2

Ambient Air Temperature

Locate the dryer indoors where the ambient air temperature will

be between 39°F (4°C) and 122°F (50°C). Intermittent operation

at ambient temperatures up to 122°F (50°C) will not damage the

dryer but may result in a higher dew point or dryer shutdown

due to high refrigerant discharge pressure (see Field Service

Guide). Call your local distributor if prolonged operation at

ambient temperatures above 122°F (50°C) or below 39°F (4°C)

is unavoidable.

Do not operate air-cooled dryers at ambient air temperatures

below 39°F (4°C). Such operation may result in low suction pres-

sure, causing freeze-up.

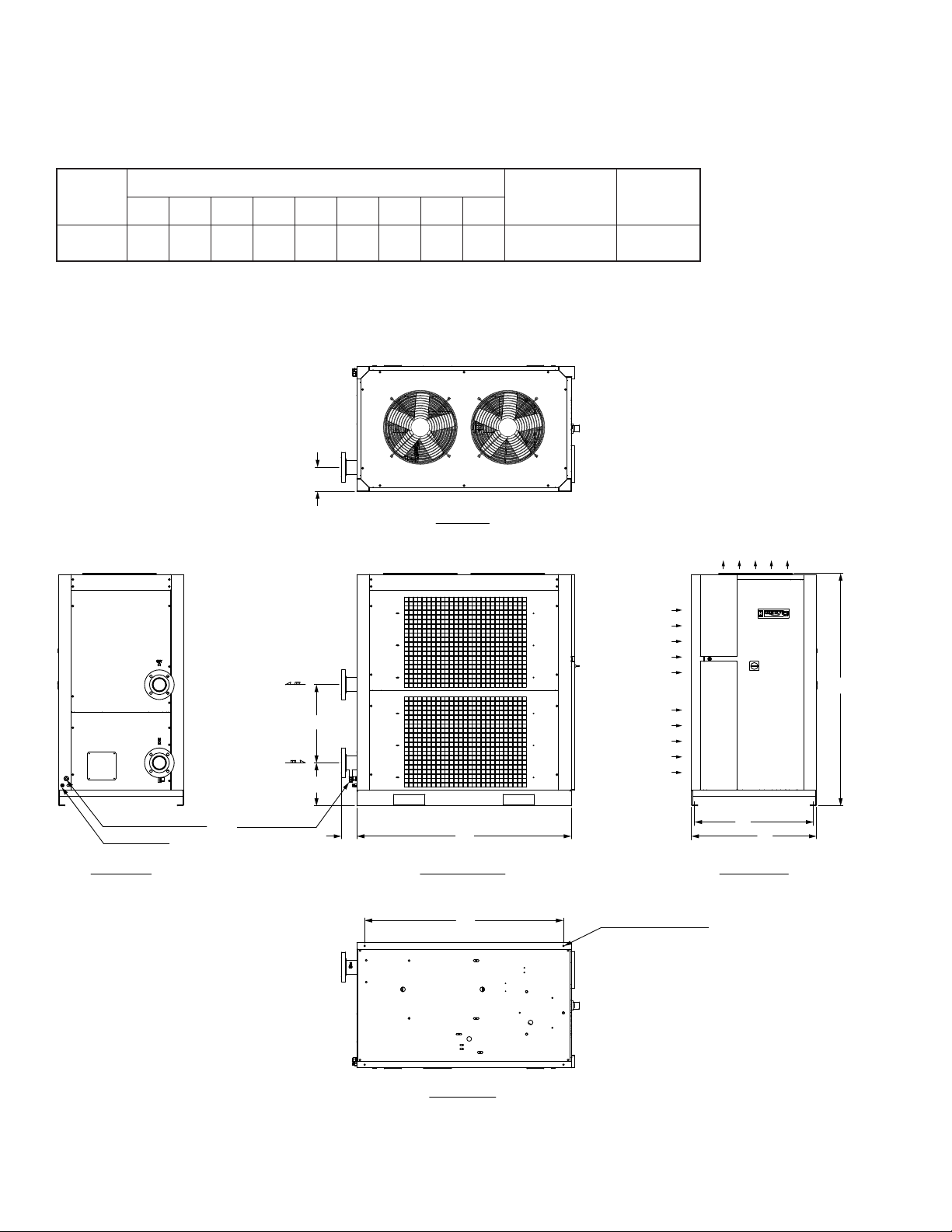

Location and Clearance

Mount the dryer on a level base and bolt down if the base vi-

brates. If the dryer is air cooled, install it in a clean, well-ventilated

area to reduce fouling of the condenser coils with dirt and dust.

