Date Page

1-2

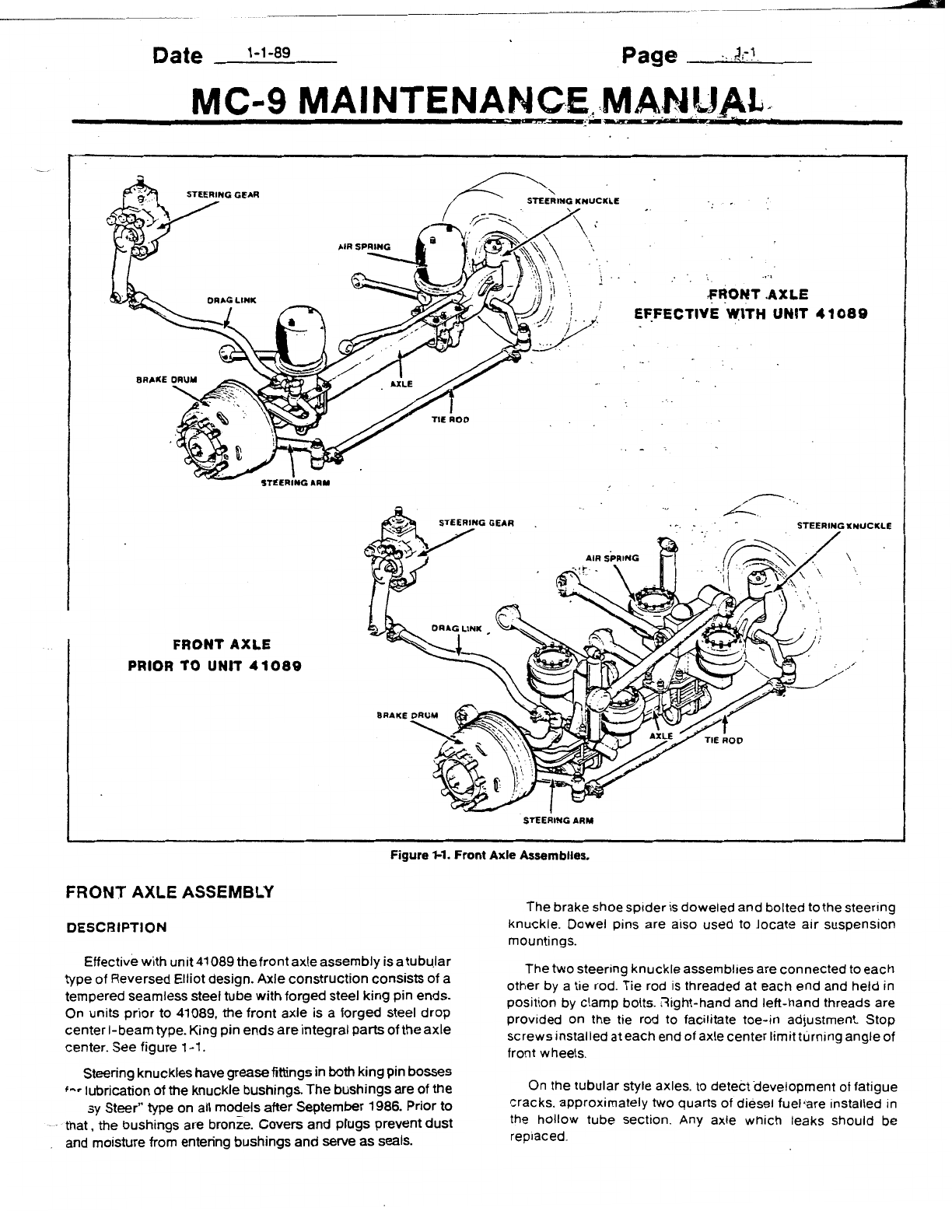

MC-9

MAINTENANCE

MANUAL

Steering

knuckles

are bushed in the

upper

and

lower

pm

bosses

so

thatthey mayturn fr:eel¥.about the pins. Bushings

are

grooved

on

the inside to

allow

grease to flow uniformly to

high-pressure

areas. Grease

fittings

areinstalled

at

both

upper

and

lower

king pin bosses.

