped from the

factory without limits. If limits have been

previously stored, the men will read

“OPERATION NORMAL”.

6Check to see that the Limits’ LEDs are

off.

7See Figure 17. Screen should read

“LIMITS MENU”; press enter and + to

set limits.

8Using the {+/-} buttons, run gate to the

closed position (crank and extension

arms to be lined up) and press enter to

set the close limit.

Sentex

systems

01-16169F1

Figure 17

Basic Setup and Device Connections 15

Doc 01-G0181

Rev A

9If during testing, the gate stops or

reverses due to entrapment, adjust

the entrapment settings (see the

SLMAX/SW2200 Programming

Manual).

PUSH TO

ENGAGE

GEARS

PULL TO

DISENGAGE

GEARS

PASSPOINT

LED

01-G0181F17

Figure 18

10 Using the {+/-} buttons, run gate to

the open position. stop when

passpoint LED flashes (see Figure

18).

11 If passpoint is near the center of

crank arm travel (see Figure 19)

continue to step 12.

If passpoint is not near

center, loosen (2) nuts with

1/2” wrench.

Using the {+/-} buttons, run

gate to center position.

Re-engage the passpoint and

tighten nuts.

12 Using the {+/-} buttons, continue

running gate to open position (crank

arm and extension arm parallel and

overlapped) and press enter.

13 LCD screen reads "PRESS ENTER

TO TEST". Now press enter and the

gate will self test by closing, opening

and closing. LED’s will flash until self

test is done and then will be

continually on.

Optimum

Passpoint

Location

CLOSED

OPEN

80%

20%

01-G0181F18

Figure 19

14 Run gate 5 times to test limits and

entrapment settings (25 from

factory). If during testing, the gate

stops or reverses due to entrapment,

adjust entrapment settings.

16 Basic Setup and Device Connections

Doc 01-G0181

Rev A

Device Connections

All electrical connections are made with a euro-connector for quick and easy

maintenance of the electrical box. You may make 95% of all accessory connections

with 18-24 gauge wire. Accessory power should be 16-18 gauge.

NOTE: Connect line power to the electrical box according to the instructions on

page 6.

NC (normally closed) terminals are required. That is, you must either connect them for

use or jumper them (non-use). The operator will not run without the NC terminals wired

to an NC device or otherwise shorted. These terminals are identified by safety bars

(see Figure 20).

J7 = STOP

J2 = SE OPEN (Safety Edge Open)

J3 = SE CLOSED (Safety Edge Closed)

J9 = PHOTO EYES

(NC)

EDGE

OPEN

(NO)

EDGE

OPEN

(NO)

EDGE

CLOSE

(NC)

EDGE

CLOSE

01-G0181F19

Figure 20

17 Operator Programming Menu (LCD Screen)

Doc 01-G0181

Rev A

Operator Programming Menu

(LCD Screen)

Programming occurs on a 5-button, 2-LED membrane switch located on top of the

control box (see Error! Reference source not found.). Programming instructions

appear on a 2-row, 16-character LCD screen.

NOTE: This chapter serves as an overview of the SW2200’s programming

functions and features. For more detailed instructions, refer to the

SLMAX/SW2200 Programming Manual.

Definitions and Options

GATE STATUS

The following status conditions will be displayed during normal gate operations:

Closed: Gate is in the closed condition and has not received any

commands to run.

Closing:

Midstop: Gate in any position other than closed or open and has not

received any run commands.

Opening: The operator has received a command to open and is opening

the gate.

Open: Gate is in the open condition and has not received any commands to

run.

LIMITS MENU

You may select the limits menu by scrolling thru the menu buttons. This menu will

be visible if the operator does not have limits already set (operators are sent from

the factory without limits).

NOTE: See Basic Setup and Device Connections for limit setting

procedures.

LOOP MENU

This feature allows you to program the desired loop function using the J4 inputs (A,

B, and C). Loop types include:

Open Loops

Safety Loops

Shadow Loops

TIMER TO CLOSE

This feature allows you to set the time (in seconds) the gate stays open prior to

closing automatically. Display time value [off, 0-120 seconds].

