McDonald's CORNELIUS AUTOMATED BEVERAGE SYSTEM User manual

OPERATOR’S MANUAL

This equipment chapter is to be inserted in

the Beverage Systems section of the

Equipment Manual.

AUTOMATED BEVERAGE SYSTEM

© 2004-2018 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Printed In

The United States of America

This manual is for the exclusive use of licensees and employees of McDonald’s Systems, Inc.

MANUFACTURED

EXCLUSIVELY FOR

McDONALD’S®

BY

CORNELIUS

PHONE (800) 238-3600

www.cornelius.com

FOR SERVICE CALL

COKE SMILE

1-800-241-COKE

TABLE OF CONTENTS

SAFETY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 1

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 4

PARTS IDENTIFICATION/FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 5

OPERATION MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 11

AUTOMATIC OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 12

SEMIAUTOMATIC OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 16

MANUAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 18

MAJOR SUBSYSTEMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 23

DAILY START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 39

CLOSING/SANITATION PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 41

DAILY CLEANING PROCEDURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 44

MONTHLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 45

QUARTERLY CLEANING/SANITATION PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 46

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 50

WIRING & PNEUMATIC DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 55

Part No. 569000181OPR

April 21, 2004

Revision: L

Revised: March 20, 2018

Automated Beverage System

© 2004-2018 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved. 1

SAFETY INSTRUCTIONS

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

Safety Overview

• Read and follow ALL SAFETY INSTRUCTIONS in this manual and any warning/caution labels on the unit

(decals, labels or laminated cards).

• Read and understand ALL applicable OSHA (Occupational Safety and Health Administration) safety

regulations before operating this unit.

Recognition

DIFFERENT TYPES OF ALERTS

!

DANGER:

Indicates an immediate hazardous situation which if not avoided WILL result in serious injury, death or

equipment damage.

!

WARNING:

Indicates a potentially hazardous situation which, if not avoided, COULD result in serious injury, death, or

equipment damage.

CAUTION:

!

Indicates a potentially hazardous situation which, if not avoided, MAY result in minor or moderate injury

or equipment damage.

SAFETY TIPS

• Carefully read and follow all safety messages in this manual and safety signs on the unit.

• Keep safety signs in good condition and replace missing or damaged items.

• Learn how to operate the unit and how to use the controls properly.

• Do not let anyone operate the unit without proper training. This appliance is not intended for use by very young

children or infirm persons without supervision. Young children should be supervised to ensure that they do not

play with the appliance.

• Keep your unit in proper working condition and do not allow unauthorized modifications to the unit.

Recognize Safety Alerts

This is the safety alert symbol. When you see it in this manual or on the unit,

be alert to the potential of personal injury or damage to the unit.

!

Automated Beverage System

© 2004-2018 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

2

QUALIFIED SERVICE PERSONNEL

!

WARNING:

Only trained and certified electrical, plumbing and refrigeration technicians should service this unit. ALL

WIRING AND PLUMBING MUST CONFORM TO NATIONAL AND LOCAL CODES. FAILURE TO

COMPLY COULD RESULT IN SERIOUS INJURY, DEATH OR EQUIPMENT DAMAGE.

SAFETY PRECAUTIONS

This unit has been specifically designed to provide protection against personal injury. To ensure

continued protection observe the following:

!

WARNING:

Disconnect power to the unit before servicing following all lock out/tag out procedures established by the

user. Verify all of the power is off to the unit before any work is performed.

Failure to disconnect the power could result in serious injury, death or equipment damage.

CAUTION:

!

Always be sure to keep area around the unit clean and free of clutter. Failure to keep this area clean may

result in injury or equipment damage.

SHIPPING AND STORAGE

CAUTION:

!

Before shipping, storing, or relocating the unit, the unit must be sanitized and all sanitizing solution must

be drained from the system. A freezing ambient environment will cause residual sanitizing solution or

water remaining inside the unit to freeze resulting in damage to internal components.

CO2(CARBON DIOXIDE) WARNING

!

DANGER:

CO2displaces oxygen. Strict attention MUST be observed in the prevention of CO2gas leaks in the

entire CO2and soft drink system. If a CO2gas leak is suspected, particularly in a small area,

IMMEDIATELY ventilate the contaminated area before attempting to repair the leak. Personnel exposed

to high concentrations of CO2gas experience tremors which are followed rapidly by loss of

consciousness and DEATH.

!

WARNING:

It is the responsibility of the installer to ensure that the water supply to the dispensing equipment is

provided with protection back flow by an air gap as defined in ANSI A 112.1.2-1979; or an approved

vacuum breaker or other such method as proved effective by test and must comply with all federal, state

and local codes.

Failure to comply could result in serious injury, death or damage to the equipment.

Water pipe connections and fixtures directly connected to a potable water supply shall be sized, installed

and maintained according to Federal, State and Local laws.

!

WARNING:

This unit is not designed for a wash down environment and must NOT be placed in an area where a

water jet could be used.

Automated Beverage System

© 2004-2018 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved. 3

Failure to comply could result in serious injury, death or damage to the equipment.

!

WARNING:

Water and CO2to the system must be turned off and the system depressurized prior to performing this

service.

Failure to comply could result in serious injury, death or damage to the

equipment.

!

WARNING:

This unit must be grounded to avoid possible electrical shock to the operator. The unit power cord is

equipped with a three pronged plug. If a three pronged (grounded) outlet is not available use an

appropriate method to ground the unit.

Failure to comply could result in serious injury, death or damage to the equipment.

Automated Beverage System

© 2004-2018 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

4

INTRODUCTION

The Automated Beverage System (A.B.S.) is

an automated cold beverage dispenser for

drive-thru applications. The ABS was

designed for drive-thru area installation or

other restricted area that is not accessible to

unauthorized personal. When a beverage is

ordered from the P.O.S. register, the A.B.S.

automatically drops a cup, fills it with ice and

dispenses the correct amount and type of any

syrup-based beverage. The finished drink is

then moved by the conveyor to the pick-up

station and the drink description is displayed

on the panel.

