I&WARNING: TO REDUCE THE ?QTENT’fAt- FOR ANY INJURY, COMPLY WITH THE FOLLOWING SAFETY

lNSTRUCTfONS. FAILURE TO COMpf-Y WITH THE lNSTRUCllONS MAY RESULT IN PERSONAL INJURY.

TRAINING

Read this owrmr”s manual carefully in fis entirey before

attempting to assemble or operate this machine. Be

completely familiar with the controls and the proper use of

thl.s machine before operai~ it. Keep this manual in a

safe pface for future and rqular reference or for ordering

replacement parts.

Children must never be allowed to operate this

equipment.

No one shoufd operate this unit while intoxicated or while

tafdng medication that imps.ks the senses or reactions.

This equipment shoukf never.be operated in the vicinity of

children, pets or other persons.

Never run your machine in an enclosed area as the

●exhaust from the engine contains carbon monoxide,

ydich Is an pcfdess, tasteless and deadly poisonous gas.

Never place your hands or any part of your bocfy or

cbthing inside the”feeding chamber, discharge chute, or

near any moving part while the machine or engine is

running.

If it’ Is necessary for any reason to irrsp&t or repair the

feeding chambers of any part of the macf&e where a

moving part can cqme in co”ntact with your body or

cbthirrg, stop the machine, aflow it to COOI,disconnect the

spark plug wire from the spark plug and move it away from

the spark plug before attempting such inspection or

repair.

PREPARATION

Wear safety gogglos, work gfoves and shoes while

operating the chipper/shredder. Do not wear loose

cbthing or jowcdry.

Operate chippor/shreddcrr only on a level surface.

Do not operate the chipper/shredder on a paved or gravel

surface.

●Before starting the chlpperlshredder, check that all

~screws, nuts, bolts and all other fasteners are properly

sekxrrcrd. Replaco all damaged or unreadable warning

and oporaling decals.

Check fuel Iovel bolore starting engine. Gasoline is highly

flammable; handle with care. Use only an approved

cOntalnor.

Do not fill fuel tank indoors, when engine Is running, or

until engine is allowed to cool. Do not smoke.

Reinstall fuel cap on tank and fuel container. Wipe the unit

clqan of any spilled fuel.