On

the

earlierMC-9

front

axles

the

tapered

steering

knuckle

pins are

drawn

into

the

axle

center

by

tightening

the

nut

at

the

upper

end

of

the

pin. Onthe laterMC•9s a

straight

type

knuckle

pin is used.

The

straighttype pin

i~

held

in

placeby

draw

keys

in

the knuckle. "

Wheel bearings. air suspension. steering and brake parts

which

are

mounted

on thefrontaxlearedescribe<;l in

the

appli-

cable

sections

of this manual.

LUBRICATION

Periodic

lubrication

according

to the recommendations in

the

lubrication

section of this manual should

be

carried out.

Points

which

require lubrication are the steering

knuckle

pins.

tie-rod

ends

and drag link ends. These are

provided

with

grease fittings for pressure lubrication.

MAINTENANCE

Periodic

mspection

of the front axle assembly

should

be

made

to

see that all. bolts are tight and that

no

damage or

distortion

has taken place. Suspension support stud nuts.

U-bolt

nuts.

tie-rod

armand steering arm nuts. and stop

screws

should

be

checked

and tightened

1f

necessary to the torque

specifications

shown

at

the end

of

this section.Attention

should

also

be

given

·to

the

condition

of the steering

knuckle

pin

and

bushings.

If excessive looseness

is

found• at

this

point. the

bushings

and

pins should be replaced.

The

axle

manufacturer recommends that the

bronze

or

"Easy

Steer"

king

pin

bushings

be

replaced

when

the range

of

side-to-side

tire movement reaches

.030

inch

or

when the

bushings

are

worn

to amaximumof .010

inch

on their diameter.

NOTE:

These measurementsaremade with

thewheel bearingstightened on

the

spindle.

With

new

bushings

installed. the range of

side-to-side

tire

movement

should

not exceed .010 inch maximum. Refer to

Figure 1-2.

Looseness

in the steering linkage

under

normal steering

toads is

sufficient

cause to immediately

check

all

pivot

pomts

tor wear. regardless of accumulated m!leage. Steering

linkage

p,vot

points

should

be checked each time the axle assembly

,s

lubricated.

If

any

1nd1cat1on

of

lateral movement is found.

cross

tube

ends

should

be removed for inspection. Looseness

at

the

steering

linakge

pivot points can be visually detected

during

movement of the ven1cle steering wheel.

Steering knuckles. king pins. and

bushings

may

be

replaced

without

removing the axle from the coach.

.010 INCH MAX.

SIDE-TO-SIDE

TIRE MOVEMENT

FRONT

OF TIRE

NEW

BUSHINGS

.030

INCH

MAX.

SIDE-TO-SIDE

TIRE MOVEMENT

(OR BUSHING

DIAMETER

WORN .010")

..,&.-·----

FRONT OF TIRE

WORN

BUSHINGS

Figure 1-2. Side-To-Side

Tire

Movements With New And

With Worn King Pin Bushings.

If extensive overall

work

or

straightening of

the

front

axle

center

,s

necessary. the axle should. of course. be removed.

WARNING:

Do not attempt to repair,

remove or reinstall front axle with the vehi-

cle supported by jacks only.

FRONT

AXLE REMOVAL (Prior to

unH

41089)

To

remove the entire

front

axle assembly first

block

the

rear

wheelsto preventthevehiclefrom rolling.Raisethe frontend

of

the

coach

with jacks until

the

bottom of the

coach

body is

approximately

18"

(45

7.2

mm) from the floor.

Block

the body in

this position as indicated in Section 3

under

Coach

Jacking

Points.

CAUTION:

Do not raise the body in such a

way that the entire weight of the front axle

will hang on the suspension bellows

assemblies. Damage to the bellows may

result.