Operation of the ABS is restricted to employ-

ees and service personal that have been

trained and certified in the proper operation,

service and maintenance of the equipment.

The ABS has three modes of operation:

• Automatic Mode

In automatic mode, the customer places an

order at the drive-thru and the A.B.S. auto-

matically produces the order. If extra or no ice

drinks are ordered, they are entered from the

P.O.S. as a “grill order” and the A.B.S.auto-

matically produces the drink as ordered.

• Semiautomatic Mode

In automatic mode, operator presses desired

cup size button, desired flavor button and

ENTER and drink is dispensed. If extra ice or

no ice is required, EXTRA ICE or NO ICE

button is pressed after flavor button has been

pressed, before ENTER. Drink is dispensed.

• Manual Mode

Remove the conveyor. Enter the manual mode

by pressing the Manual/Auto button. (Don’t

pull cups from A.B.S. Turret as damage may

occur to cup tubes.) Locate a sleeve of cups

and remove a cup. Hold the cup under ice

chute, press EXTRA ICE. Ice is dispensed.

Hold cup under nozzle, press and hold desired

flavor button. Drink is dispensed. Reinstall

conveyor and return A.B.S. unit to normal

operation.

SAFETY

Always disconnect CO2or air pressure to unit

before cleaning or servicing grabber arm or

ice chute. Disconnect switch for ice gate is

located on control box behind cup lid holder

panel.

Insure that unit is in manual mode before

removing or replacing conveyor assembly to

avoid pinching fingers in the drain area.

Dispenser is very top heavy. To prevent seri-

ous injury, exercise caution when moving or

setting dispenser in place.

CO2used in the system is under 60 PSI min.

pressure. (ABS has a regulator to control up to

200PSI incoming). Caution should be used

when servicing the unit. Undetected CO2

leaks may cause harm or death due to aphyxi-

ation. Installation and service personal must

carefully inspect all CO2tubing, fittings and

components for any damage or leaks. Also

check and clean all fittings before reusing.

Make sure tank is properly secured to avoid

tipping.

Noise level can exceed 65 dBA in short time

intervals for single unit activities. Warning

devices are 88dBA at 24” from unit. Measure-

ment for noise shall be made 39” from any

machine surface.

Unit is equipped with independent manual

leveling legs. Total incline not to exceed 5

degrees in any direction.

Functions without damage from 32°-105°F

with 100% rh, incoming water & syrup of

32°-105°F. No visible condensation on out-

side or dripping inside dispenser when oper-

ated at 75°F, 45% rh or 90°F, 65% rh.

Automated Beverage System

© 2004-2018 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

Illustrated Parts List

5

Automated Beverage System —

Ref CCUSA MFG.

Number Number Number Description

PRINTED ON RECYCLED PAPER

10% Post-Consumer Content

40% Pre-Consumer Content

1 .................... ................ 620052935 .....Ventilation Grill

2 .................... ................ 620516680 .....Access Hole Cover

3 .................... ................ 560000291 .....Air Filter

4 .................... ................ 560000289 .....Front Panel (Built before Serial No. 56A0019AB102)

...................... ................ 560002774 .....Front Panel (Serial No. 56A0019AB102 and after)