OPERATION

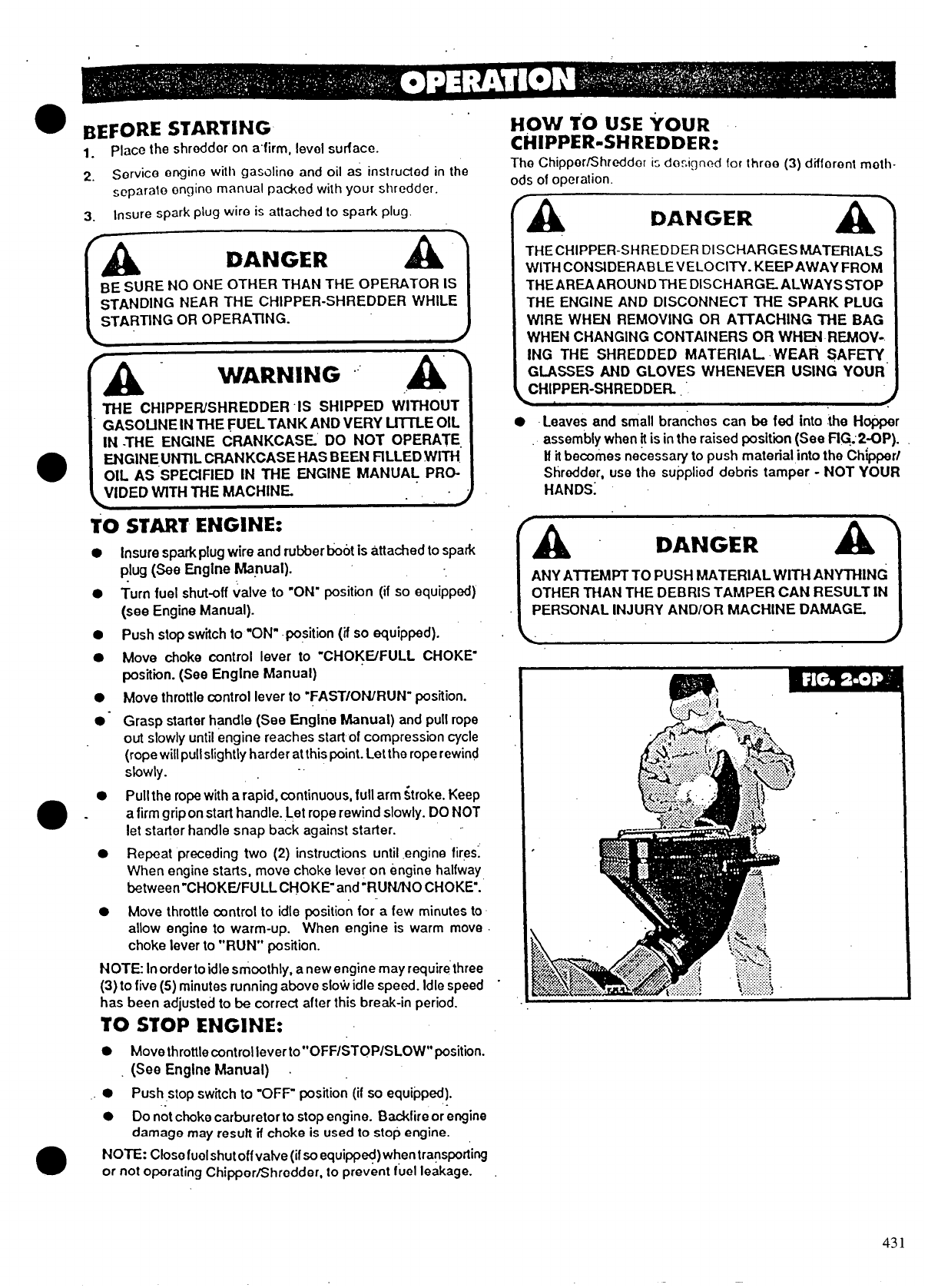

Beforo starling IIIC machine, operators shall make certain

that Iho cu[tinq charnbor is empty.

