2

cedure” described in the Signo instructions manual (the set values

are saved in the memory).

04. Then position all Dip-switches to Off.

—— To adjust point RA ——

01. Set the Dip-switches as follows:

on -------4-------------- | -11----

off -1-2-3--5-6-7-8-9-10- | - -12-

02. Then follow steps 02, 03 and 04 illustrated above to adjust point

RC.

NEW SIGNO STARTING SIGNAL MODE

This new signal occurs when Signo is started and signals that the con-

trol unit is on and operating correctly.

To verify this, turn the control unit on and check that the five LEDs next

to terminals 16, 17, 18, 19, 20 and the “Led Ok” rapidly flash immedi-

ately for a few seconds. Then check that the “LED Ok” continues to

flash regularly every second: This indicates that the control unit is

operating correctly.

NEW AUTOMATIC DIAGNOSTICS FUNCTION OF

THE OPERATIONAL FAULTS

This new function performs the automatic diagnostics of faults that the

Control unit encounters during the automation’s normal operations, and

signals the problem through a determined number of flashes of the “LED

Ok” (the diagnostic flashes always refer to the last action performed by

Signo).

Refer to the following table to understand the meaning of the number of

“LED Ok” flashes:

Note (*): Flashed 6 and 7 are only possible on the Master-Control unit.

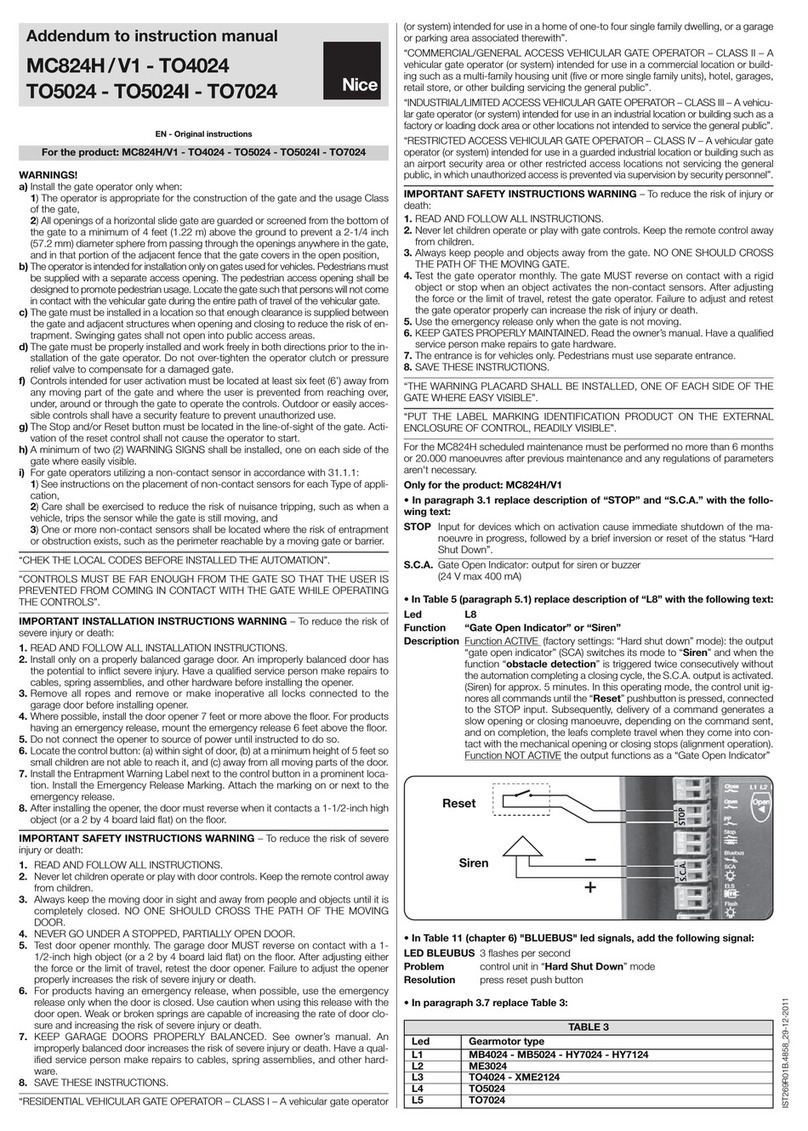

N°✺CAUSES

2= Input from “Photo” or “Phototest” error

3= Motor torque is not enough

4= Input from “Stop”

5= Error in Memory parameters

6* = Error in Signo-Slave

7* = Error in Signo-Master comunication

• Selection of the operational mode and Auxiliary Operations.

Only the “Electric lock/ Suction cup” operations can be select-

ed with Dip-switch 8 on the Slave-Control unit. The other modes

and operations must be selected on the Master-Control unit.

Note: If Buffer batteries are used, each automation must have its

own battery.

04. Apply power to each of the Control units once the various electrical

connections have been completed, and perform procedure “3.10 –

checking the connections”, described in the two Signo instruction

manuals, on each of the control units.

05. Complete the Signo-Master installation by carrying out the “Testing”

procedure described in the two Signo instruction manuals. Once

completed, leave dip-switch 12 in OFF (the Signo is assigned the

“Master” function with this setting).

06. Complete the Signo-Slave installation by carrying out the “5 - Test-

ing” procedure described in the two Signo instruction manuals.

Once completed, leave dip-switch 12 in ON (the Signo is assigned

the “Slave” function with this setting).

NEW PROCEDURE FOR THE PERSONALISATION

OF THE BAR’S “MOVEMENT DECELERATION”

Warning! – This new procedure replaces the “4.3 – Manual pro-

gramming of deceleration positions”, present in the Signo instruc-

tions manual.

This new procedure allows choosing a point along the trajectory of the

bar at which the control unit must decelerate the bar during the opening

and closing manoeuvre before its movement stops against the mechan-

ical stop.

In reference to Fig. 2, the distance in which the bar performs the “decel-

eration movement” is between points RA and 1(during opening)and

points RC and 0(during closure). The extent of these two distances is

automatically obtained by the control unit during the “4.1 – Mechanical

stop initial search” described in the Signo instructions manual. The val-

ues memorised during this search are defined in the factory on a scale

between 1and 6positions (1= approx. 6°):

– point RA = position 2(= approx. 12°);

– point RC = position 3(= approx. 18°).

The initial set positions can be viewed by means of the following proce-

dure that can be modified if necessary by increasing or decreasing the

position number for each of the two RA and RC points.

—— To adjust point RC ——

01. Set the Dip-switches as follows:

on -----3---------------- | -11----

off -1-2--4-5-6-7-8-9-10- | - -12-

02. – To INCREASE the value of 1 position, push button “T1 Open”

once (each time the button is pushed the “LED Ok” flashes the

same number of times as the positions set up to that point).

– To DECREASE the value of 1 position, push button “T3 Close”

once (each time the button is pushed the “LED Ok” flashes the

same number of times as the positions set up to that point).

03. Once the choice has been made, follow procedure “4.4 – Save pro-