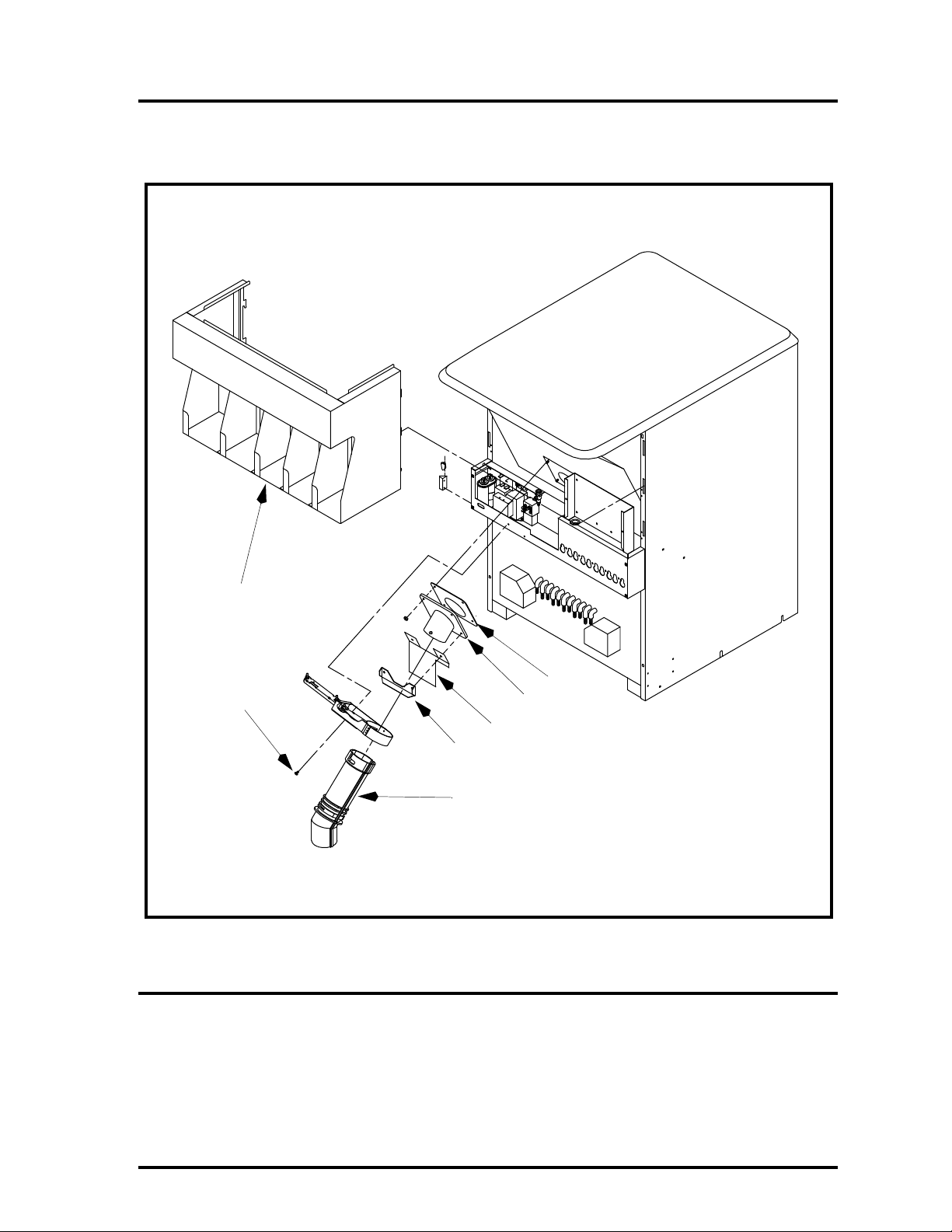

Assembled Unit Diagram

A.B.S. Unit Access

12

3

4

TURRET

FLAVOR DISPLAY

CUP GRABBER

CONTROL PANEL

ON/OFF SWITCH

OPTIONAL PRECHILLER

Automated Beverage System

© 2004-2018 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

Illustrated Parts List

6

Automated Beverage System —

Ref CCUSA MFG.

Number Number Number Description

1 27921 ...... 560000320Conveyor Cover

2 .............. 27922...................560000325 ..............Conveyor Assembly

3 .............. .............................560000315 ..............Cup Rest

4 .............. .............................560000306 ..............Drip Tray Assembly

Conveyor/Cup Rest Assembly Diagram

1 ................ 27921...........560000320 ...... Conveyor Cover

2 ................ 27922...........569000295 ...... Conveyor Assembly

3 ................ ..................... 560000315 ...... Cup Rest

4 ................ ..................... 560000306 ...... Drip Tray Assembly

5 ................ 20669...........560002714 ...... Water Deflector

Conveyor Assembly

1

2

3

4

POSITION “A” SENSOR

CUP POSTIONING BRACKET

CUP HOLDER

THUMB SCREWS

5

Automated Beverage System

© 2004-2018 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

Illustrated Parts List

7

Automated Beverage System —

Ref CCUSA MFG.

Number Number Number Description

Ice Chute Assembly Components Diagram

1 ................ ...................560000392 ..... Ice Chute Gasket

2 ................ ...................560000344 ..... Ice Chute Mounting Plate

3 ................ 27926.........560000346 ..... Ice Chute

4 ................ ...................560002728 ..... Ice Chute Stiffener

5 ................ ...................560000398 ..... Machine Screw, Phillips Truss Head, No. 8 x .5”

6 ................ ...................560001548 ..... Ice Chute Shield

7 ................ ...................620014801 ..... Lid Holder Assembly

8 ................ 28076.........560001589 ..... Ice Chute Cleaning Brush (Not Shown)

Ice Chute Assembly

1

2

3

6

5

4

7

Automated Beverage System

© 2004-2018 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

Illustrated Parts List

8

Automated Beverage System —

Ref CCUSA MFG.

Number Number Number Description

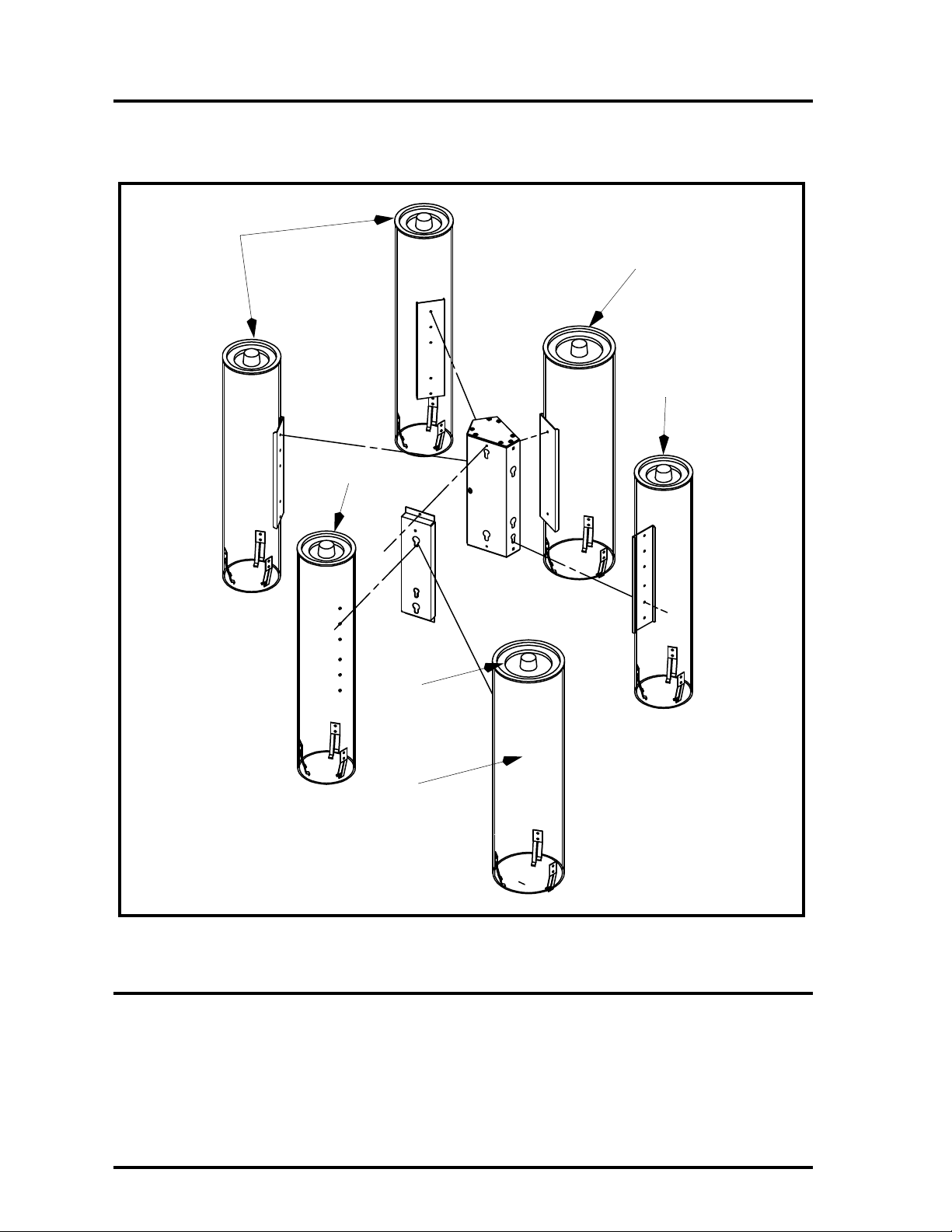

Cup Tube Components Diagram

1 ..............27916 ..........560000207 .......5” Cup Tube Cover (30/32 - 42 oz.)