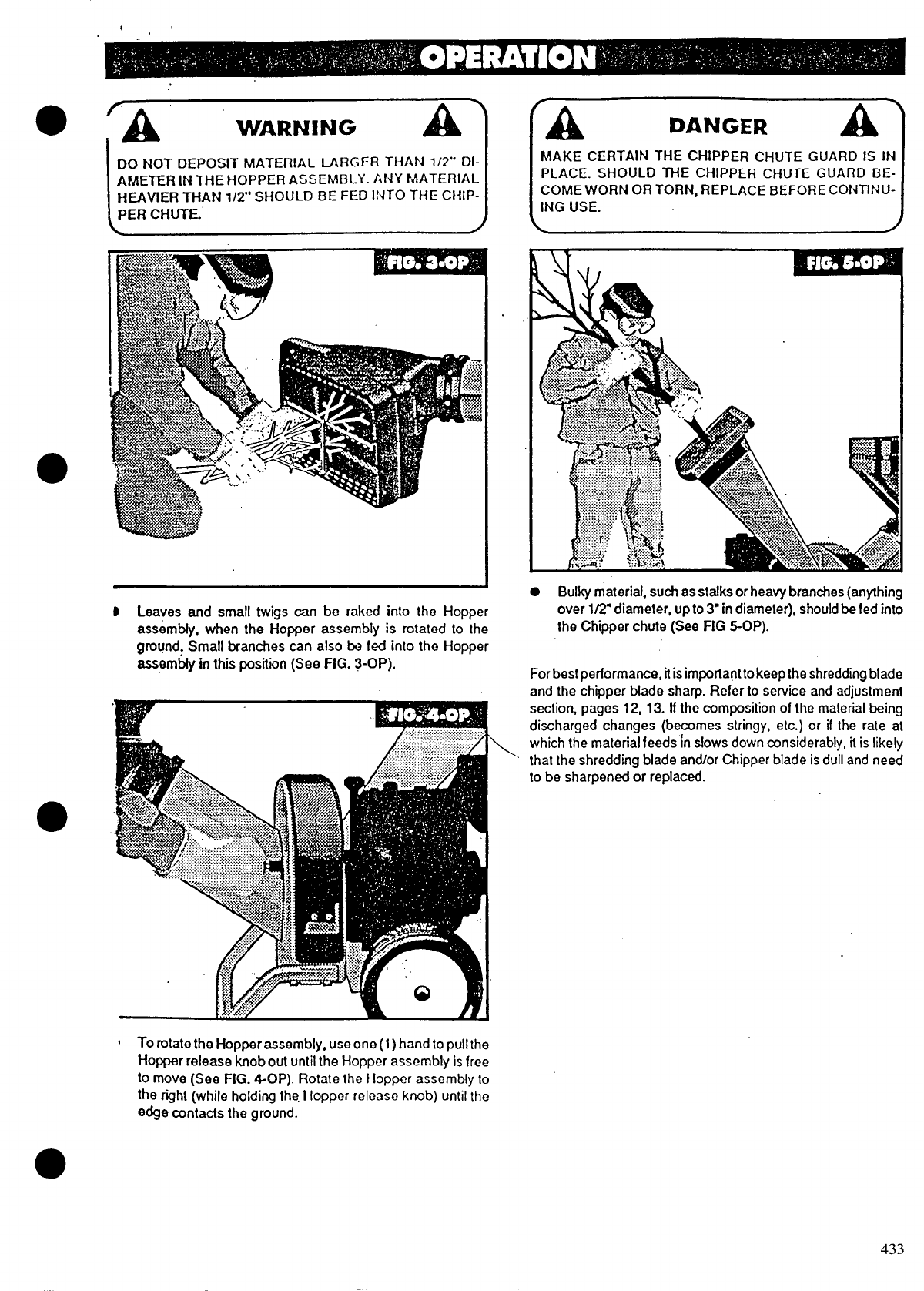

When Iectiiflg m[iteriai in!o this equipmenl, be extremely

carolul th;II piocor, of metal, rocks, bottles. cans or other

foroign objoc[z aro not incluctod. Personal injury or

damago to thomxhinc coufd result.

. . . .,

ff the cutting mechanism strikes any foreign object or n

your machine should start making an unusual noise or

vibration, immediately stop the engine, disconnect the

spark plug wire from the spark plug and move it away from

the spark plug. Aflow the machine to stop and take the

following steps:

InSped for damage.

Repface or repair Wy damaged parts.

Check for any hose parts and tghten to assure continued

safe operat.mn.

The engine must be kept clean of debris and other

accumulations.

Do not allow an accumulation of processed materiaf to

build up in the discharge area as this will prevent proper

discharge and can resutt in kick-bad from feed opening. -

Never pl~e your hands or any other part of your bbdy or

cfothing inside the feeding chamber,” discharge chute or

near any moving part while the engine is running.

Keep all guards and deflectors in place and in good

worfdng cxmditiirr to assure c%ntinued safe operatiin.

Always stand clear of the discharge area wheri operating

this machine.

Keep your face and body back from the feed opening to

avo”d accidental bunco bad of any material..

Do not over-reach. Keep proper balance and footing at all

times.

The engine governor, settings on your machine must not

be altered, changed, or tarripered with. The governor

controls the maximum safe ‘operating speeds and

protods the engine and all moving parts from damage

caused by over-speed. Authorized service personnel

slpuld perform these adjustments if aproblem exist.

Do not trans~rt machine while engine is running.

Do not operate engine it air cleaner or cover directly over

carburetor air intake is removed, except for adjustment.

Removaf of such parts cmufd create afire hazard. .

If chippkhreddor becomes cfogged the operator must

shut-off .e,ngirre, and discxrnnect spark plug before clearing

debris. . .

MA1tiNANCE AND STORAGE

When this equipment is stopped for servicing, inspectio~

storage or to change an accmssory, make sure the spark

plug wire is discmneded from the spark plug and moved

away from the spark plug. Tho machine should be

allowed to c@ down before making such inspection.

adjustments, service, elc. Maintain your machine with

caro and keep it clean Ior tho best and continuod safe

operat’km. Authorized sorwco shall be soughl if aproblem

oxisls.

Do not uso flammablo solutionc 10clwrII the air Iiller.

When not in use, your machmo chould t.m stored out of

tho roach of chikfron. Keep whoro ga$olino fumes will nof

roach an opon tlamo or spark. For kJIXJpurior.ts of storagoo

rofcr to Iho ‘Sloraao- section of lhi~ rnanu;d.

●~NING: This unit is equipped with an Inlomal ccrmbustion engine and should not be used on or near any unimproved lo~osl-covered.bnrsh-

red or ~rnss+nmrod fond unfess the ongkwr’sexhaust sys!om Is equippd wih aspark arrosfor meeting apphmbfo local or LIJIC laws (if any),

tpark amoster IS used, II should bo maintained in offoctiw working order by the opcrakx.

eSIaIc 01California tile above Is required by law (Section 4442 of the CafifornicrPUMCResources Code) Orhcr sratcwmay tmvc similar laws.

ml laws apply O(I Irxk, ral lands Aspmk wrcskr for the mulllcr is available throw)h your nearest engine mJhoIIzw_I:I:tvIcu deah:f

2421