Commercial in confidence

S4 RESCUE SART service manual Issue 2

mcmurdo

mcmurdomcmurdo

mcmurdo

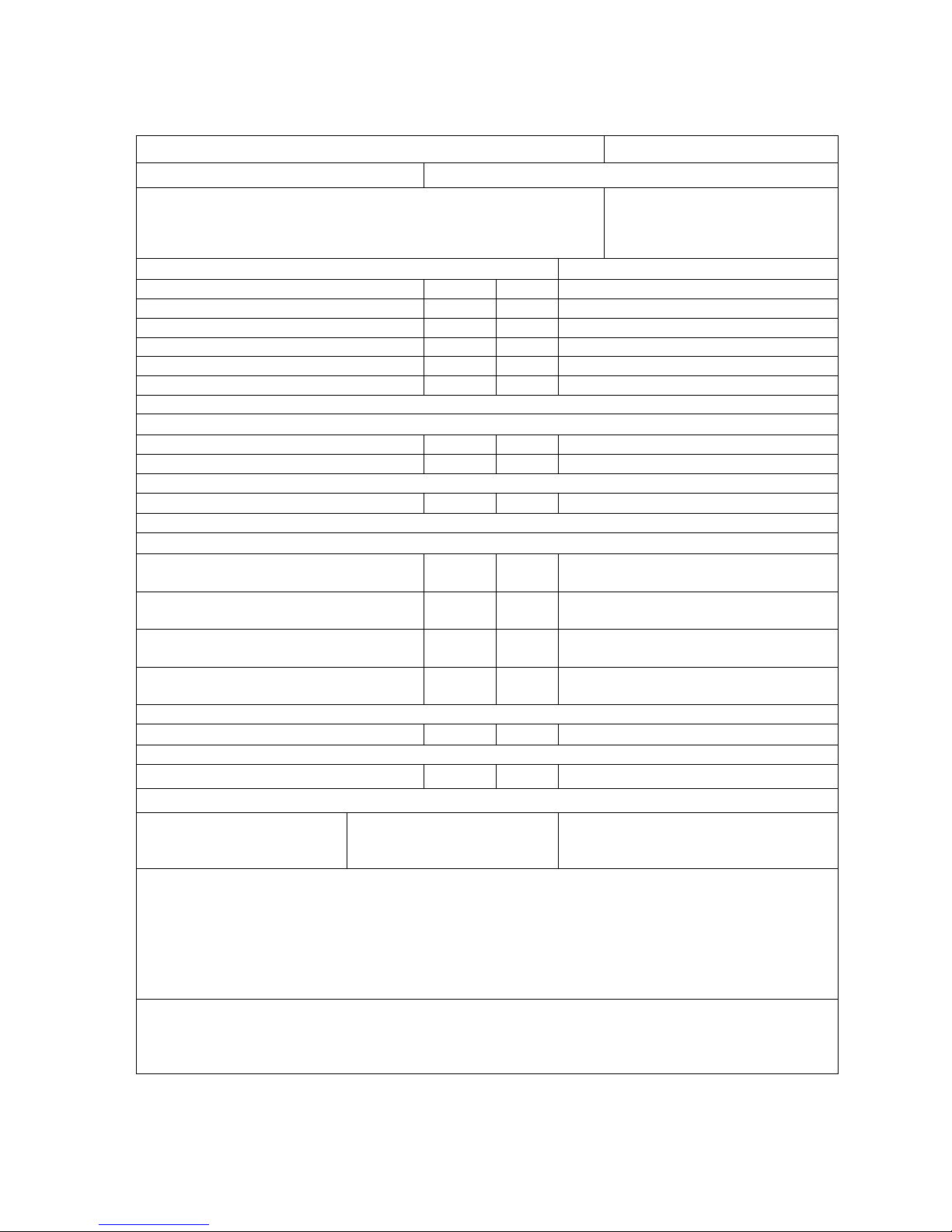

Contents

1. Introduction........................................................................................................................... 1

1.1. Scope ............................................................................................................................. 1

1.2. Applicability..................................................................................................................... 1

1.3. Revision history .............................................................................................................. 1

1.4. Servicing equipment ....................................................................................................... 2

1.5. Safety notices ................................................................................................................. 3

2. Assessment .......................................................................................................................... 5

2.1. Maintenance tas s.......................................................................................................... 5

2.2. Routine testing................................................................................................................ 5

2.3. Assessment .................................................................................................................... 5

3. Maintenance rocedures ..................................................................................................... 8

3.1. Mechanical inspection .................................................................................................... 8

3.2. Self test procedure ......................................................................................................... 8

3.3. Functional testing ........................................................................................................... 9

3.4. Frequency testing ........................................................................................................... 9

3.5. Lea testing .................................................................................................................. 12

3.6. Battery replacement ..................................................................................................... 13

4. Fault finding ........................................................................................................................ 17

5. Re air rocedures.............................................................................................................. 18

5.1. Replace O-ring ............................................................................................................. 18

5.2. Replace PCB ................................................................................................................ 18

5.3. Re-tune PCB ................................................................................................................ 19

5.4. Factory return procedure .............................................................................................. 19

6. S ares.................................................................................................................................. 20

A endix 1: S ecification ......................................................................................................... 21

7. Product Warranty ............................................................................................................... 22

8. End of Life Statement......................................................................................................... 23

8.1. Battery Removal ........................................................................................................... 23

8.2. Disposal........................................................................................................................ 23

This document is McMurdo copyright (©) and contains proprietary owned intellectual property rights and confidential data. All

rights are strictly reserved. The information must not be used except for the agreed purpose. Unauthorized use, reproduction

or issue to any third party is not permitted without the prior written authority of McMurdo. This document is to be returned to

McMurdo when the agreed purpose is fulfilled.