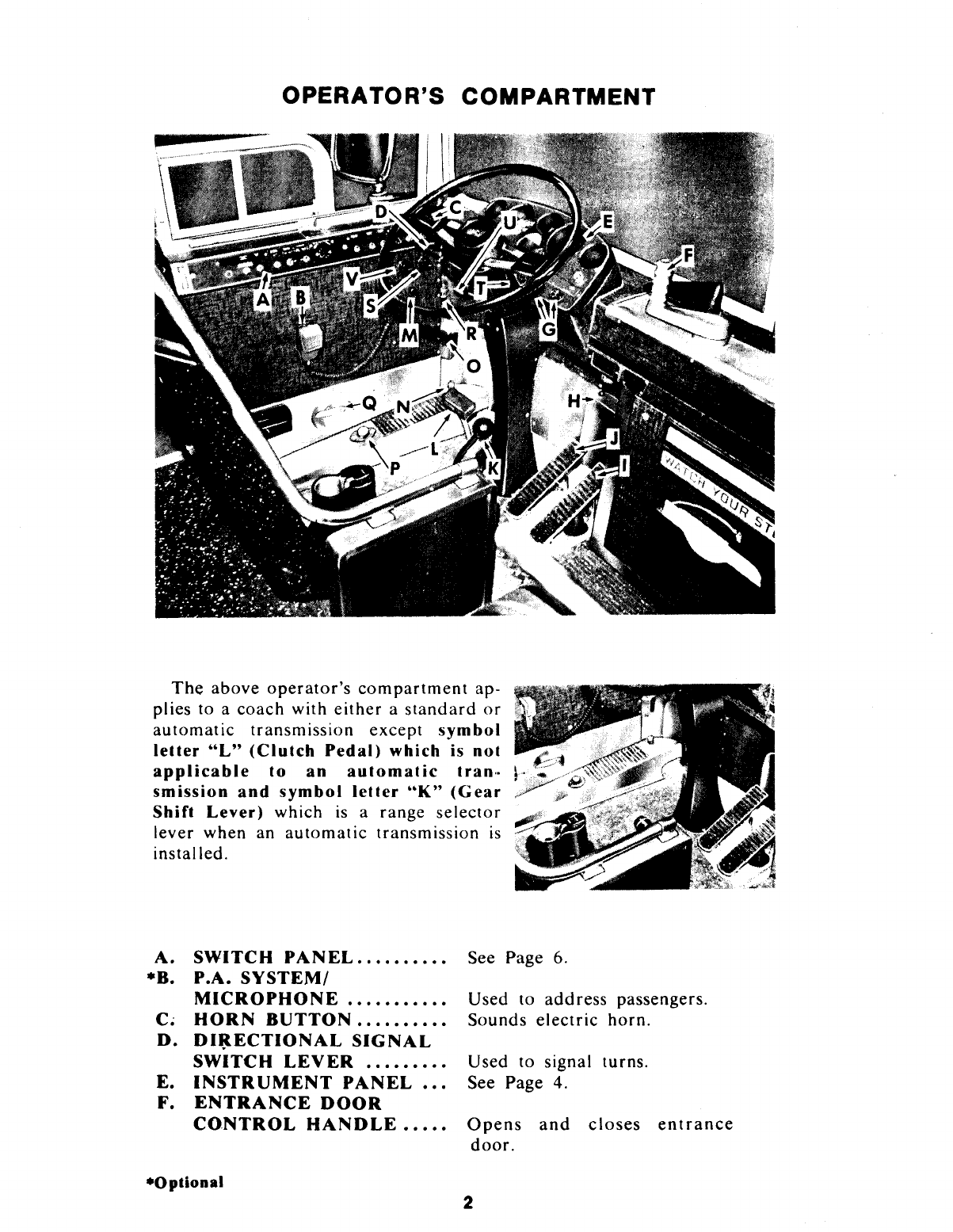

C. WATER TEMP.

GAUGE

..

D.

AIR

PRESSURE

GAUGE.

E.

HEADLIGHT

HI-BEAM

Indicates

engine

temperature.

Indicates

coach

air

system

pressure.

TELL-TALE

..

. . . . . . . . . . . .

Glows

when

headlight

hi-beams

are

on.

F. "HOT ENG" TELL-

TALE

. . . . . . . . . . . . . . . . . . . . . Flashes

and

buzzes when engine

overheated.

G. "LOW OIL" TELL-

TALE

. . . . . . . . . . . . . . . . . . . . . Flashes

and

buzzes when oil

pressure

too low.

*H. "LOW WATER" TELL-

Flashes

and

buzzer

operates

TALE

. . . . . . . . . . . . . . . . . . . . . when

water

level

too

low.

I.

"LOW

AIR"

TELL-

TALE

. . . . . . . . . . . . . . . . . . . . . Flashes

and

buzzes when

coach

air

pressure

too

low.

J.

TRAILING

AXLE

BELLOWS LOW

AIR

TELL-TALE . . . . . . . . . . . . . .

Glows

when

air

pressure

low

in

trailing

axle

bellows.

K. "EMERG. BRAKE"

TELL-TALE . . . . . . . . . . . . . . Flashes when

emergency

brakes

are

applied.

L.

"A/C HI-LO" TELL-

TALE

....................

.

M.

"TURN

LIGHT" TELL-

TALE

....................

.

N.

"HAZARD

WARNING"

Glows

or

flashes

when

air condition-

ing

system

malfunctions

Flashes when

turn

signals

are

on.

TELL-TALE . . . . . . . . . . . . . . Flashes when

hazard

warning

is

operated.

*O. "LOW FUEL" TELL-

TALE

. . .

..

. . . . . . . . . . . . . . . .

Glows

when fuel supply

is

low.

P.

"B.U. LITE" TELL-

TALE

...

-.

. . . . . . . . . . . . . . . . .

Flashes

when

back-up

lights

are

on.

Q.

"NOT

GEN." TELL-

TALE

. . . . . . . . . . . . . . . . . . . . .

Glows

when

generator

not

charging.

*R.

"LAV.

EM

ERG."

TELL-TALE

.............

.

S.

"HEAT

ON" TELL-

Glows

and

buzzes

if

emer-

gency

button

in

lavatory

is pressed.

TALE

. . . . . . . . . . . . . . . . . . . . . .Glows when heating system

operating.

T. "STOP LIGHT"

TELL-TALE

...•..........

*U.

"RETARDER"

TELL-

TALE

....................

.

•Optional

Glows

when

both

rear

stoplights

are

on.

Glows

when switched on.

5