2 ..............27915 ..........560000206 .......4” Cup Tube Cover (12 - 21 oz.)

3 ..............28377 ..........569000199 .......42 Oz. Cup Tube Kit

N/R .........28373 ..........569000172 .......12 Oz. Cup Tube Assembly Kit (Australian “Small” size)

N/R .........28374 ..........569000173 .......16 Oz. Cup Tube Assembly Kit (Australian “Medium” size, station 3)

N/R .........28375 ..........569000174 .......21 Oz. Cup Tube Assembly Kit (Australian “Large” size, station 1)

N/R ......... ....................569000175 .......30/32 Oz. Kit Cup Tube 32 Oz. ABS

N/R ......... ....................569000159 .......21 Oz. Cup Tube Assembly Kit (Australian “Large” size, station 2)

N/R ......... ....................569030035 .......Medium Cup Tube Assembly Kit Station 5, (Australian ABS only)

Cup Tube Assembly

1

2

3

2

2

1

Automated Beverage System

© 2004-2018 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

Illustrated Parts List

9

Automated Beverage System —

Ref CCUSA MFG.

Number Number Number Description

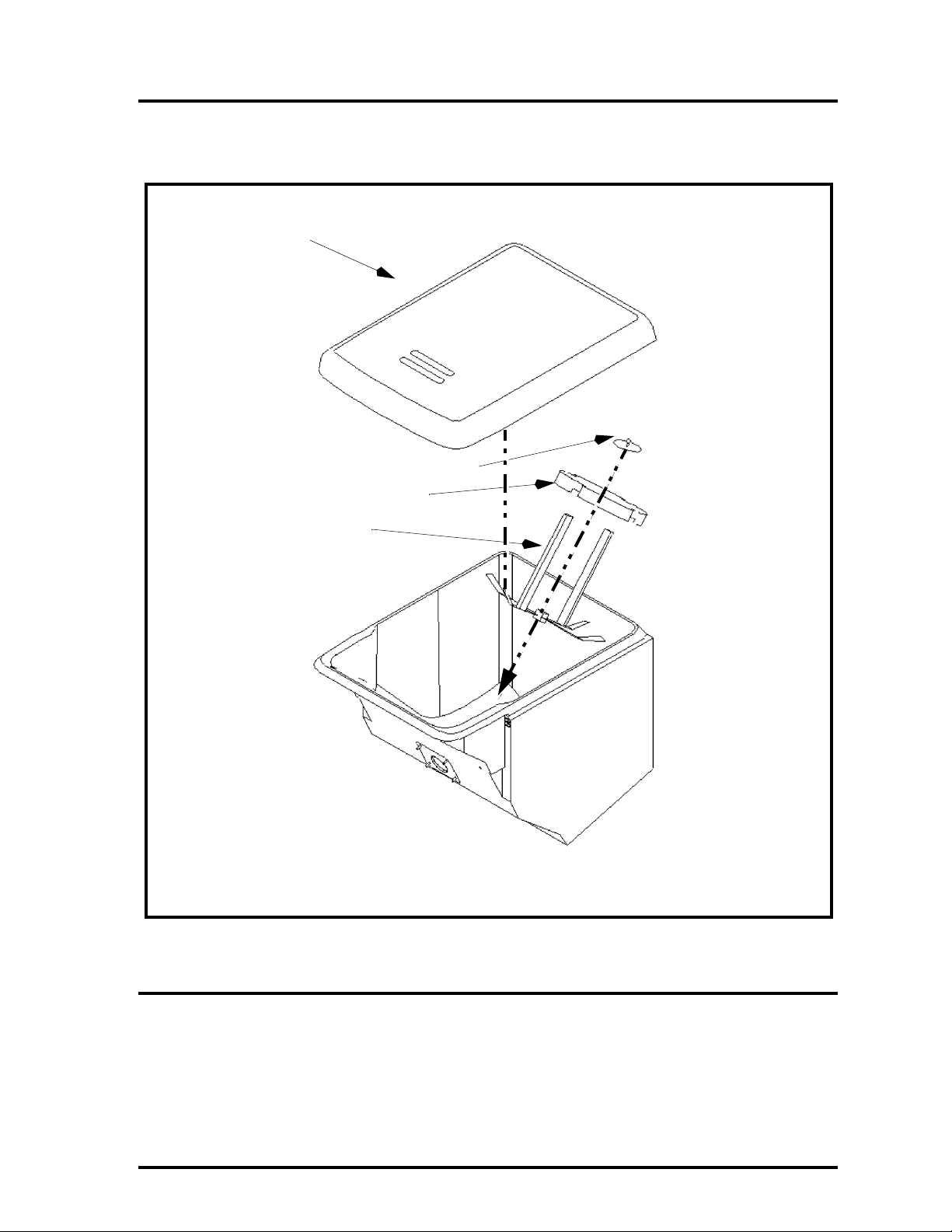

Ice Bin Components Diagram

1 ............... ............................15346 ...................... Agitator Assembly

2 ............... ............................52887 ...................... Lid

3 ............... ............................53227 ...................... Disk

4 ............... ............................15087 ...................... Agitator Retainer

1 .............. 15346................................ Agitator Assembly

2 .............. 52887................................ Lid

3 .............. 53227................................ Disk

4 .............. 15087................................ Agitator Retainer

Agitator Assembly

1

3

2

4

Automated Beverage System

© 2004-2018 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

Illustrated Parts List

10

Automated Beverage System —

Ref CCUSA MFG.

