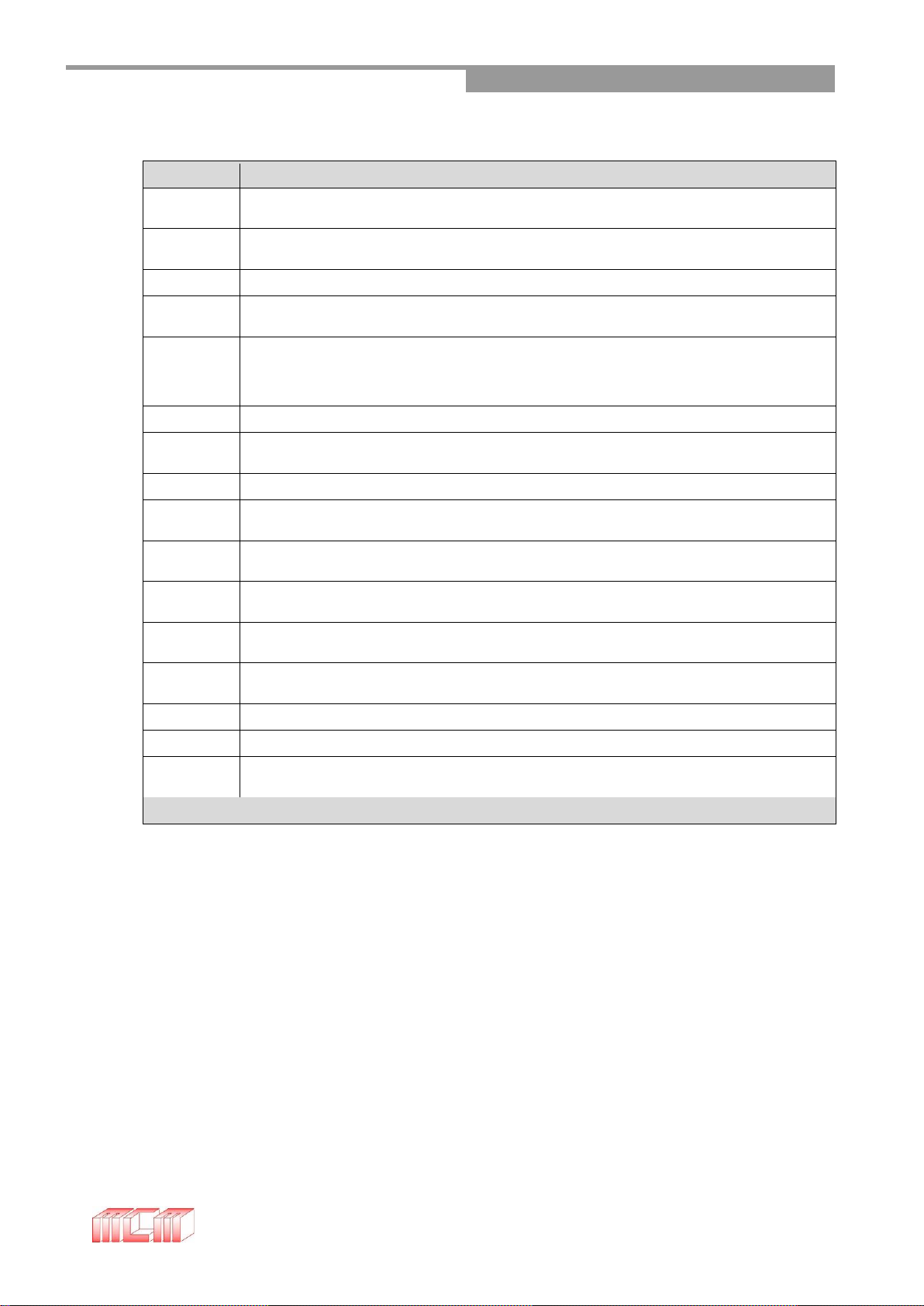

CONTENTS OF SECTION 1 (INTRODUCTION)

1. GENERAL INFORMATION ___________________________________________ 4

1.1. This document ____________________________________________________________ 4

1.1.1. Language used_______________________________________________________________________________ 5

1.1.2. Consultation _________________________________________________________________________________ 5

1.1.3. Conventions on the symbols and notes on the graphic display _________________________________________ 5

1.1.4. Definitions __________________________________________________________________________________ 6

1.2. Liability _________________________________________________________________ 7

1.3. Copyright ________________________________________________________________ 7

1.4. Testing __________________________________________________________________ 7

1.5. Warranty ________________________________________________________________ 8

1.6. Court of jurisdiction ________________________________________________________ 8

1.7. Applied technique legislation and certifications ___________________________________ 8

2. INTENDED CONDITIONS OF USE AND ELEMENTS PRESENT ________________ 9

2.1. Description of the supply ____________________________________________________ 9

2.2. Identification plate_________________________________________________________10

3. USER DUTIES ___________________________________________________ 11

3.1. Installation environmental conditions __________________________________________11

3.2. Lighting _________________________________________________________________12

3.3. Airborne acoustical noise emissions ____________________________________________12

3.4. Supporting surface _________________________________________________________12

4. SAFETY________________________________________________________ 13

4.1. General safety requirements _________________________________________________13

4.2. Contraindications __________________________________________________________14

4.3. Exclusions _______________________________________________________________14

4.4. The operator______________________________________________________________14

4.5. Safety components_________________________________________________________16

4.6. Residual risks and safety signs________________________________________________16

4.7. Personal protective equipment (PPE)___________________________________________18

4.8. Emergency shutdown _______________________________________________________19

4.8.1. Restoring operations after an emergency stop _____________________________________________________ 19

4.9. Specific safety measures ____________________________________________________20

4.9.1. Safety measures in case of malfunctions, emergencies or accidents. ___________________________________ 20

4.9.2. Safety measures if the machine malfunctions. _____________________________________________________ 20

4.9.3. Emergency safety measures in the work environment. ______________________________________________ 20

4.9.4. Safety measures in case of injuries or accidents. ___________________________________________________ 20

4.9.5. Safety measures when working at a height. _______________________________________________________ 20