Allow 48 inches (1220 mm) clearance on the sides and the front

of the dryer for cooling airflow and service access.

System Arrangement

Liquid water adversely affects dryer performance. To prevent

“slugging” the dryer with liquid water, locate the dryer down-

stream of an aftercooler and a mechanical separator. Install

drain valves to discharge condensate that collects in these areas.

If the airflow is relatively constant and will not cause short term

overloading of the dryer, it is recommended that the dryer be

located downstream of the receiver tank. If the nature of the

application is such that the air demand regularly exceeds the

dryer flow rating, it is recommended that the dryer be located

upstream of the receiver.

For safety and convenience, install inlet and outlet shutoff

valves and depressurization valves at the locations indicated.

These valves allow the dryer to be isolated and depressurized

for servicing. Bypass piping may be installed around the dryer

for uninterrupted airflow when the dryer is serviced. If the com-

pressed air operation cannot tolerate wet air for short periods,

install a second dryer in the bypass line.

Compressed air systems commonly require filters to remove

compressor oils, particulates, condensed liquids and other

contaminants. When an oil-removal filter is used, install the

filter downstream of the dryer. At this location, the life of the

replaceable filter element is prolonged since the dryer removes

some of the entrained oil and drained through the separator.

Piping and Connections

The user must furnish piping unless otherwise specified. Con-

nections and fittings must be rated for the maximum operating

pressure given on the dryer data plate and must be in accor-

dance with applicable codes. Support all piping; do not allow

the weight of any piping to stress the dryer or filters. Inlet and

outlet shutoff valves and bypass valves are recommended. Pip-

ing should be at least the size of the inlet and outlet connections

to minimize pressure drop in the air system. See Specification

Table for dryer inlet and outlet connections.

Drains

Condensate must be drained from the dryer to prevent an influx

into outlet air. The FLEX dryers are equipped with an automatic

no loss drain valve and internal drain hoses up to the drain con-

nections on the dryer cabinets.

The user must install a discharge line from the drain connection

and run it to a waste disposal collection system that meets ap-

plicable regulations. Pipe or copper tubing 1/2 inch or larger is

recommended for condensate discharge lines. Install the drain

lines so that condensate can be seen as it drains.

NOTE: Discharge is at system pressure. Drain line should be

anchored.

NOTE: Condensate may contain oil. Comply with applicable laws

concerning proper disposal.

Drain Valve Operation

A. Verify that isolation valves are open. If the drain fails to

discharge after the valve is energized, the electronic control

circuit will repeatedly energize the valve in an attempt to

clear the discharge port. If, after 60 seconds, the drain still

fails to discharge, the control circuit then switches to the

alarm mode. In this mode the valve is de-energized and the

red alarm light is activated on the drain. The valve is then

automatically energized every 4 minutes for 5 seconds.

Check the drain operation. Push drain (push-to-test) button

on the drain or the Electronic Controller (if equipped) to

energize drain. A flow of condensate and/or air should be

present at the drain outlet. The alarm mode automatically

clears after the drain returns to normal operation.