Number Number Number Description

Nozzle Assembly Components Diagram

.................. 161509 ................ Complete Assembly

1................27940 560001545 .......... Nozzle

2................27939 560001544 .......... Diffuser

3................ 110677000 .......... O-Ring

6................ 325216000 ..........Nozzle Brush (Not Shown)

Nozzle Assembly

1

3

4

5

1

22A

2B

DIFFUSER BODY

DIFFUSER RING

Automated Beverage System

© 2004-2018 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved. 11

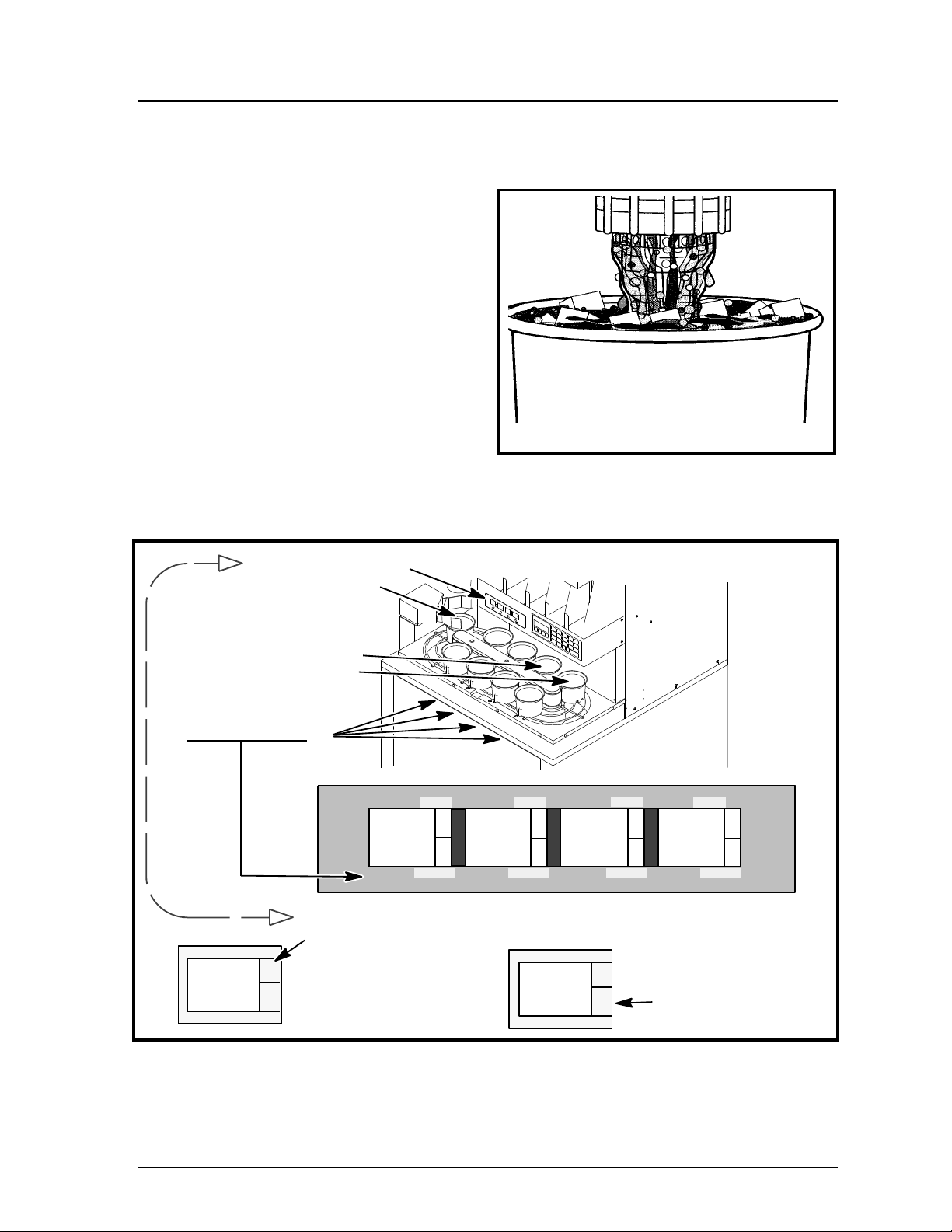

COKE *

SPECIAL

EXTRA ICE

ABCD

Cup Extraction Position

Ice Fill Position

Beverage Fill Position

BCD

A

Conveyor Positions

*Drink Position Display

*Drink Position Display - Showing Drink Locations in Conveyor

AN * IS DISPLAYED WHEN A

DRINK IS DISPENSED FROM THE

A.B.S. PANEL INSTEAD OF THE

POS SYSTEM.

A # IS DISPLAYED

FOR ANY DRINK DISPENSED

WITH EXTRA ICE.

COKE

SPECIAL

EXTRA ICE

#

SPECIALSPECIAL SPECIAL

SPECIAL

EXTRA ICE EXTRA ICE

EXTRA ICE

EXTRA ICE

Fully Automatic Operation

Operational Modes

The A.B.S. has three modes of operation:

• Automatic (Normal Operation)

• Semi-Automatic (while in Auto)

•Manual

Location Diagram

Automated Beverage System

© 2004-2018 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

12

Order Entered On P.O.S.

Operation of the ABS is restricted to employ-

ees and service personal that have been

trained and certified in the proper operation,

service and maintenance of the equipment.

With the unit in automatic mode, the cus-

tomer places an order at the Drive-Thru.

Special Ice Drinks

Extra and no ice drinks are entered from the

P.O.S. as a “grill order.” The A.B.S. will auto-

matically produce the drink to the special

order.

P.O.S. Signal To Manager’s Computer

The order is transmitted from the P.O.S. to the

store computer and from there to the A.B.S.

unit.

