●

Always work at a safe speed taking account of the conditions i.e.: terrain,

highway proximity and obstacles around and above the machine.

●

Extra special attention should be applied to Overhead Power Lines. Some of

our machines are capable of reach in excess of 8 metres (26 feet) this means

they have the potential to well exceed, by possibly 3 metres (9’ 9”), the lowest

legal minimum height of 5.2 metres from the ground for 11,000- and 33,000-

volt power lines. It cannot be stressed enough the dangers that surround this

capability, it is therefore vital that the operator is fully aware of the maximum

height and reach of the machine, and that they are fully conversant with all

aspects regarding the safe minimum distances that apply when working with

machines in close proximity to Power Lines. (Further information on this subject

can be obtained from the Health & Safety Executive or your Local Power

Company).

●

Always disengage the machine, kill the tractor engine, remove and retain the

key before dismounting for any reason.

●

Always clear up all debris left at the work area; it may cause hazard to others.

●

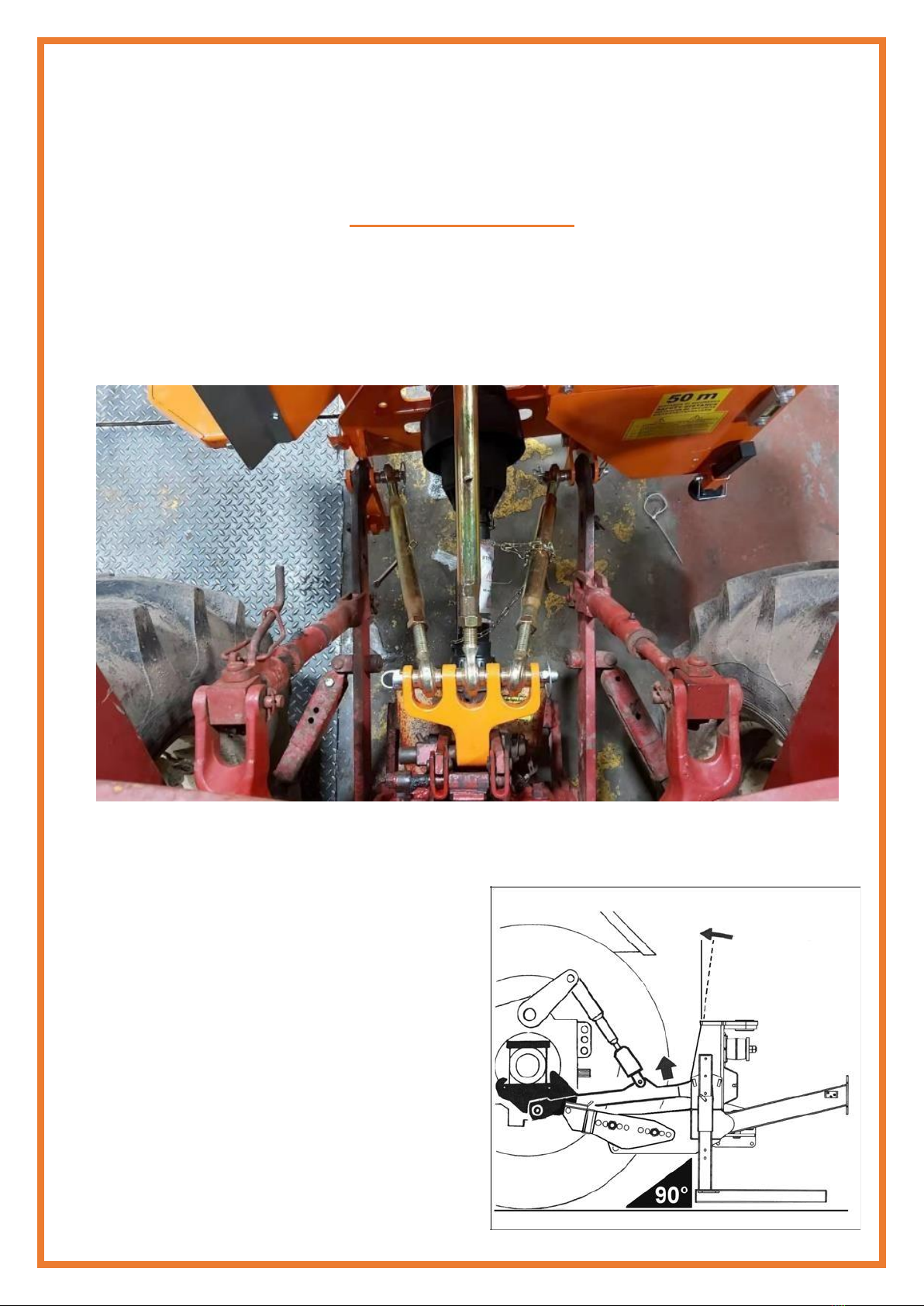

Always ensure when you remove your machine from the tractor that it is left in

a safe and stable position using the stands and props provided and secured if

necessary.

●

Beaware of the articulated arms when adjusting towards the limitsof their travel

-

in certain positions, arms could make contact with hydraulic ram components

and cause damage to the machine.

WHEN NOT TO USE THIS MACHINE:

●

Never attempt to use this machine if you have not been trained to do so.

●

Never use a machine until you have read and understood the operator

handbook, are familiar with, and practiced the controls.

●

Never use a machine that is poorly maintained.

●

Never use a machine if guards are missing or damaged.