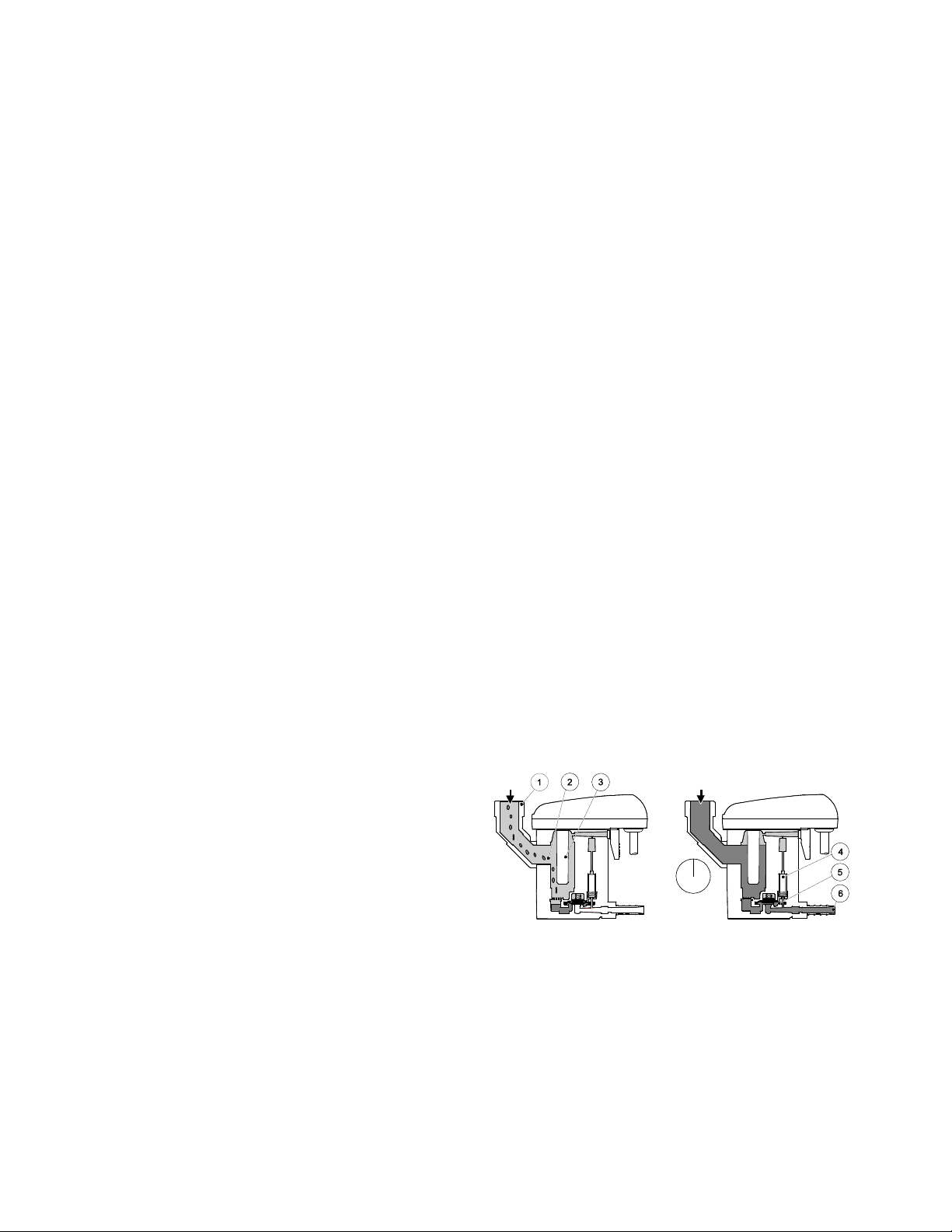

B. The condensate flows through the feed line (1) into the

condensate drain and accumulates in the housing (2). A

capacitive sensor (3) continuously registers the liquid level.

As soon as the container is filled, a fixed waiting period

begins during which more condensate accumulates. After

the waiting time has expired the pilot valve (4) is then ac-

tivated and the diaphragm (5) opens the outlet line (6) for

discharging the condensate.

When the condensate drain has been emptied, the outlet

line is closed again quickly and tightly without wasting

compressed air.

Figure 1.

Schematic diagram of the no loss drain valve

MCGUIRE AIR COMPRESSORS INC

MCGUIRE AIR COMPRESSORS INC