Automatic Operation

Automated Beverage System

© 2004-2018 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved. 13

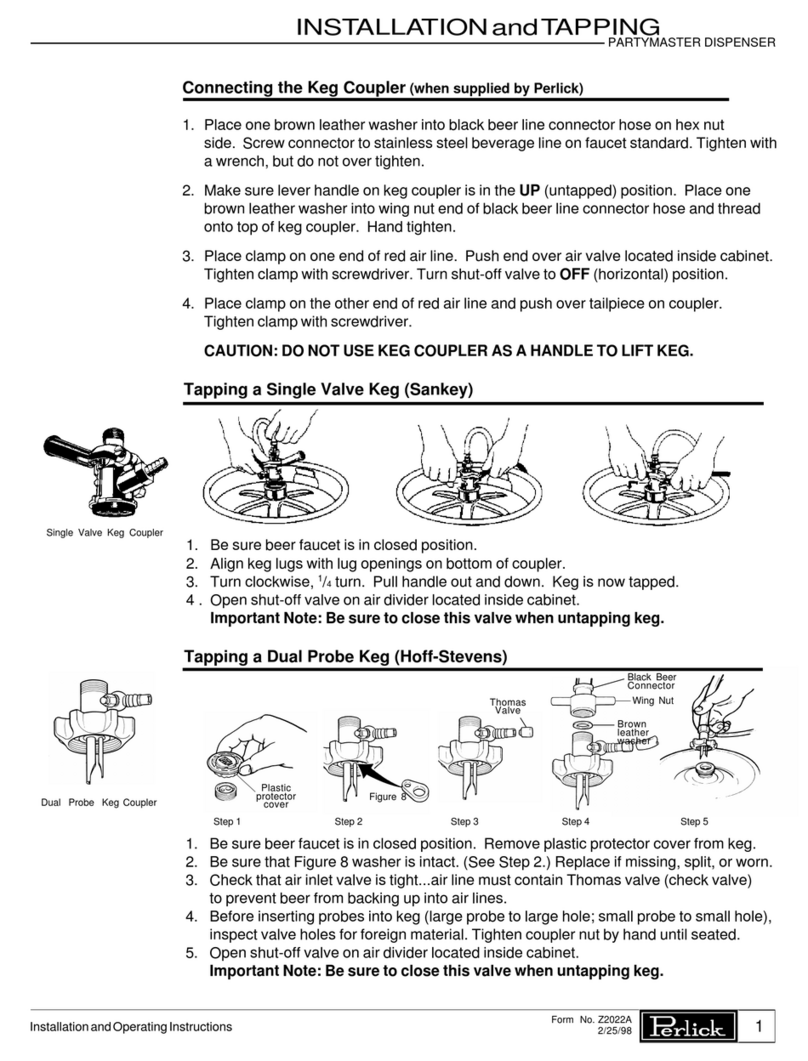

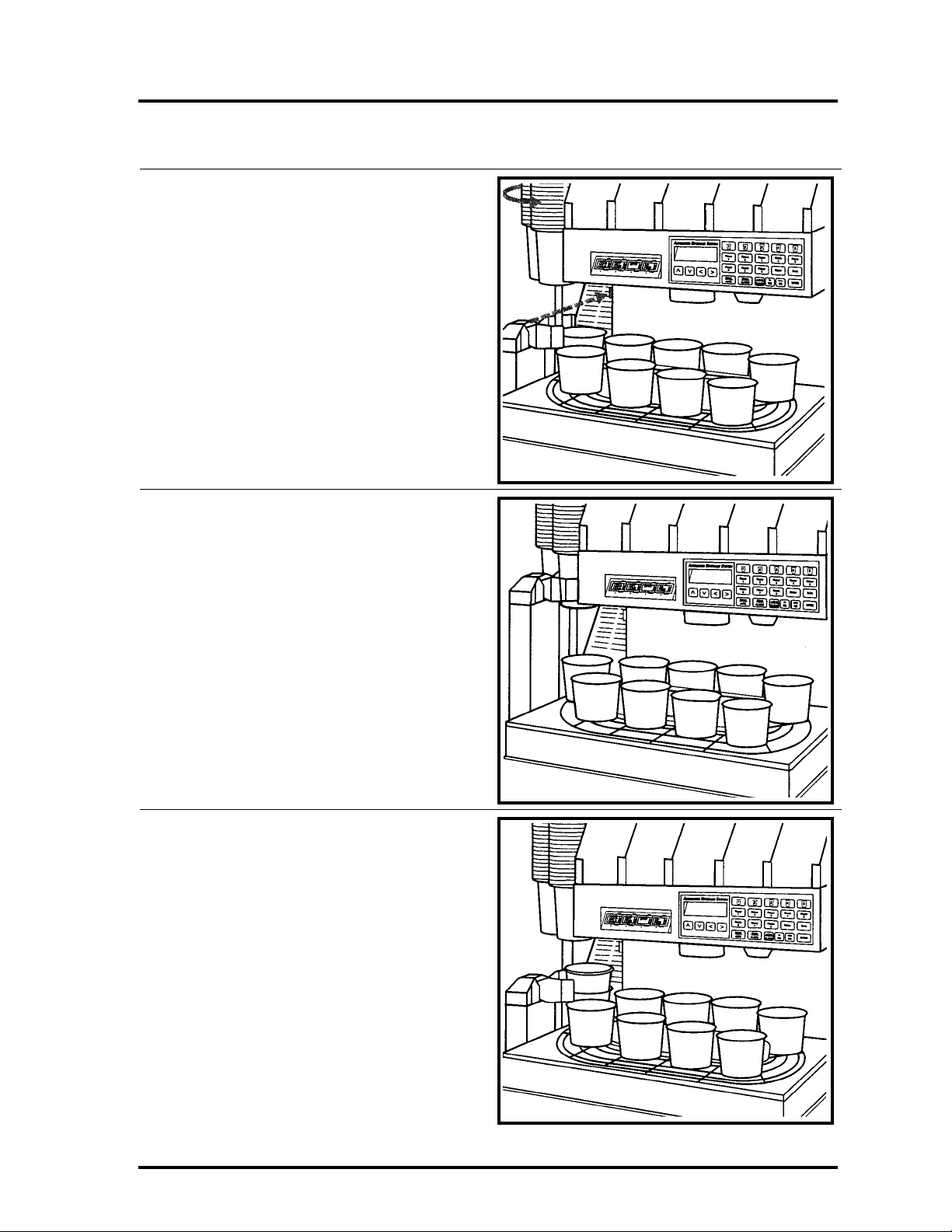

Cup Turret Rotates

The cup turret rotates to move the proper size

cut to the extract position.

