MAINTENANCE

Crusader

MC-8

[.,

0

,_1_-7

___

DAIE_M~ay~,

_19_74

__

] ·

MANUAL

SPECIFICATIONS

AXLE

CENTER

Type

.........

_.

..............................................................

I

Beam

Allowable

Twist

(Variation

between

ends)

.......................................

1/2°

STEERING

KNUCKLES

Spindle

diameter:

Inner

Bearing

....................................

2.5623-2.5613

in.

Outer

Bearing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1248-2.1243

in.

Up-and-down

Movement,

Maximum

...........................................

015

m.

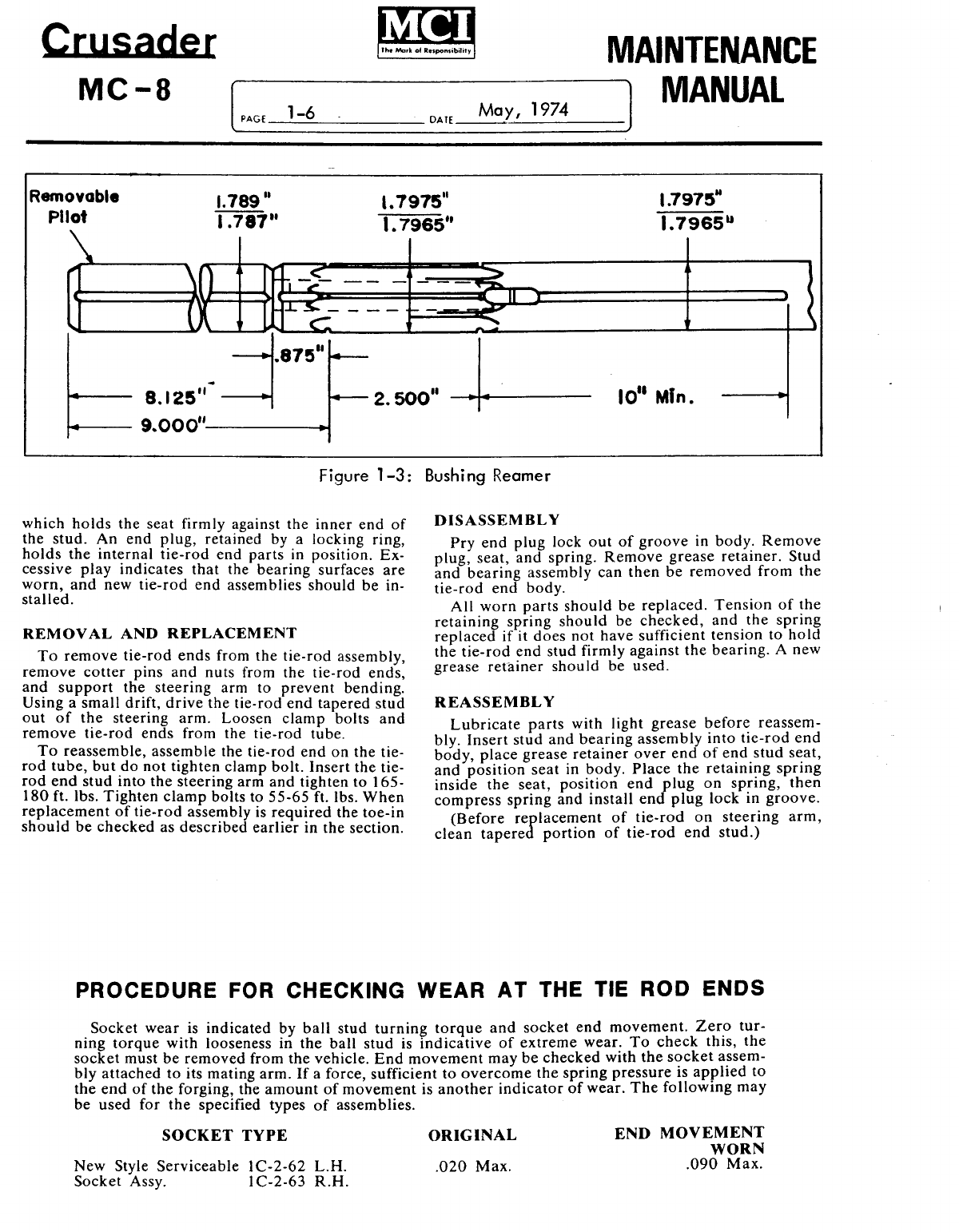

Bushing

bore,

diameter.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.919-1.921 m.

STEERING

KNUCKLE

BUSHINGS

Material.

:

...................................................................

Bronze

Inside

-

Line

ream

...............................................

1.7935-1.7945

in.

Line

burnish

..................................................

1.7965-1.7975

in.

KING

PIN

Type

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tapered

Diameter

-

Large

End

..............................................

1.794-1.793

in.

Small

End

..................................................

1.3095-1.3085

in.

LOCATION

Tie-Rod

End

Nut

Tie-Rod

Clamp

Bolt

Steering

Arm

Ball

Nut

Steering

Arm

Nut

King Pin

Nut

TORQUE

SPECIFICATIONS

DIAMETER

7

/8"

5/8,

7

/8"

1-1/8"

1-1/8"

LB./FT.

165-180

55-65

165-180

350-390

350-390