18 Running Header

Doc 01-G0181

Rev A

ELECTRIC LOCK DELAY

All gates installed with a maglock (connected to the JP6 connector/input) may have

the electric lock delay function programmed into the system. This delays the gate

from opening for a programmed number of seconds (1-10) when the operator is

prompted to open. After the delay, the operator will de-energize the maglock

(allowing the gate to unlock) and open the gate.

Display value of delay [off, 0-10 seconds].

GATE OPERATOR WARNING

This feature allows you to enable or disable the operator alarm that warns people

with beeps when the gate is moving. Display value of delay [off, 0-10 seconds].

RESET TO DEFAULT

Select Yes+/No- to reset operator to factory defaults.

SINGLE BUTTON

The Single Button (connected at the J8 input connector) programming feature

allows you to configure the single button function (i.e., how the gate reacts after you

press the single button).

Selectable options include the following:

GATE CONDITIONS PROGRAMMABLE FUNCTIONS POSSIBLE

STOP

OPEN ONLY

OPENING STOP, NO TMR RST

STOP

CLOSING REVERSE

MID-STOP OPEN

AT MID-STOP MID-STOP REVERSE

Table 2: Programmable Options

If the gate is and you select the gate will

STOP Stop. If “TIMER TO CLOSE” is activated

(see p. Error! Bookmark not defined.), the

gate closes after timer elapses.

OPEN ONLY Continue to open—does not allow you to

stop gate using single button.

OPENING

STOP, NO TMR RST Stop. If activated, “TIMER TO CLOSE”

function will not occur.

STOP Stop.

CLOSING REVERSE Stop and then reverse to the open position.

MID-STOP OPEN Travel to the open position.

AT MID-STOP MID-STOP REVERSE Close if the gate was previously opening.

Table 3: Single Button Functions

19 Troubleshooting

Doc 01-G0181

Rev A

Troubleshooting

Diagnostic Screen

The Diagnostic Screen is real-time screen displaying critical information for

troubleshooting the operator. Refer to Figure 21.

RELATIVE POSITION

This shows the position using the

passpoint as a zero reference. Each

value represents one hall effect count

or 1/12 of a motor revolution. This

value can be 4500 or higher.

COMMAND SPEED

The command velocity of the

processor, 0-222 max.

OPERATOR STATE

Shows the 5 stages of operation:

Open, Opening, Midstop, Close and

Closing.

HALL EFFECT

Symbol switches when hall sensor

trips > <.

TQ

Displays relative torque of the

operator.

PASSPOINT FLAG

“P” flashes upon seeing the passpoint.

“D” states that the entrapment is

disabled.

ENTRAPMENT MODE:

T = Normal torque measurement.

E = Indicates overtorque entrapment

has occurred.

P = Indicates a position entrapment

has occurred.

TQ LIMIT

Self adjusting limit that triggers TQ

entrapment. This value is different for

ramp up and ramp down and run.

LIMIT ACCURACY

This number represents the operator

and position relative to the open or

close limit. This number should be in

the range of +/- 10. The number will

be replaced by “**” if the operator and

position deviates by more than 20

counts.

ENTRAPMENT LEVEL

This represents the number of times

the operator has detected

entrapment.

01-G0181F20

Figure 21

20 Running Header

Doc 01-G0181

Rev A

Entrapment Adjustment

Changes sensitivity of the inherent entrapment system from off, 0-99. Increase value

until gate runs smoothly without false entrapment. 0 is the most sensitive and 99 is the

least sensitive. Set a nominal entrapment level of 25.

No Position or Speed

Verify with the Troubleshooting Screen (see page 19).

WARNING

Do not run system without hall sense (speed sense) for more than 1 minute, as

overheating will occur.

1Check sensor harness for connection and security (see Figure 22).

2Adjust sensor by loosening bracket screws and inserting sensor until it barely

touches the target disk inside the motor.

3If motor continues to surge or not run, adjust sensor again.

01-G0181F21

Figure 22

Table of contents

Other Sentex Gate Opener manuals