Cup Grabber Rises & Closes

The cup grabber is lifted by a pneumatic cyl-

inder up to the cup. The travel is sensed by

the full travel sensor. If full height is reached,

a pneumatic cylinder closes the grabber arms

against the cup. A sensor detects if cups are

available.

Grabber Lowers & Opens

The cup grabber lowers, pulling the cup from

the cup tube and then the arms open dropping

the cup into the conveyor.

If the grabber should slide off a cup, it would

be detected by the cup sensor.

Automatic Operation

Automated Beverage System

© 2004-2018 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

14

Conveyor Operates

Sensors check for a cup in position “A.” If the

sensor is clear, the conveyor rotates clock-

wise to move the cup to the ice chute.

This is based on only one drink being

ordered. If a second drink had been ordered,

the conveyor would have moved only one

position and the second cup would have been

extracted and dropped into the conveyor. The

two cups would then be moved clockwise

until the first cup reaches the ice fill port.

Ice Portion Is Dispensed

The ice gate is opened by a pneumatic cylin-

der for the time needed to dispense the

selected ice portion. Correct operation is

insured by the ice gate full travel sensor.

The agitator continues to operate for the set

refill time to refill the ice chute.

Automatic Operation

Automated Beverage System

© 2004-2018 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved. 15

Cup To Dispensing Nozzle

Sensors check for a cup in position A. If the

sensor is clear, the conveyor moves the cup to

the beverage fill point. The valve opens to

dispense the desired syrup and water in the

desired portions into the cup.

Beverage Dispensed

The computer sends the drink portion of the

order to the A.B.S. where the information is

interpreted and the drink is dispensed.

If the drink requires a top-off, the initial por-

tion will be dispensed. After a delay, the bal-

ance of the drink will be dispensed.

Automatic Operation

Automated Beverage System

© 2004-2018 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

16

Cup Is Moved To Cup Serve Point

Sensors check for a cup in position “A.” If the

sensor is clear, the conveyor moves the cup to

cup serve position “D”.

The display will indicate the flavor of the

beverage at cup serve position “D”.

Crew Member Serves Drink

A crew member caps the drink while still on

the conveyor and serves it with the remainder

of the order.

Semiautomatic Operation (Unit in Automatic)

Automated Beverage System

© 2004-2018 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved. 17

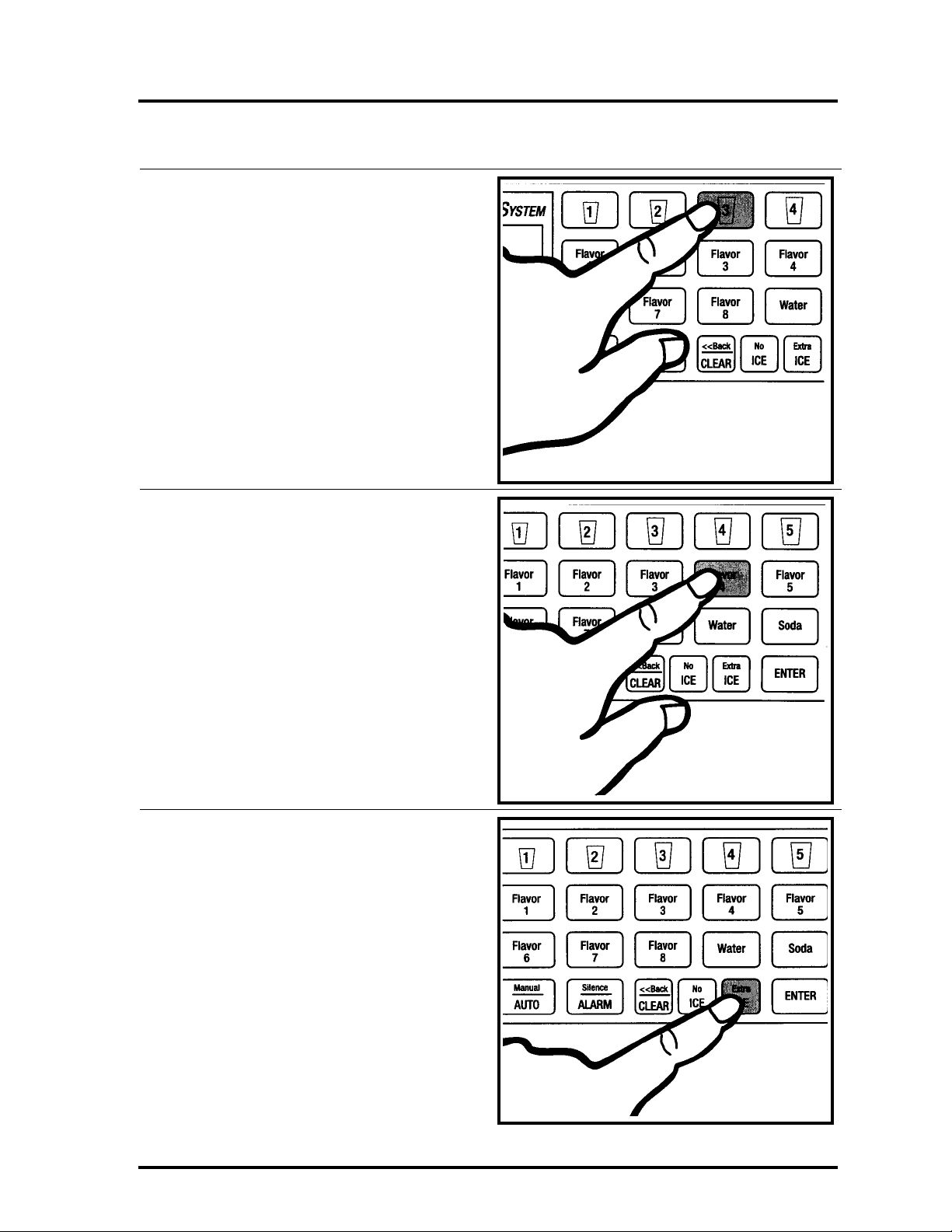

Press Cup Size

Operation of the ABS is restricted to employ-

ees and service personal that have been

trained and certified in the proper operation,

service and maintenance of the equipment.

While in automatic mode, to dispense a drink

in the semi-automatically, press the desired

cup size button.

Press Flavor

Press the desired flavor button.

Press Special Ice Requirement If

Requested

If extra ice is desired, press the EXTRA ICE

button. If no ice is required, press the NO ICE

button.

If normal ice is desired, no button is pressed.

Semiautomatic Operation (Unit in Automatic)

Automated Beverage System

© 2004-2018 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

18

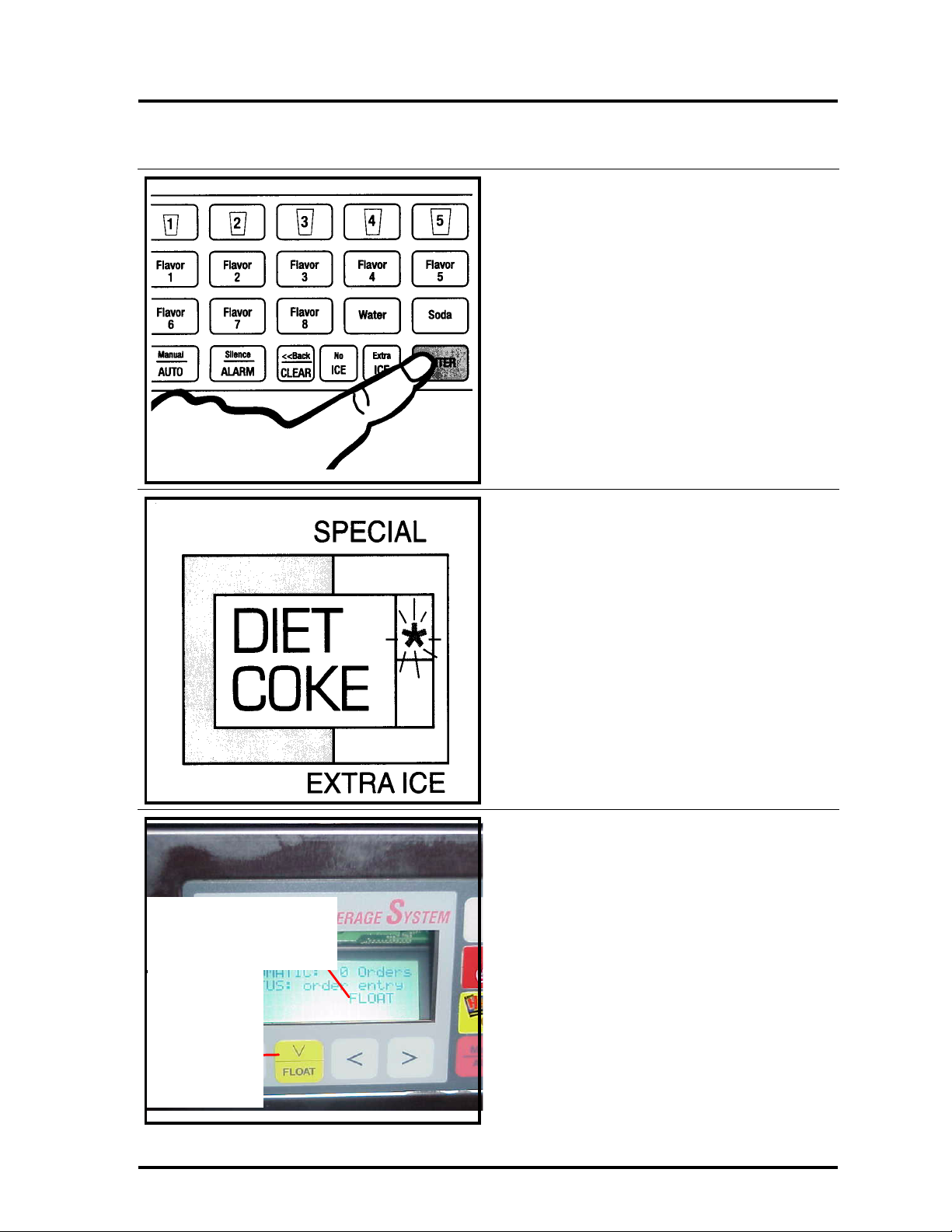

When Correct, Press Enter

Sequence of pressing the cup size, flavor, and

special ice buttons is not important. At any

time, pressing any button changes the selec-

tion of the drink to be dispensed. When the

correct order is displayed, press ENTER and

the drink is dispensed.

Any drink entered in this manner displays an

illuminated asterisk in the SPECIAL section

of the Drink Position Display identifying the

semiautomatic drink selected at the A.B.S.

panel.

ABS Float Dispensing

ABS Float Dispensing allows for the ABS to

dispense drinks, without ice, that are only a

pre-set portion full. Ice cream can then be

added after the dispense, to make it into a

“FLOAT” drink.

Ordering a Float Drink

1. Place the unit in AUTOMATIC MODE

2. Select the CUP SIZE

3. Select the FLAVOR

4. Press the DOWN ARROW/FLOAT KEY

5. Press ENTER

The word “FLOAT” will appear

when the float option is applied

to the drink order.

This button op

erates as the

DOWN arrow key

in the manual

mode, and as the

“FLOAT” key

while the unit is

in automatic.

The word “FLOAT” appears

when the float option is

applied to the drink order.

This button oper-

ates as the

DOWN arrow

key in the manual

mode, and as the

“FLOAT” key

while the unit is

in automatic.

Manual Operation

Table of contents

Other McDonald's Beverage Dispenser manuals